The ODM Retrofit Servo Centerless Grinder Revolutionizing Precision Grinding

In the realm of manufacturing, precision is paramount, particularly when it comes to grinding processes. Centerless grinding, known for its efficiency in producing cylindrical parts, has seen significant innovations over the years. One such innovation is the ODM retrofit servo centerless grinder, a game-changer that not only enhances operational efficiency but also improves the quality of the end products.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from the outside diameter of a workpiece. Unlike traditional grinding machines, centerless grinders do not require the workpiece to be fixed in place with a chuck but are instead supported between a grinding wheel and a regulating wheel. This design allows for continuous production, making it ideal for high-volume manufacturing of cylindrical components.

The Need for Retrofitting

As technology advances, the need for updated machinery in manufacturing plants becomes apparent. Many existing centerless grinders are equipped with older technologies that limit their performance, accuracy, and versatility. Retrofitting these machines with modern servo technology is a cost-effective solution that can extend the life of the equipment while significantly enhancing its capabilities.

Benefits of the ODM Retrofit Servo Centerless Grinder

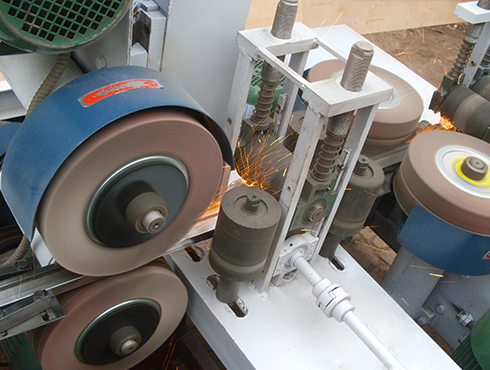

odm retrofit servo centerless grinder

1. Enhanced Precision The ODM retrofit system introduces precision servo motors that control the movement of the grinding and regulating wheels with exceptional accuracy. This results in a more refined grinding process, leading to superior dimensional tolerances and surface finishes.

2. Improved Efficiency Traditional centerless grinders may struggle with maintaining consistent feed rates. The ODM retrofit addresses this issue by implementing a closed-loop control system, enabling real-time adjustments based on feedback from the grinding process. This ensures optimal grinding speeds and reduced cycle times.

3. Flexibility and Versatility Modern manufacturing often requires the ability to adapt to different production needs. The ODM retrofit allows operators to easily switch between various workpiece sizes and materials without the need for extensive reconfiguration. This versatility is essential in today’s dynamic market.

4. Increased Automation The incorporation of servo technology allows for greater automation in the grinding process. With programmable settings and automated adjustments, operators can achieve a higher level of consistency, reduce human error, and allocate human resources to more strategic tasks.

5. Cost-Effectiveness Investing in a completely new grinding machine can be a substantial financial burden. Retrofitting existing machines with ODM technology provides a cost-effective alternative, offering many of the benefits of new equipment without the significant capital expenditure.

Conclusion

The ODM retrofit servo centerless grinder represents a significant advancement in grinding technology, offering manufacturers the tools they need to stay competitive in a rapidly evolving industry. As companies strive to improve productivity and product quality, retrofitting existing machines with modern servo controls emerges as a viable solution. With benefits ranging from enhanced precision and efficiency to increased automation and flexibility, it is no wonder that more manufacturers are turning to ODM retrofit solutions for their centerless grinding needs. Upgrading to this technology not only modernizes equipment but also provides a path toward a more streamlined and effective manufacturing process.