Enhancing Surface Integrity and Performance in Industrial Pipes

In diverse industrial sectors, the surface quality of steel pipes is paramount for operational efficiency, longevity, and safety. From petrochemical pipelines enduring extreme pressures and corrosive environments to architectural structures demanding aesthetic appeal, the finish of a steel pipe directly impacts its performance. This article delves into the critical role of the steel pipe polishing machine, a specialized industrial solution designed to achieve superior surface finishes, remove defects, and enhance the functional properties of steel tubing. We explore its manufacturing intricacies, technological advantages, broad application spectrum, and the benefits it offers to modern industries seeking optimized material performance.

Detailed Process Flow: Manufacturing the Polishing Machine

The production of a high-performance steel pipe polishing machine involves a sophisticated multi-stage manufacturing process, ensuring precision, durability, and operational excellence. Each component is meticulously crafted to withstand rigorous industrial demands, adhering to stringent quality control protocols.

Materials and Core Components

- Structural Frame: Constructed from heavy-duty, high-tensile steel alloys (e.g., Q345B, A36 equivalent) for maximum rigidity and vibration dampening. This ensures machine stability during high-speed operations.

- Polishing Heads: Often made from wear-resistant materials such as hardened tool steel or specialized composites, designed for optimal abrasive contact and longevity. The choice of abrasive (e.g., flap wheels, abrasive belts, sisal wheels) depends on the desired finish and material.

- Drive Systems: Incorporate high-efficiency motors (IE3 or IE4 rated for energy saving) and precision gearboxes or belt drives, ensuring consistent rotational speed and torque. Variable Frequency Drives (VFDs) are commonly integrated for precise speed control.

- Conveyor/Feeding System: Utilizes hardened steel rollers or specialized rubberized belts, precision-machined for smooth, uniform pipe feeding, minimizing pipe deformation or slippage.

- Coolant/Lubrication System (for Wet Polishing): Features corrosion-resistant pumps, filters, and reservoirs, critical for dissipating heat, flushing debris, and achieving superior surface finishes while preventing rust.

Manufacturing Processes

- CAD/CAM Design & Simulation: Initial design using advanced CAD software, followed by FEM (Finite Element Method) analysis to optimize structural integrity and identify potential stress points.

- Material Preparation & Cutting: Raw steel plates and profiles are precisely cut using CNC laser or plasma cutting machines to achieve exact dimensions.

- CNC Machining & Forging: Critical components, such as shafts, gears, and polishing head housings, undergo CNC machining for high precision. Forged components are utilized where extreme strength and wear resistance are required, such as in heavy-duty rollers.

- Welding & Fabrication: Structural frame components are welded using robotic or skilled manual MIG/TIG welding processes, followed by stress relieving to prevent distortion.

- Surface Treatment & Painting: Components are sandblasted, primed, and coated with industrial-grade corrosion-resistant paints (e.g., epoxy-based) for protection against harsh operating environments.

- Assembly & Integration: Mechanical, electrical, and pneumatic systems are assembled, ensuring correct alignment and functionality. Precision bearings, seals, and lubrication systems are installed.

- Electrical & Control System Integration: PLC (Programmable Logic Controller) systems, HMI (Human-Machine Interface) touchscreens, sensors, and safety interlocks are wired and programmed for automated operation and fault diagnostics.

Precision engineering of a steel pipe polishing machine.

Testing Standards and Quality Assurance

Every machine undergoes rigorous testing to comply with international standards. This includes:

- ISO 9001: For quality management systems throughout the manufacturing process.

- CE Marking: Compliance with European health, safety, and environmental protection standards.

- ANSI/ASTM: Where applicable for material specifications and testing procedures.

- Operational Performance Tests: Load testing, continuous operation cycles, vibration analysis, noise level measurement, and verification of surface roughness (Ra values) against specified targets.

The typical service life of a well-maintained steel pipe polish machine is 15-20 years, a testament to robust construction and quality components.

Industry Trends in Steel Pipe Finishing

The market for steel pipe finishing is dynamic, driven by evolving material science, environmental regulations, and demand for higher performance. Key trends include:

- Automation and Industry 4.0 Integration: Increased adoption of automated feeding, robotic polishing arms, and real-time monitoring systems enabled by IoT, optimizing throughput and minimizing human intervention.

- Sustainability and Energy Efficiency: Focus on machines with lower power consumption (e.g., through high-efficiency motors, intelligent control systems) and improved waste management, including advanced coolant filtration and recycling.

- Precision Finishing: Growing demand for extremely low surface roughness (e.g., Ra

- Versatility in Materials and Shapes: Machines designed to handle a wider range of steel alloys (stainless steel, duplex, superalloys) and various pipe shapes (round, square, rectangular, oval).

