In the realm of industrial manufacturing, precision and efficiency are paramount, particularly when dealing with components that require meticulous shaping, polishing, or finishing.

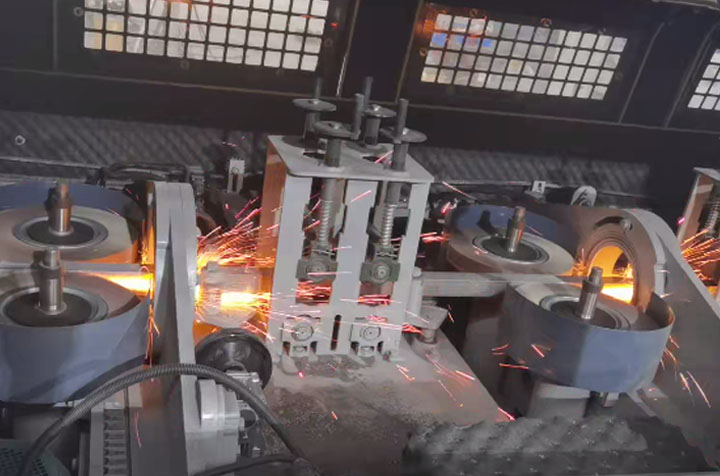

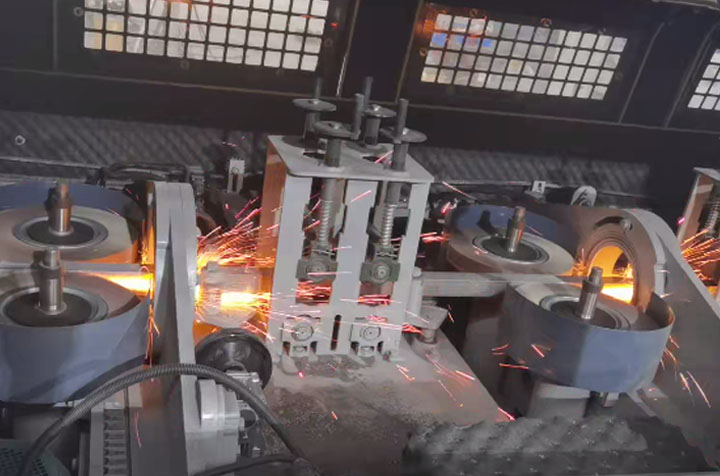

This is where palmary centerless grinding machines come into play. Known for their unparalleled precision and capability to handle a variety of materials, these machines are indispensable to many manufacturing processes globally. When searching for reliable suppliers of palmary centerless grinding machines, several factors should be considered to ensure product and service excellence.

Centerless grinding is a unique machining process that helps achieve a high level of accuracy and surface finish by removing material from the external surface of a workpiece. This is achieved without using a spindle or fixture to secure the workpiece. Finding the right supplier, however, is crucial to harnessing these capabilities effectively.

A supplier offering palmary centerless grinding machines should possess a wealth of experience and technical expertise within the industry. The seasoned suppliers not only provide robust and efficient machines but also offer insight into optimizing machine usage for specific applications. Thus, their experience ensures that they can address complex requirements and provide customized solutions, contributing to improved operational efficiency and product quality.

Trustworthiness and authoritativeness are equally critical in evaluating suppliers. It's important to ascertain that a supplier is not only knowledgeable, but also recognized and respected in the industry. One way to gauge this is by checking for industry accolades and certifications that highlight their compliance with international standards. Testimonials and case studies can also provide insight into the supplier's reputation and the reliability of their machines in various operational settings.

Moreover, interconnectedness and the ability to provide exceptional support are essential attributes of a reputable palmary centerless grinding machine supplier. Comprehensive after-sales support, including training, maintenance, and quick response to service inquiries, demonstrates a supplier's commitment to customer satisfaction and long-term partnership. This support system plays a crucial role in minimizing downtime and ensuring machine longevity.

palmary centerless grinding machine suppliers

The adaptability of equipment supplied is another factor that cannot be overlooked. The palmary centerless grinder should be versatile, with the capacity to handle diverse materials and a range of sizes to meet evolving production needs. High-precision adjustable features enhance this adaptability, allowing for consistent product quality and process efficiency.

Furthermore, innovative suppliers at the forefront of the industry are continuously improving their product offerings. They invest in research and development to incorporate the latest technology and advancements in their machines. For clients looking to maximize productivity while minimizing labor costs and production errors, these innovations are invaluable.

However, not all suppliers are created equal. In-depth research is necessary when selecting a supplier to ensure alignment with operational goals and capabilities. In this regard, a transparent and open line of communication with potential suppliers can provide significant insights into their processes and values. Understanding whether a supplier can accommodate your specific manufacturing needs and expectations is a part of strategic procurement.

From initial consultation through to full-scale implementation, suppliers should guide their clients on machine integration within production setups. The feedback loop between the supplier and the customer generates vital data that can refine operations and boost productivity.

In conclusion, finding the ideal palmary centerless grinding machine suppliers entails looking beyond the machine itself. It involves evaluating the supplier's experience, expertise, commitment to quality, and customer support systems. Reputable suppliers not only deliver advanced, reliable equipment but also become valued partners in manufacturing success through continuous support and innovation. Making an informed choice can significantly enhance manufacturing processes, product quality, and, consequently, business competitiveness in the market.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.