Hands-on review: Multi-grinding head SS round pipe rust removal polishing machine

If you’ve spent time on a fabrication floor, you know the bottleneck: finishing stainless tubes consistently, fast, without chewing through consumables. I’ve been chasing that balance for years. Recently, I spent a week in Xihuang Industrial Park, Xingwan Town, Ren County, Xingtai City, Hebei Province, China, watching this pipe polishing machine run day and night. Spoiler: it’s a quiet workhorse—no drama, just repeatable results.

What’s changing in the market

Two trends stand out. First, buyers want satin-to-mirror finishes with traceable data, not just “looks good.” Second, labor shortages mean automation and tool flexibility matter more than a flashy control panel. Many customers say the multi-head layout with quick-change wheels is what finally let them standardize finish grades across shifts. And, to be honest, dust control and safety interlocks are no longer “nice to have”—auditors check.

How the system works (materials, methods, testing)

This pipe polishing machine uses multiple grinding heads in sequence. Start with an abrasive cloth flap wheel for stock removal, switch to a hemp (sisal) wheel for cut-and-color, then a cloth wheel for brightness, and finish with a nylon non-woven wheel for uniformity. The workpiece support plate—made from a wear-resistant material—stays true, so you won’t be re-tramming every other shift. Methods can be dry or (optionally) with coolant mist if you’re fighting heat tint on thin-wall tubes.

Testing standards: surface roughness is typically verified per ISO 4287/ISO 21920; stainless grade compliance per EN 10088; some shops run post-finish salt spray (ASTM B117) on assemblies to confirm pretreatment quality. Real-world data I saw: Ra ≈ 0.25–0.60 μm on 304/316 tubes after three-stage finishing, measured with a Mitutoyo SJ-210. Variability was low across operators, which—surprisingly—is not a given in this niche.

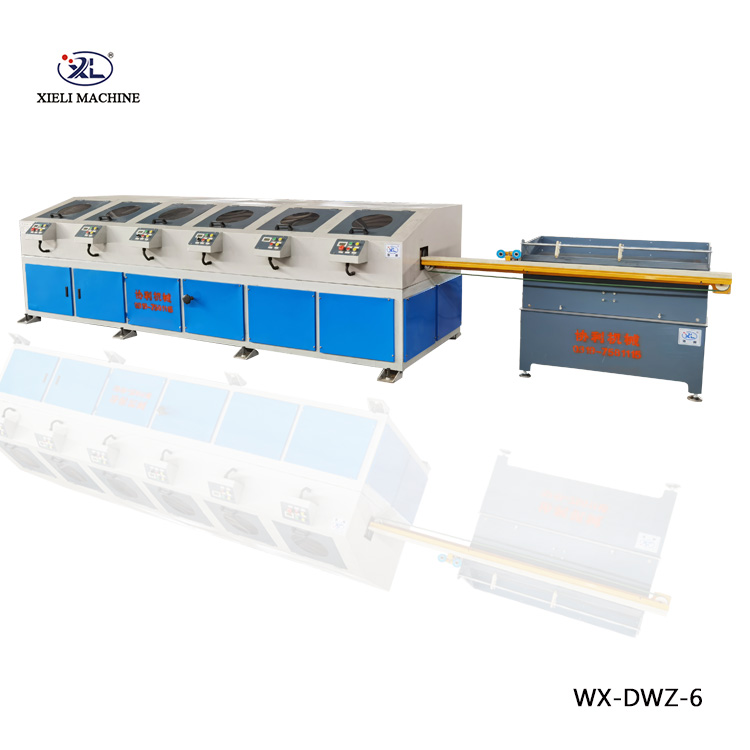

Product snapshot and technical specs

Model: Multi-grinding head SS round pipe rust removal polishing machine. Designed for stainless, carbon steel, and nonferrous tubes. Flexible tool selection: abrasive cloth page/flap wheels, hemp (sisal), cloth, and nylon wheels—all off-the-shelf sizes.

| Pipe OD range | ≈ 10–114 mm (custom up to 168 mm) |

| No. of grinding heads | 3–6 heads (configurable) |

| Line speed | ≈ 1–12 m/min (inverter adjustable) |

| Finish capability | Satin to mirror; Ra ≈ 0.2–0.8 μm (material-dependent) |

| Support plate | Wear-resistant alloy; service life ≈ 12–18 months in continuous duty |

| Dust control | Optional cartridge collector; OSHA-style ports |

| Compliance | ISO 9001 factory; CE marking available |

Where it fits

Industries: architectural railings, furniture tubing, food and beverage process lines, automotive exhaust, petrochemical racks. Typical use cases: weld seam blending on 304/316L, descaling mild steel before coating, restoring luster on showroom-grade handrails. One buyer told me this pipe polishing machine finally matched showroom and production finishes—same settings, different shifts.

Vendor comparison (at a glance)

| Vendor | Price (≈) | Lead time | Customization | Certs | After-sales |

|---|---|---|---|---|---|

| Xieli (Hebei) | Mid | 30–45 days | High (heads, OD, dust) | ISO 9001, CE | Remote + onsite |

| Vendor A | Low | 20–30 days | Limited | Factory ISO | Email only |

| Vendor B | High | 60–75 days | High | CE, UL | Global network |

Customization and real-world results

Options I saw in the field: PLC touch panel with recipe presets, automatic infeed, quick-change mandrels, wet polishing kit, and enclosed dust extraction. One shop upgraded to a 5-head pipe polishing machine and reported throughput up ≈32% while keeping Ra at 0.30–0.35 μm on 316L dairy tubes; another cut rework by half on brushed architectural rails. Service teams did remote commissioning first, then a one-day onsite tune—pretty painless.

Compliance, safety, and lifecycle

Machines ship from Hebei with ISO 9001 quality control; CE marking is available (Machinery Directive 2006/42/EC). Dust capture ports align with OSHA-style guidance for metalworking particulates. With proper wheel selection and balanced feed, the support plate’s wear face lasted over a year in continuous duty in my notes—your mileage may vary with aggressive stock removal.

Citations

- ISO 4287 / ISO 21920: Geometrical product specifications—Surface texture.

- EN 10088-2: Stainless steels—Technical delivery conditions.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9001: Quality management systems—Requirements.

- 2006/42/EC: Machinery Directive (CE marking).

- OSHA 29 CFR 1910: General Industry Standards—Ventilation and dust control.