- Enhanced Corrosion Resistance: For industries like offshore oil & gas and chemical processing, a perfectly polished surface significantly enhances the inherent corrosion resistance of the material by removing surface imperfections where corrosion can initiate.

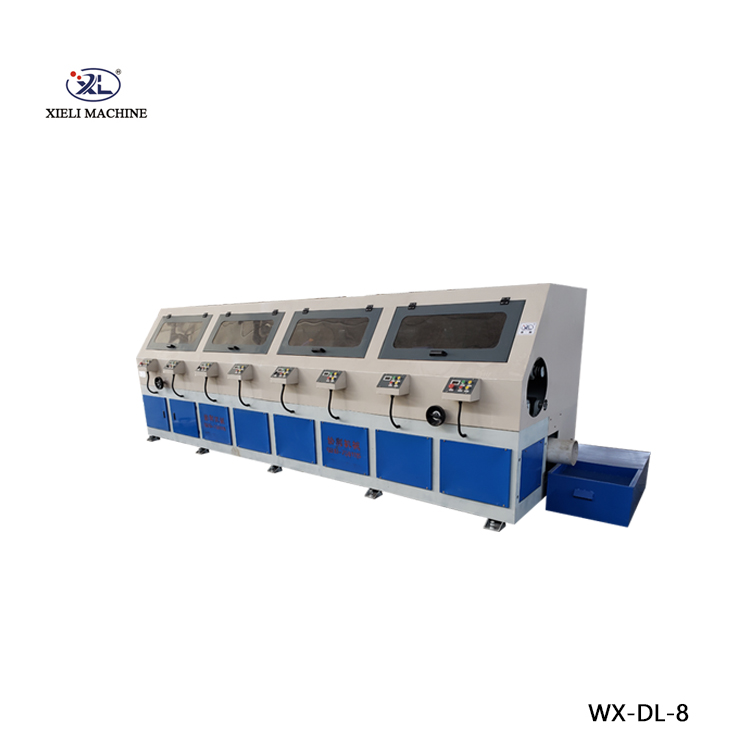

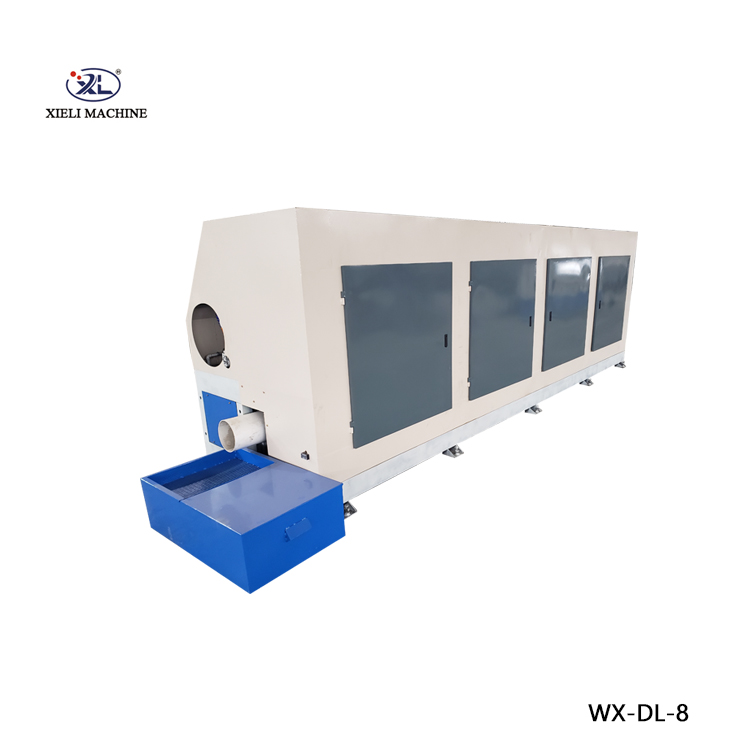

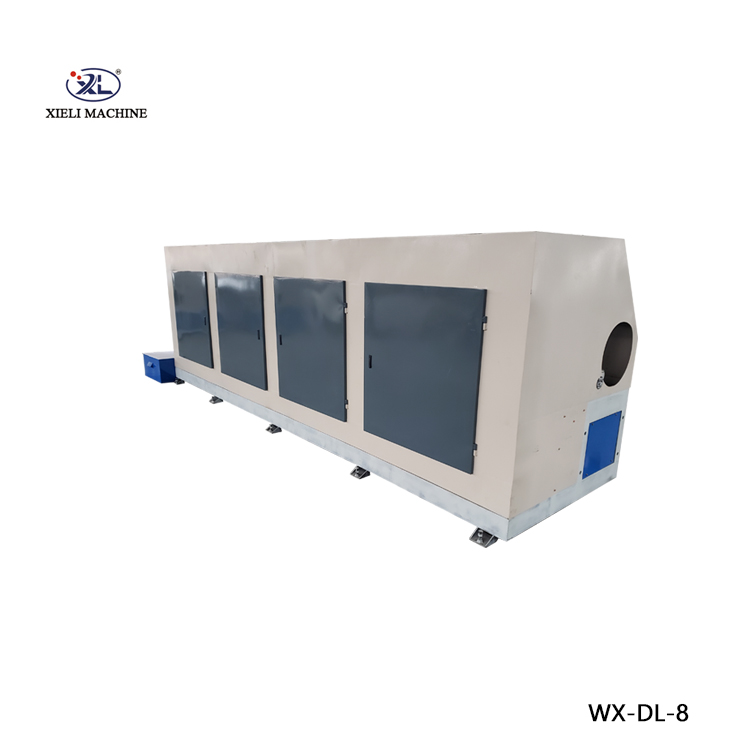

Technical Specifications: New Wet Steel Pipe Rust Polishing Machine

The "New wet steel pipe rust polishing machine price" offers an optimal balance of performance, efficiency, and robustness. Below are typical specifications for a high-grade steel pipe polishing machine engineered for superior results.

A detailed view of the steel pipe polishing machine's wet polishing mechanism.

| Parameter | Specification | Description |

|---|---|---|

| Applicable Pipe Diameter | Ø10mm - Ø200mm (configurable) | Wide range suitable for various industrial pipes. |

| Polishing Heads Quantity | 4 to 12 stations (modular design) | Allows multi-stage polishing from coarse to fine finish. |

| Main Motor Power | 4 kW - 22 kW per head (adjustable) | High torque for efficient material removal and consistent finish. |

| Feeding Speed | 0.5 - 10 m/min (variable speed drive) | Optimized for various pipe materials and desired surface roughness. |

| Surface Roughness Achieved | Ra 0.2 µm - Ra 1.6 µm (typical) | Capable of mirror-like finish or functional matte. |

| Coolant System Capacity | 200L - 1000L (integrated filtration) | Ensures wet polishing efficiency, heat dissipation, and debris removal. |

| Power Supply | 3-Phase, 380V/50Hz (customizable) | Standard industrial power requirements. |

| Control System | PLC with HMI Touchscreen | Intuitive operation, fault diagnostics, recipe management. |

| Machine Dimensions (L x W x H) | Varies by configuration | Designed for industrial facility integration. |

Application Scenarios and Target Industries

The versatility of a high-quality steel pipe polishing machine makes it indispensable across numerous industries where surface integrity and visual appeal of tubular components are crucial.

