The Role of Aluminum Tube Polishing Machine Manufacturers in the Metal Finishing Industry

In the constantly evolving field of metal finishing, aluminum tube polishing machines play a crucial role in enhancing the aesthetic and functional qualities of aluminum tubes. As the demand for high-quality finished aluminum products increases across various industries, the significance of manufacturers specializing in these polishing machines becomes increasingly apparent. This article delves into the importance of aluminum tube polishing machine manufacturers and their contribution to the industry.

Understanding the Polishing Process

Polishing is a vital process in the manufacturing of aluminum tubes as it improves surface finish, enhances corrosion resistance, and prepares the tubes for further processing or use. Aluminum tubes are widely used in industries ranging from aerospace to automotive, construction, and consumer products. The polished finish not only elevates appearance but also plays a significant role in the performance of the products made from these tubes.

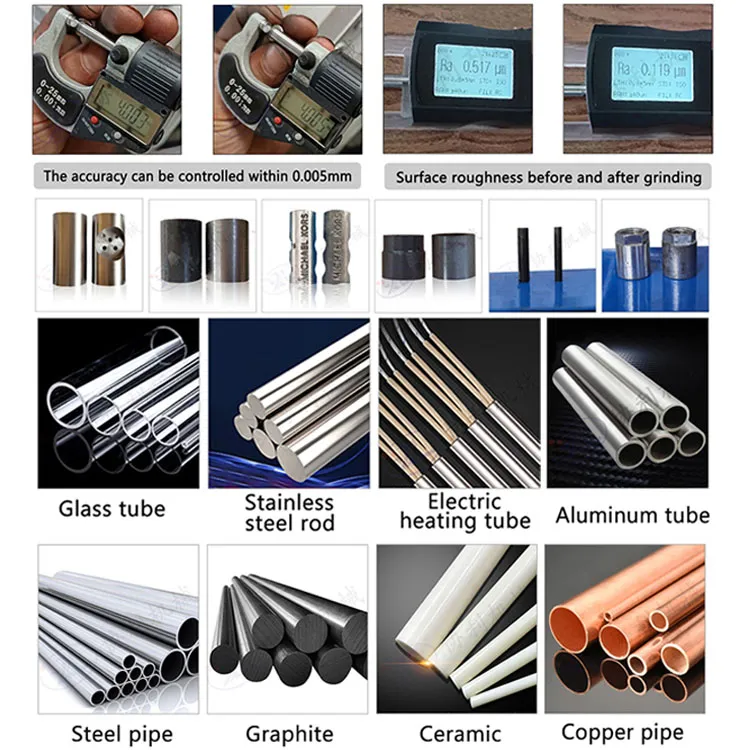

Aluminum tube polishing machines utilize a combination of technologies, including mechanical polishing, chemical polishing, and electrochemical processes, to achieve a desired finish. The right machine can significantly enhance productivity while minimizing material waste and energy consumption. Therefore, it is imperative to choose a reliable manufacturer that provides innovative and efficient polishing solutions.

Key Features of High-Quality Polishing Machines

Manufacturers of aluminum tube polishing machines offer a variety of models to cater to different production needs. Key features to look for include

1. Versatility The machine should accommodate various tube sizes and profiles, allowing manufacturers to handle diverse projects without investing in multiple machines.

3. Precision A high-quality polishing machine provides fine control over the polishing process, ensuring an even finish without damaging the aluminum substrate.

aluminum tube polishing machine manufacturer

4. Durability The machines should be robust enough to withstand continuous operation in high-demand environments and made from materials that resist corrosion and wear.

5. Ease of Use User-friendly interfaces and easy maintenance protocols are essential, as they reduce downtime and training requirements for operators.

The Importance of Choosing the Right Manufacturer

Selecting the right aluminum tube polishing machine manufacturer can have profound implications on the quality of the final product. A reputable manufacturer will not only provide high-quality machinery but also offer excellent after-sales support, including installation, training, and maintenance services. This support ensures that manufacturers can consistently achieve the desired finish on their aluminum products.

Furthermore, a manufacturer that invests in research and development is more likely to integrate the latest advancements in polishing technology, which can lead to improved efficiency and sustainability.

Industry Trends and Future Outlook

As industries increasingly focus on sustainability, manufacturers are innovating to reduce the environmental impact of their machines. This includes developing technology that minimizes energy consumption and enhances the recyclability of polished aluminum products. The trend towards automation and smart manufacturing is also set to shape the future of aluminum tube polishing machines, offering greater efficiencies and reducing the need for skilled labor.

Conclusion

Aluminum tube polishing machine manufacturers play a pivotal role in the metal finishing industry. Their continuous innovation and commitment to quality not only enhance the performance and aesthetic qualities of aluminum products but also contribute to the overall efficiency and sustainability of the manufacturing process. As the demand for polished aluminum tubes continues to rise, the partnership between manufacturers and polishing machine producers will be key to meeting market requirements effectively.