Understanding Aluminium Tube Polishing Machines Quotes and Insights

Aluminium is a versatile and widely-used metal, favored for its lightweight and corrosion-resistant properties. Industries like automotive, aerospace, and manufacturing rely heavily on aluminium components. However, to maintain the aesthetic appeal and functional performance of aluminium products, polishing is crucial. This is where aluminium tube polishing machines come into play. In this article, we'll explore the significance of these machines, factors influencing their pricing, and the broad spectrum of quotes available in the market.

The Importance of Aluminium Tube Polishing

Polishing aluminium tubes is essential for multiple reasons. It not only enhances the visual appearance of the products but also improves their reflectivity and overall surface finish. A smooth surface can reduce friction, enhance resistance to corrosion, and ensure better bonding in applications like powder coating or anodizing. Particularly in sectors where high-quality finish is requisite, such as the automotive and aerospace industries, the demand for efficient polishing solutions is high.

Key Features of Aluminium Tube Polishing Machines

When considering purchasing a polishing machine, it is important to understand the core features that make them effective

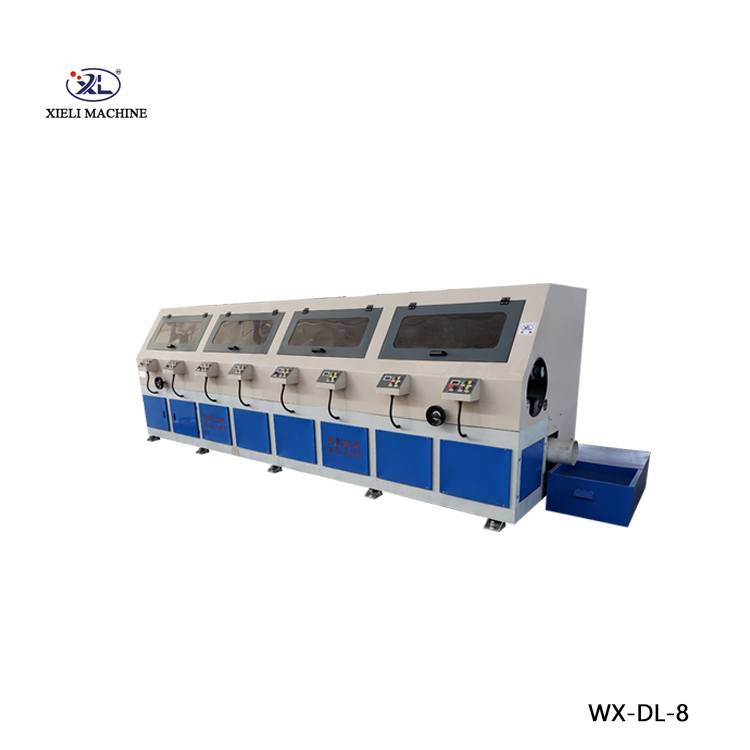

1. Automation Many modern machines offer automated processes that enhance productivity and reduce the likelihood of human error. 2. Versatility Machines that can accommodate a range of tube sizes and shapes are increasingly popular, allowing for greater efficiency in production lines. 3. Efficiency Advanced polishing machines are designed to minimize material waste while maximizing output, thereby optimizing cost-effectiveness. 4. Precision High-quality machines provide consistent results with minimal variance, ensuring that each piece meets the required standards.

5. Easy Maintenance User-friendly designs that allow for easy cleaning and maintenance can significantly reduce downtime and operational costs.

Factors Influencing Pricing

The cost of aluminium tube polishing machines can vary widely, influenced by several factors

1. Machine Type There are different types of polishing machines available, including manual, semi-automatic, and fully automatic systems. Generally, fully automatic machines tend to be priced higher due to their advanced features.

aluminium tube polishing machine quotes

3. Brand Reputation Established and reputable manufacturers often charge premium prices due to their reliability and the after-sale support they provide.

4. Customization Custom-built machinery tailored to specific manufacturing needs may result in higher costs, but it can lead to improved productivity and efficiency in the long run.

5. Technological Innovations The implementation of the latest technology, such as IoT or AI in controlling polishing processes, can significantly affect pricing.

Exploring Quotes

When seeking quotations for aluminium tube polishing machines, it is advisable to reach out to multiple suppliers. Here are some tips to consider

- Detailed Requirements Before requesting quotes, clearly define your requirements in terms of tube dimensions, quantity, and desired finish. This will help suppliers provide more accurate quotes. - Negotiate Don’t hesitate to negotiate on prices. Suppliers often have some flexibility, especially for bulk orders or long-term partnerships.

- Evaluate Total Cost of Ownership Beyond the initial purchase price, consider factors like operational costs, maintenance, and potential downtime. A cheaper machine might lead to higher expenses in the long run.

- Seek Recommendations Consult industry peers and online forums to find reliable suppliers and gather insights on their experiences with different machines.

Conclusion

Aluminium tube polishing machines play a critical role in ensuring the quality and durability of aluminium products. By understanding the features, pricing factors, and the importance of obtaining multiple quotes, businesses can make informed decisions that enhance their production capabilities. As technology continues to evolve, investing in advanced polishing machines is likely to provide substantial returns in terms of efficiency and product quality, ultimately driving success in a competitive market.