Field Notes from the Shop Floor: A Practical Look at the bar centerless grinder

I spent a week in Xihuang Industrial Park, Xingwan Town, Ren County, Xingtai City, Hebei, watching the “Round Bar Polishing Machine Factory Price” line run bars and tubes back-to-back. To be honest, the name undersells it. It’s a compact, industrial workhorse built for pipes, stainless round, carbon steel bar, even aluminum. And yes, it’s very much a bar centerless grinder in how it feeds, stabilizes, and finishes long stock—just optimized for high-finish polishing.

What’s trending (and what actually matters)

Across shops, three trends keep coming up: automated setup (less fiddling with guides), in-line surface metrology, and greener coolant management. Many customers say consistent Ra is now a line item, not a “nice-to-have.” Interestingly, some buyers still debate between belt-based polish heads and vitrified wheels. In practice, belts are winning for finish flexibility, while wheels carry the day for aggressive stock removal. This machine supports either route, which is practical.

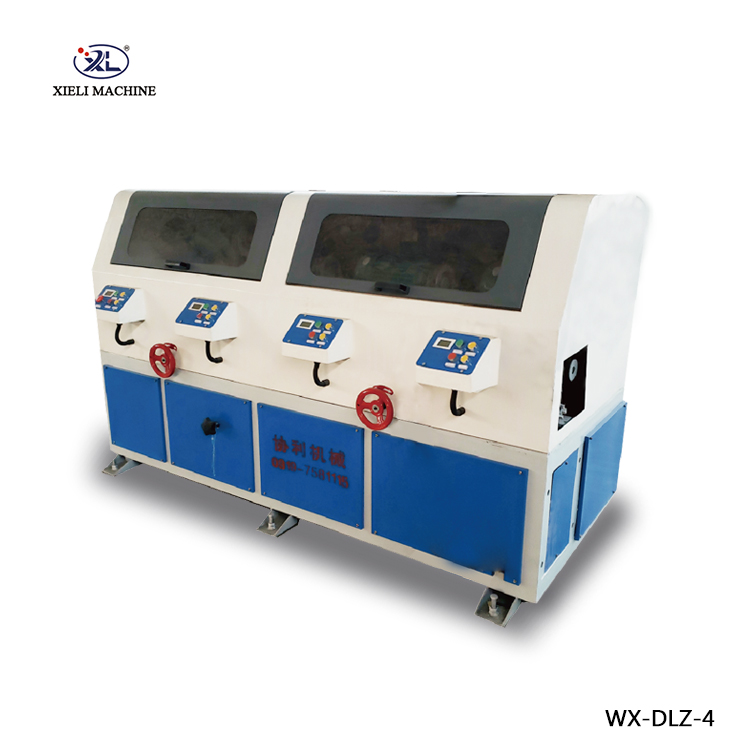

Product snapshot: Round Bar Polishing Machine (Factory Price)

Origin: Xingtai, Hebei, China. The machine polishes the outer surface of round tubes and bars: stainless, carbon steel, aluminum, you name it. The structure is straightforward—powered feed rollers, adjustable guide shoes, multi-head polishing stations, flood coolant (optional), and dust extraction ports. It’s simple enough to run, but the results, if you dial it in, are surprisingly premium.

| Parameter | Typical spec (≈ / real-world may vary) |

|---|---|

| Bar/Tube Ø range | 6–120 mm (custom up to ≈180 mm) |

| Finish capability | Ra ≈ 0.2–0.8 μm with fine belts; mirror options |

| Feed speed | 2–15 m/min adjustable |

| Abrasive config | Abrasive belts (60–1200 grit) or wheel heads |

| Installed power | ≈ 12–30 kW depending on heads |

| Coolant/dust | Wet or dry; external dust collector recommended |

Process flow (how shops really run it)

- Material in: SS304/316, carbon steel, aluminum; incoming straightness checked per ASTM A108 guidance.

- Roughing: coarse belt (P80–P180) for weld seam leveling/scale removal.

- Sizing/stability: guide shoes and top rollers center the work like a bar centerless grinder; runout monitored.

- Finishing: P320–P800, sometimes nonwoven; wet pass to control heat tint.

- QC: Ra per ISO 21920/ISO 4287; hardness (if needed) per ASTM E18; wheel/belt safety per EN 12413; machine guarding per OSHA 1910.215.

Service life: belts last ≈ 8–40 hours depending on alloy and pressure; guides are consumables (polymer/bronze) with multi-month life in two-shift use. Typical Ra improvement from 1.2 μm to 0.3 μm is common in one pass train.

Applications, advantages, customization

- Industries: furniture/architectural rail, auto shafts, oil & gas mandrels, medical carts (not implants), food equipment.

- Advantages: steady finish at speed, minimal operator skill curve, small footprint, saner consumable cost.

- Customization: additional heads, wet-only conversion, servo feed, in-line eddy-current flaw check, CE packages, bar loaders up to 6–8 m.

| Vendor | Strengths | Watch-outs |

|---|---|---|

| Xieli (Hebei) | Value pricing, flexible builds, quick parts | Spec sheets vary by batch; confirm Ra at FAT |

| EU brand A | Top metrology, CE documentation depth | Higher cost, longer lead times |

| Local integrator | On-site support, custom fixturing | Depends on chosen modules; QC is key |

Field notes and mini case studies

Automotive Tier-2 (Guangdong): switched from manual wheel finish to this bar centerless grinder; Ra moved from ≈0.9 μm to 0.35 μm at 8 m/min, scrap down 2.1% to 0.6%. EU tube mill: added wet head, achieved “hairline” cosmetic finish on 304 tubes meeting customer’s ISO 21920 profile spec. Feedback is consistent: stable guides matter more than you think.

Certifications: factory offers CE options; ISO 9001 documentation available on request (always verify scope). Safety guarding and wheel/belt ratings should be cross-checked against EN 12413 and OSHA 1910.215 before commissioning, especially if you tweak speeds.

Bottom line

If you’re chasing cosmetic consistency with industrial throughput, this machine—and others in its class—delivers. It’s not magic, but with sane setup, you’ll get repeatable finish, less operator fatigue, and predictable consumable spend. Actually, that predictability is what busy shops value most.