- Petrochemical and Oil & Gas: For pipelines transporting corrosive fluids or gases, a smooth internal and external surface minimizes friction loss, prevents scale buildup, and enhances corrosion resistance, extending the asset's lifespan and ensuring safety. Typical pipes include stainless steel and carbon steel for transport and processing.

- Metallurgy and Steel Mills: Post-welding or drawing, pipes often require descaling, rust removal, and surface conditioning to prepare for further processing (e.g., coating, bending) or direct use. Polishing ensures compliance with industry standards for structural integrity and appearance.

- Water Supply & Drainage: Polished pipes reduce frictional losses in water flow, minimize accumulation of biological films (biofouling), and improve overall hydraulic efficiency in municipal and industrial water systems.

- Construction and Architecture: For exposed structural elements, handrails, balustrades, and decorative applications, a mirror-polished or satin finish is critical for aesthetic appeal and resistance to environmental degradation.

- Food & Beverage and Pharmaceutical: High-purity applications demand ultra-smooth internal surfaces (often Ra

- Automotive and Aerospace: Exhaust systems, hydraulic lines, and structural components benefit from polished surfaces for improved flow dynamics, corrosion resistance, and fatigue life.

Steel pipes undergoing precise finishing for various industrial applications.

Advantages in Typical Application Scenarios:

- Energy Saving: For fluid transport, a smoother internal surface reduces fluid friction, leading to lower pumping energy requirements.

- Enhanced Corrosion Resistance: Removal of surface imperfections (e.g., weld seams, minor rust, scratches) eliminates initiation points for pitting corrosion and crevice corrosion.

- Improved Flow Dynamics: Critical for high-purity gas lines or viscous fluid transport, minimizing turbulence and pressure drop.

