The Best Pipe End Grinding Machines A Comprehensive Overview

In the world of metalworking and fabrication, the finishing process is just as critical as the initial cutting or shaping of materials. One essential aspect of this process is the end grinding of pipes. Pipe end grinding machines have become invaluable tools in industries ranging from construction to automotive, providing efficient, high-quality finishes to pipe ends. This article explores the features, benefits, and considerations when choosing the best pipe end grinding machine.

Understanding Pipe End Grinding

Pipe end grinding involves the smoothing and shaping of the ends of pipes to ensure proper fit and joint integrity. This process is crucial for applications like welding, where precisely finished ends can lead to stronger and leak-proof connections. Poorly finished pipe ends can result in issues that affect the quality and safety of engineered systems.

Key Features of a Quality Pipe End Grinding Machine

When searching for the best pipe end grinding machine, several features should be at the forefront of your decision-making process

1. Versatility Many grinding machines offer adjustable clamps and fixtures that can accommodate different pipe diameters and materials, making them suitable for various applications.

2. Power and Speed Machines equipped with powerful motors and variable speed settings allow users to optimize grinding performance for specific tasks. Higher speed options can lead to faster production rates without compromising quality.

3. Precision A quality pipe end grinding machine provides precision in cutting and grinding, ensuring that the ends are uniformly shaped and smooth. This level of accuracy is vital for achieving optimal welding conditions.

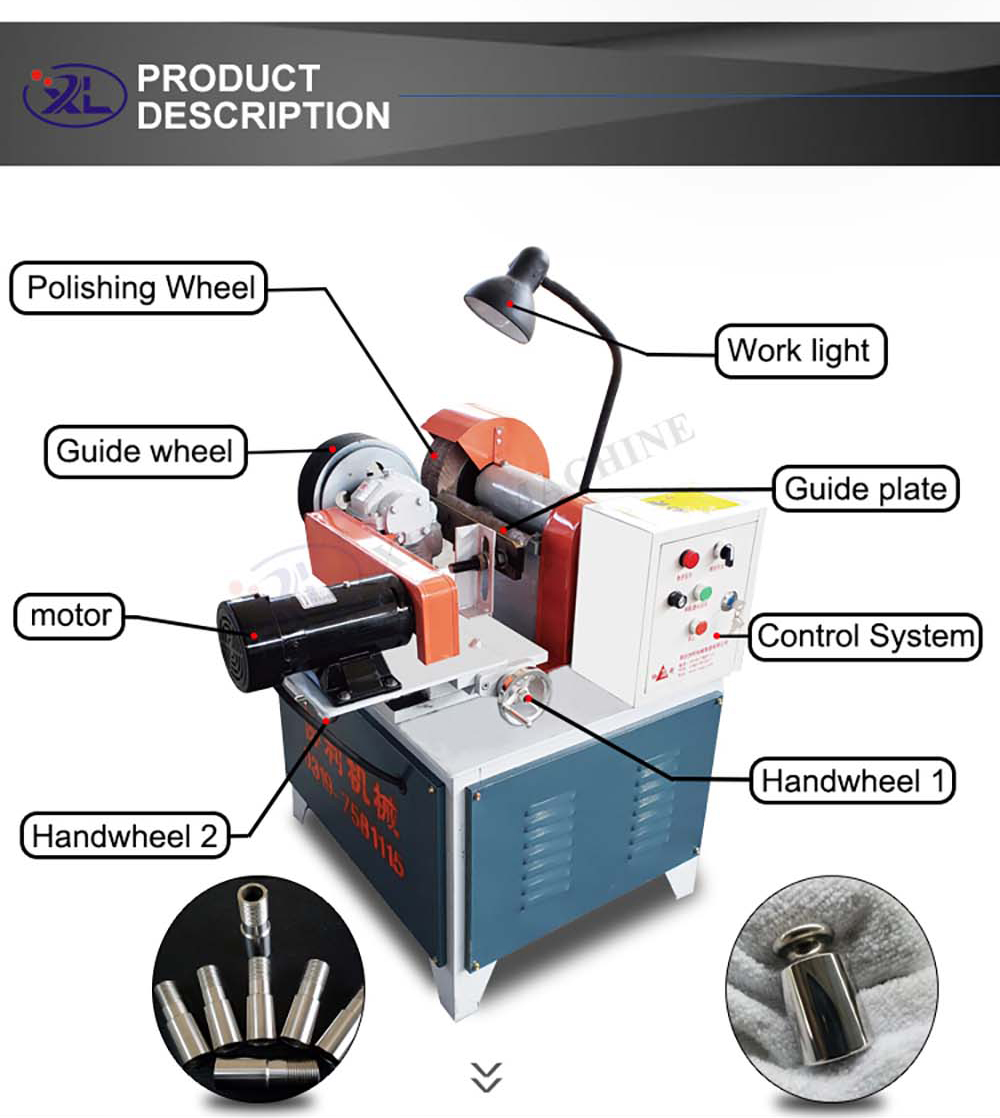

best pipe end grinding machine

5. Durability and Build Quality The best machines are typically constructed from robust materials, which ensures longevity and performance even in high-demand environments. Investment in a durable machine can save costs in the long run.

6. Safety Features Safety is paramount in any industrial setting. Look for machines equipped with protective guards, emergency stop buttons, and safety interlocks to enhance operator safety during use.

Benefits of Using a Pipe End Grinding Machine

Utilizing a dedicated pipe end grinding machine presents numerous advantages

- Increased Efficiency These machines are designed specifically for grinding pipe ends, resulting in quicker completion times compared to manual grinding techniques.

- Enhanced Quality The precision offered by modern grinding machines yields a much higher quality finish, which is critical for industrial applications where fit and join integrity are key.

- Reduced Labor Costs Automation of the grinding process can significantly minimize labor requirements, allowing skilled workers to focus on more complex tasks rather than repetitive grinding.

- Consistency Automated machines provide consistent results, ensuring that every piece processed meets the required specifications.

Conclusion

Choosing the best pipe end grinding machine is a strategic decision that can profoundly impact efficiency, quality, and safety in metalworking operations. By carefully considering features such as versatility, power, precision, and safety, businesses can select a machine that will meet their specific needs. Investing in high-quality grinding equipment not only improves the finishing process of pipe ends but also enhances overall productivity and product integrity in various industrial applications. Whether you operate in manufacturing, construction, or automotive, the right pipe end grinding machine can make all the difference in achieving superior outcomes.