The Future of Manufacturing Custom Centerless Grinder Automation

In the competitive arena of manufacturing, efficiency and precision are paramount. One of the key innovations that have emerged in recent years is the automation of centerless grinding processes. Centerless grinders are essential machines used for producing high-volume components with tight tolerances, and automating these systems can significantly enhance their productivity and accuracy.

Centerless grinding is characterized by the ability to grind parts without the need for a fixture or support, making it ideal for cylindrical components. The automation of this process involves integrating advanced technologies that streamline operations, reduce human error, and maximize throughput. Custom centerless grinder automation takes this a step further by tailoring solutions to meet specific manufacturing needs, thereby offering flexibility and adaptability in production.

The incorporation of robotics into the centerless grinding operation is one of the most significant advancements in this field. Automated systems can be programmed to perform various tasks such as loading and unloading parts, measuring dimensions, and making necessary adjustments in real-time. This reduces the reliance on manual labor, minimizes the risk of injury, and allows skilled workers to focus on oversight and quality control rather than repetitive tasks.

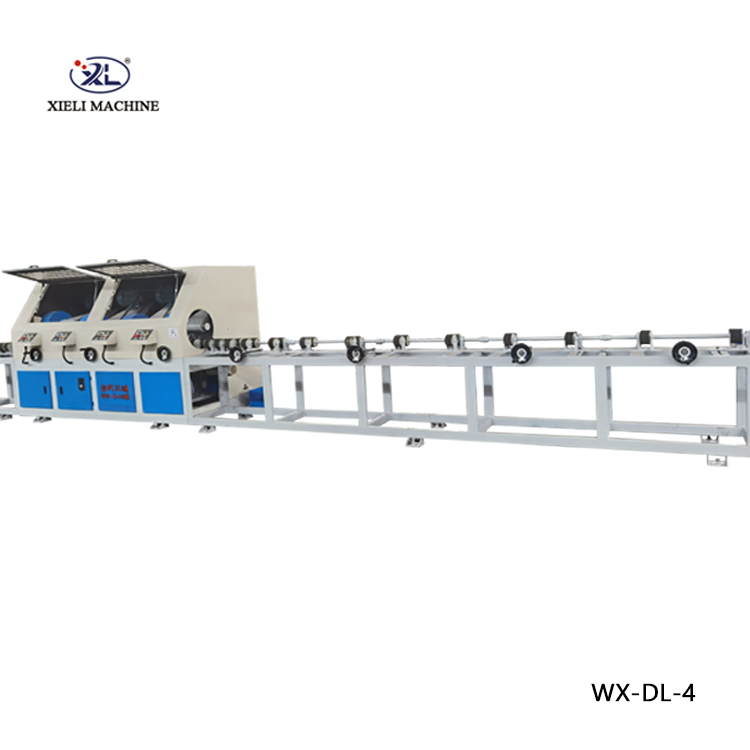

custom centerless grinder automation

Moreover, custom automation solutions can be designed to fit unique production workflows. For instance, manufacturers can select from a range of robotic arms, conveyor systems, and software interfaces that can be customized based on the size and shape of the parts being produced. This flexibility enables companies to adapt quickly to changing market demands without needing to overhaul entire production lines.

Implementing automated centerless grinding operations also leads to improved consistency in product quality. With advanced sensors and machine learning algorithms, automated systems can continuously monitor key parameters such as speed, temperature, and material feed rates. This data-driven approach allows for real-time adjustments, ensuring that each part meets the required specifications, thereby reducing waste and rework.

Furthermore, the integration of automation in centerless grinding can significantly enhance production rates. Automated systems can operate around the clock, with minimal downtime for maintenance or changeover, leading to increased output and reduced lead times. This is particularly advantageous in industries where demand for precision components is high, such as aerospace, automotive, and medical device manufacturing.

In conclusion, custom centerless grinder automation represents a significant leap forward in manufacturing efficiency and quality. By incorporating robotic technology, real-time monitoring, and tailored solutions, manufacturers can boost productivity, minimize errors, and enhance the overall quality of their products. As industries continue to evolve, embracing such automation innovations will be essential for staying competitive in a fast-paced market. With ongoing advancements in technology, the future of centerless grinding promises to be more efficient, precise, and adaptable than ever before.