The Rise of Automatic Stainless Steel Polishing Machine Companies

In today’s fast-paced industrial landscape, the demand for high-quality, efficient processing equipment has never been higher. One particular area that has seen exponential growth is the automatic stainless steel polishing machine market. Companies specializing in this technology have become increasingly crucial as industries seek to enhance productivity and maintain product quality.

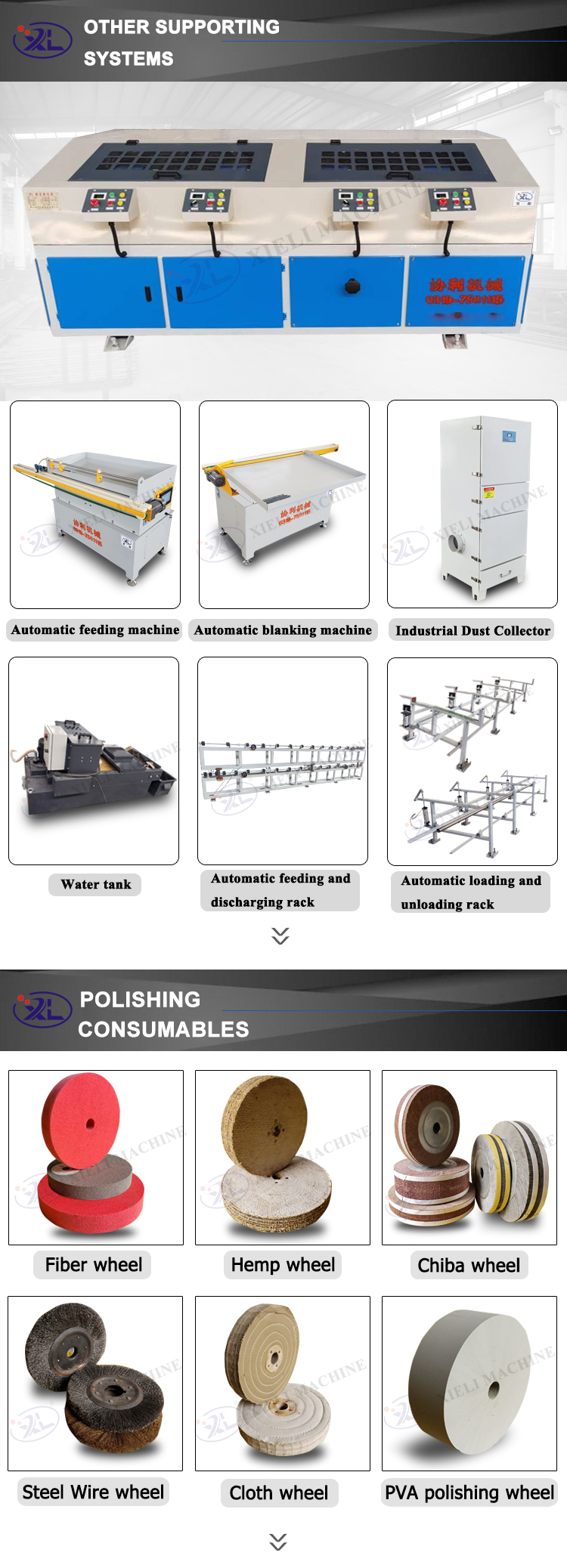

Automatic stainless steel polishing machines are designed to refine the surface of stainless steel products, ensuring a smooth and aesthetically pleasing finish. These machines significantly reduce manual labor requirements, allowing for precise and consistent results. This automation offers various advantages, including superior efficiency, reduced operational costs, and the ability to maintain strict quality control standards.

One of the primary drivers behind the emergence of automatic polishing machine companies is the manufacturing sector's need for high-speed production. Industries such as automotive, aerospace, and construction frequently utilize stainless steel due to its durability and resistance to corrosion. As these industries continue to expand, the demand for polished stainless steel components—such as fixtures, pipes, and decorative elements—skyrockets. Companies that manufacture polishing machines have stepped up to meet this demand, offering a range of solutions tailored to different applications.

The technology behind automatic polishing machines has vastly improved in recent years. Modern machines utilize advanced robotic systems and versatile polishing heads, enabling them to adjust to various shapes and sizes of stainless steel products. This adaptability provides manufacturers with the flexibility needed to handle diverse production needs. Some machines even incorporate Artificial Intelligence and machine learning algorithms, allowing for real-time adjustments to optimize the polishing process further.

automatic stainless steel polishing machine companies

Moreover, automatic stainless steel polishing machine companies are committed to sustainability. Many of these machines are designed to minimize waste and energy consumption. Innovations such as closed-loop systems for abrasive materials and the use of eco-friendly polishing agents help reduce the environmental impact of the polishing process. As sustainability becomes a pivotal concern for industries worldwide, companies that prioritize eco-friendly practices are finding a competitive edge.

In addition to the technological advancements and sustainability efforts, the competition among automatic stainless steel polishing machine companies has led to improved customer service and support. Many firms now offer comprehensive training for operators and maintenance personnel, ensuring that clients can optimize the use of their machines. This focus on customer satisfaction strengthens long-term relationships and fosters loyalty within the industry.

As we look to the future of automatic stainless steel polishing machine companies, we can expect further innovations and improvements. With the increasing integration of smart technologies and a growing emphasis on sustainable practices, these companies are poised to revolutionize the way we process stainless steel. The convergence of efficiency, quality, and eco-friendly initiatives will undoubtedly continue to drive growth in this vital sector.

In conclusion, the landscape of automatic stainless steel polishing machine companies is evolving rapidly. With a focus on automation, sustainability, and customer service, these companies are well-positioned to meet the future demands of various industries and contribute to advancements in manufacturing processes.