- Aesthetic Value: Essential for architectural and consumer-facing applications, providing a visually appealing, uniform finish.

- Extended Service Life: By mitigating common failure mechanisms like corrosion and fatigue, polished pipes last longer, reducing maintenance and replacement costs.

Technical Advantages of Advanced Steel Pipe Polishing Machines

Modern steel pipe polishing machine designs incorporate several key technical advantages that set them apart, ensuring superior performance and operational benefits.

- Multi-Stage Polishing Capability: Machines are typically equipped with multiple independent polishing heads (e.g., 4, 6, 8, 10, 12 stations), allowing for progressive abrasion from coarse grinding to mirror finishing in a single pass. This ensures optimal material removal and surface refinement.

- Automated Feeding and Ejection Systems: Integrated PLC-controlled conveyor systems ensure consistent pipe feeding, minimizing manual handling and optimizing throughput. This also reduces labor costs and enhances operator safety.

- Variable Speed Control (VFD): Independent Variable Frequency Drives for each polishing head and the feeding system allow precise control over rotational speed and feed rate. This adaptability is crucial for processing different materials, diameters, and achieving specific surface roughness (Ra) targets.

- Wet Polishing Technology: Utilizes a circulating coolant system that continuously flushes debris, dissipates heat generated during abrasion, and prevents spark formation. This results in a cleaner, smoother finish, prolongs abrasive life, and prevents discoloration or warping of the pipe. It is particularly effective for rust removal and preventing re-oxidation.

- Robust and Vibration-Damped Construction: Heavy-duty fabricated frames and precision-machined components minimize vibration during operation, which is critical for achieving consistent, high-quality finishes and extending machine longevity.

- User-Friendly HMI and Diagnostics: Modern machines feature intuitive Human-Machine Interfaces (HMI) for easy parameter setting, recipe management, and real-time operational monitoring. Integrated diagnostic systems alert operators to potential issues, facilitating proactive maintenance.

- Quick Changeover Design: Features like quick-release abrasive holders and adjustable roller systems facilitate rapid setup changes for different pipe diameters and polishing requirements, maximizing machine uptime.

Vendor Comparison: Choosing the Right Steel Pipe Polishing Solution

Selecting the optimal steel pipe polishing machine requires a thorough evaluation of vendor capabilities beyond just price. Here's a comparison framework to guide decision-makers:

| Feature/Criterion | Specialized Manufacturer (e.g., Xielizz) | Generalist Supplier |

|---|---|---|

| Product Specialization | Deep expertise in pipe/tube polishing machines, highly optimized designs. | Broader product range; polishing machines may be a secondary offering. |

| Customization & R&D | Strong R&D, offering tailored solutions for unique pipe sizes, materials, and finish requirements. | Limited customization options; often standard off-the-shelf models. |

| Technology & Innovation | Incorporates latest automation, energy efficiency, and precision polishing technologies. | May use older or less efficient technology; slower to adopt innovations. |

| Build Quality & Components | Utilizes premium, durable components (e.g., Siemens, Schneider, SKF) for extended service life. | May use lower-cost components to reduce manufacturing expense, impacting longevity. |

| After-Sales Support & Spares | Dedicated technical support, readily available spare parts, comprehensive service network. | Support may be less specialized or slower; spare parts availability can be an issue. |

| Price vs. Value | Higher initial investment, but superior ROI due to reliability, efficiency, and longevity. | Lower initial price, but potentially higher long-term operating and maintenance costs. |

Choosing a specialized manufacturer ensures you receive a machine optimally designed for your specific pipe polishing needs, backed by expert support and a commitment to innovation, leading to better long-term performance and lower total cost of ownership.

Customized Solutions for Unique Polishing Challenges

Recognizing that industrial requirements are rarely one-size-fits-all, leading manufacturers offer highly customizable steel pipe polishing machine solutions. This ensures that the equipment perfectly integrates into existing production lines and meets precise operational specifications.

Customization options often include:

- Pipe Diameter and Length Range: Tailoring machine capacity to accommodate exceptionally large or small diameter pipes, or very long pipe sections.

- Material Specificity: Adjustments for exotic alloys (e.g., Inconel, Titanium) requiring different abrasive types, polishing speeds, and cooling regimes.

- Desired Surface Finish (Ra Value): Configuring the number of polishing stations and abrasive sequences to achieve ultra-fine finishes for sensitive applications (e.g., medical, semiconductor).

- Automation Level: From semi-automatic systems to fully automated lines with robotic loading/unloading and integration with upstream/downstream processes.

- Environmental Controls: Specialized dust collection, coolant management, and noise reduction measures for specific factory environments or regulatory compliance.

