The Significance and Functionality of Aluminum Tube Polishing Machines

In the realms of manufacturing and metalworking, the quest for excellence in product finish is paramount. Among the myriad of techniques employed to achieve a polished appearance, aluminum tube polishing stands out as a crucial process, especially in industries where aesthetics and precision matter, such as aerospace, automotive, and decorative applications. The utilization of aluminum tube polishing machines has become essential in achieving high-quality finishes efficiently and consistently.

Aluminum is favored in numerous industries due to its lightweight, corrosion-resistant, and malleable characteristics. However, these advantages also necessitate a careful approach in processing to enhance its visual appeal and functional performance. A polished aluminum tube not only becomes more visually appealing but also exhibits a smoother surface, which can improve its mechanical properties and extend its lifespan.

Aluminum tube polishing machines come equipped with advanced technologies designed to streamline the polishing process. These machines work by using abrasive materials and compounds that effectively remove imperfections from the surface of aluminum tubes. The polishing process involves four major steps cleaning, pre-polishing, polishing, and finishing. Each step is crucial to ensure a flawless result.

Initially, cleaning is essential to remove dirt, dust, and grease from the surface of the aluminum tube. This preparation phase sets the foundation for the subsequent polishing steps. After cleaning, the pre-polishing phase utilizes coarser abrasives to eliminate deeper scratches and imperfections, ensuring that the surface is ready for the finer polishing required to achieve a high-gloss finish.

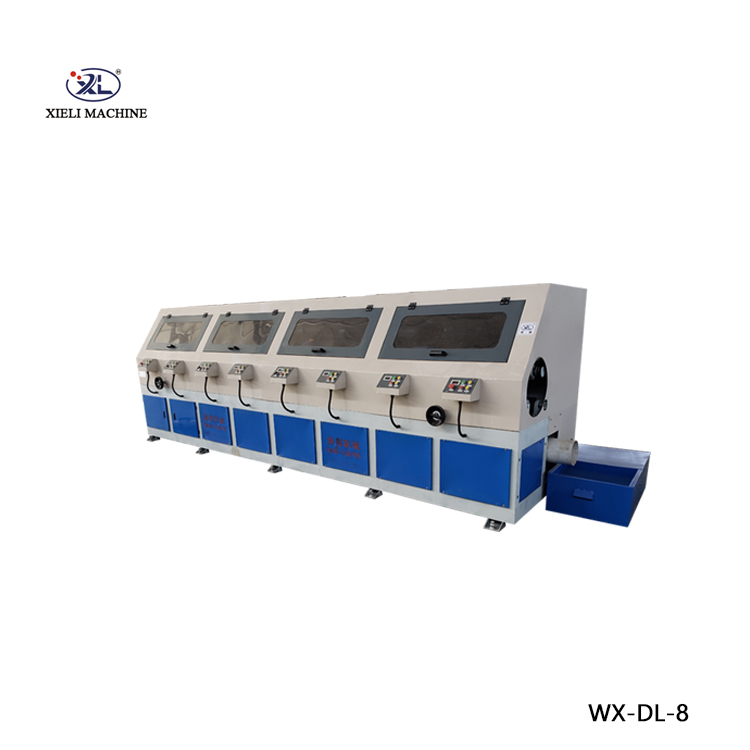

aluminum tube polishing machine product

The primary polishing process involves the use of softer abrasives and polishing compounds, which gently deliver a smooth and shiny surface. This step is critical as it significantly enhances the visual appeal of the aluminum tubes, making them suitable for applications where aesthetics are vital, such as architectural designs or consumer goods. Finally, the finishing step often employs a specialized treatment such as anodizing or coating, which not only enhances the appearance but also increases the corrosion resistance of the aluminum.

Investing in a high-quality aluminum tube polishing machine can yield significant benefits for manufacturing operations. These machines provide consistency, efficiency, and high-quality finishes that manual polishing may struggle to achieve. By automating the polishing process, manufacturers can reduce labor costs, minimize human error, and increase production output. Moreover, the precision offered by modern polishing machines allows manufacturers to meet stringent industry standards, making their products more competitive in the market.

In addition to efficiency and consistency, aluminum tube polishing machines also offer flexibility. Many of these machines are designed to handle various sizes and shapes of aluminum tubes, accommodating the diverse needs of different industries. This adaptability ensures that manufacturers can cater to a broader range of applications, from small-run specialty items to large-scale productions.

Overall, the proper machinery for polishing aluminum tubes can be a game-changer for manufacturers seeking to enhance their product offerings. By investing in technology that streamlines the polishing process, organizations can improve their operational efficiency, product quality, and ultimately, customer satisfaction. The importance of aluminum tube polishing machines cannot be overstated; they are critical tools in the journey towards perfection in metal fabrication. As industries continue to evolve, the demand for high-quality, polished aluminum products will only increase, making these machines an invaluable asset for any manufacturing enterprise.