The Evolution and Significance of Bar Polishing Machines in Modern Manufacturing

In the world of manufacturing, the importance of surface finish cannot be overstated. Industries rely on high-quality components to ensure the efficiency and durability of their products. One of the essential tools in achieving superior surface finishes are bar polishing machines. These machines have transformed the way manufacturers improve the aesthetics and performance of metal bars and rods, impacting various sectors from automotive to aerospace.

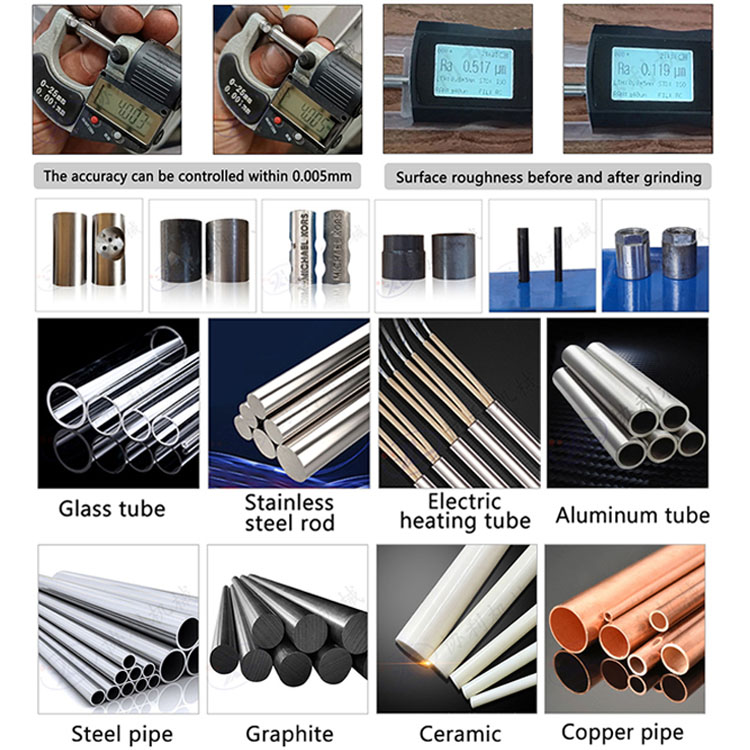

At its core, a bar polishing machine is designed to enhance the surface quality of metal bars, typically made from materials like stainless steel, aluminum, or brass. The process involves removing surface imperfections, which may include scratches, rough spots, and oxidation, thereby resulting in a smoother and more visually appealing product. This is especially critical in applications where the surface finish can affect the functionality of the component, such as in hydraulic systems, where the smoothness ensures better fluid flow.

The process of bar polishing can significantly extend the life of the manufactured products. By removing contaminants and preparing a metal surface that is less prone to corrosion, these machines contribute to the overall performance of the final components. For instance, in the automotive industry, polished bars are often used in critical parts such as rods, tubes, and shafts, where strength, efficiency, and resistance to wear are paramount.

Technological Advancements

Over the years, bar polishing technology has evolved significantly. The early machines were primarily manual and labor-intensive, requiring skilled operators to achieve satisfactory results. However, with advancements in technology, modern bar polishing machines are now automated and equipped with sophisticated features that improve both efficiency and precision. Computer Numerical Control (CNC) technology has been integrated into many of today’s machines, allowing for more consistent finishes and the capability to maintain tight tolerances.

Modern bar polishing machines also utilize a variety of polishing methods, including mechanical polishing using belts or discs, chemical polishing, and electropolishing. Each method has its unique applications and benefits. For instance, mechanical polishing is effective for removing substantial material and achieving a high-gloss finish, while electropolishing is ideal for achieving a uniform surface finish and enhancing corrosion resistance.

bar polishing machine company

Environmental Considerations

As awareness of environmental sustainability grows, manufacturers of bar polishing machines have also begun to consider the environmental impact of their products. Advances in technology are not only focused on efficiency and speed but also on reducing waste and energy consumption. For example, some machines now incorporate closed-loop systems that recycle polishing compounds and reduce the amount of waste generated during the process. This commitment to sustainability is not only beneficial for the planet but also for companies looking to improve their eco-friendly practices.

Key Players in the Bar Polishing Machine Market

The bar polishing machine market is highly competitive, with several companies leading in innovation and technology. These companies focus on producing high-quality machines that cater to the unique requirements of various industries. They offer a range of models, from simple, cost-effective solutions for small workshops to sophisticated, multi-functional machines for large manufacturers.

Customer service and machine support are also crucial factors that companies consider when selecting a bar polishing machine provider. A company’s reputation for quality, reliability, and after-sales support can make a significant difference in a manufacturer’s choice.

Conclusion

In conclusion, bar polishing machines play a crucial role in the manufacturing sector, significantly impacting the quality and longevity of products. As industries continue to demand higher standards and efficiencies, the evolution of bar polishing technology will likely keep pace, incorporating new innovations that enhance both performance and sustainability. For manufacturers, investing in advanced bar polishing machines is not just about achieving better surface finishes; it’s about ensuring the overall quality and competitiveness of their products in a global market.