- Safety Features: Enhanced guarding, emergency stop systems, and interlocks to meet regional safety standards (e.g., OSHA, CE directives).

Tailored solutions allow integration into diverse manufacturing environments.

By collaborating with experienced engineers, companies can ensure their polishing solution is not merely a purchase but a strategic investment designed for maximum efficiency and return on investment.

Application Case Studies: Real-World Impact

The tangible benefits of a high-quality steel pipe polishing machine are best illustrated through real-world applications.

Case Study 1: Large-Scale Petrochemical Pipeline Project

A major international petrochemical company faced challenges with premature internal corrosion and flow restrictions in their carbon steel pipelines. Manual polishing methods were inconsistent and time-consuming. They invested in a multi-station wet steel pipe polish machine capable of processing pipes up to 150mm in diameter at high speeds.

- Challenge: Inconsistent internal surface roughness (Ra 3.2 µm - 6.3 µm) leading to scale buildup and accelerated corrosion.

- Solution: Implementation of a 10-station wet polishing machine with automated feeding.

- Result: Achieved consistent internal surface roughness of Ra 0.8 µm - 1.2 µm, reducing frictional pressure drops by 15% and extending projected pipeline service life by 30% through improved corrosion resistance. Operational efficiency increased by 400% compared to previous methods.

Case Study 2: High-Purity Pharmaceutical Tubing

A leading pharmaceutical equipment manufacturer required ultra-hygienic stainless steel tubing (316L) for bioreactors and sterile fluid transfer systems. Their existing finishing process struggled to consistently meet the strict Ra

- Challenge: Inconsistent internal surface finish on small-diameter stainless steel tubes, failing to meet strict pharmaceutical hygienic standards.

- Solution: Adoption of a specialized small-diameter, multi-head wet polishing machine with precise abrasive control and advanced filtration for the coolant.

- Result: Consistently achieved internal Ra values below 0.3 µm, significantly reducing bioburden risk and enabling full compliance with regulatory requirements. Rejection rates for tubing decreased by 70%, leading to substantial material and labor savings.

Achieving superior finishes for critical industrial applications.

Trustworthiness and Support: FAQ, Lead Time, Warranty, and Customer Service

Establishing trust with B2B clients goes beyond product specifications, encompassing transparent operational details and robust after-sales support.

Frequently Asked Questions (FAQ)

A1: Standard models generally have a lead time of 6-8 weeks, while highly customized solutions may require 10-14 weeks, depending on complexity and component sourcing. Detailed timelines are provided upon order confirmation.

A2: Our machines are designed to achieve a wide range of surface finishes, from descaling and rust removal (rough finish) to mirror-like polishes, typically ranging from Ra 1.6 µm down to Ra 0.2 µm, depending on the number of polishing stages and abrasive types used.

A3: Yes, comprehensive operational and maintenance training is provided upon installation, either on-site or remotely via detailed video tutorials and live sessions, ensuring your team is fully proficient.

A4: The wet polishing system includes a multi-stage filtration unit to remove abrasive particles and metal fines, extending coolant life. Wastewater management options, including closed-loop systems and effluent treatment solutions, can be integrated based on local environmental regulations.

Lead Time and Fulfillment

Our manufacturing process is optimized for efficiency without compromising quality. Upon receipt of a confirmed order and technical specifications, a detailed production schedule is provided. We leverage a robust supply chain to ensure timely procurement of high-quality components, enabling reliable fulfillment within quoted lead times. International shipping logistics are meticulously handled, ensuring secure and timely delivery to your facility.

Warranty Commitments

All our steel pipe polishing machine units come with a standard 12-month warranty from the date of commissioning or 18 months from shipment (whichever comes first). This covers manufacturing defects and component failures under normal operating conditions. Extended warranty options and comprehensive service contracts are available for enhanced peace of mind.

Customer Support and After-Sales Service

Our commitment extends well beyond the sale. We offer:

- Remote Technical Support: Available via phone, email, and video conferencing for troubleshooting and operational assistance.

- On-Site Service: Skilled technicians are available for installation, commissioning, preventative maintenance, and repair services globally.

- Spare Parts Availability: A comprehensive inventory of genuine spare parts is maintained for quick dispatch, minimizing downtime.

- Maintenance Programs: Customized maintenance schedules and service plans to ensure optimal machine performance and longevity.

References

- International Organization for Standardization (ISO) official website.

- American Society of Mechanical Engineers (ASME) standards.

- European Committee for Standardization (CEN) - CE Marking Guidelines.

- Materials Performance & Corrosion Control Journals.

- Fluid Mechanics and Tribology Academic Papers.