The Best Stainless Steel Pipe Polishing Machines in China

In recent years, China has emerged as a global leader in manufacturing various industrial equipment, including stainless steel pipe polishing machines. These machines are essential for achieving a smooth and aesthetically pleasing finish on stainless steel pipes, enhancing both their appearance and corrosion resistance. In this article, we will explore the best stainless steel pipe polishing machines in China, highlighting their features, advantages, and the factors to consider when choosing the right machine for your needs.

Importance of Polishing Stainless Steel Pipes

Stainless steel is widely used in industries ranging from construction to food processing due to its strength, durability, and resistance to corrosion. However, raw stainless steel pipes often have imperfections, such as rough surfaces, scratches, or oxidation. Polishing not only improves the visual appeal of the pipes but also removes these imperfections, ensuring better hygiene and longevity of the material.

Features of the Best Polishing Machines

When it comes to selecting a stainless steel pipe polishing machine, several key features should be considered

1. Versatility The best polishing machines can handle a range of pipe sizes and shapes. Whether you need to polish round, square, or rectangular pipes, a versatile machine will provide better efficiency and adaptability.

2. Automation Modern polishing machines often come equipped with automated features, including programmable settings for different polishing processes. This automation allows for consistent results and reduces the labor involved in the polishing operation.

3. Material Quality High-quality stainless steel pipe polishing machines are generally made with robust and durable materials, ensuring longevity and minimal maintenance. Machines that use advanced technologies for construction often deliver superior performance.

4. Polishing Types Different machines may offer various polishing techniques, including belt polishing, buffing, or vibratory polishing. Selecting a machine based on the desired polishing technique can significantly affect the final finish.

5. Ease of Use User-friendly machines with intuitive interfaces make it easier for operators to learn and maintain the equipment, minimizing training time and operational errors.

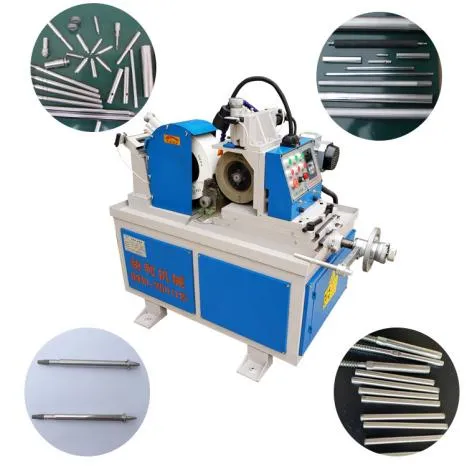

best stainless steel pipe polishing machine china

6. Safety Features Safety is paramount in any industrial operation. The best polishing machines usually include safety features such as emergency stop buttons, protective guards, and automatic shut-off functions.

Leading Manufacturers in China

Several manufacturers in China are known for producing high-quality stainless steel pipe polishing machines. Companies like Jinan Jincheng Machinery, Xiantao Yida Machinery, and Jiangyin Dingbo Technology stand out for their innovative designs and reliable performance. These manufacturers provide a variety of options that cater to different industrial needs, ranging from small workshop setups to large-scale production facilities.

Factors to Consider Before Purchase

Before investing in a stainless steel pipe polishing machine, it's crucial to assess your specific needs

1. Production Volume Consider your production scale. High-volume production may necessitate more advanced and automated machines, while smaller operations could benefit from simpler models.

2. Budget Polishing machines come in a wide price range. Establishing a budget will help narrow down your options and ensure you get the best value for your money.

3. Space Evaluate the space available in your workshop or facility. Ensure that the machine fits comfortably in your operational area and that there's enough room for safe operation.

4. Technical Support Choose a manufacturer that provides excellent customer service and technical support. This can be invaluable in case you encounter issues or need maintenance assistance.

Conclusion

Stainless steel pipe polishing machines are vital for industries that rely on high-quality finishes for their products. With China's vast array of manufacturers providing advanced machinery, businesses have access to some of the best options available globally. By considering key features, evaluating leading manufacturers, and understanding your own needs, you can confidently select the right polishing machine that will enhance the efficiency and effectiveness of your operations. Investing in a high-quality polishing machine not only improves product quality but can also lead to increased customer satisfaction and market competitiveness.