The Best Centerless Valve Grinder A Comprehensive Overview

In the world of precision machining, the centerless valve grinder has carved out a niche as an indispensable tool for enhancing the performance and longevity of engine components. Whether in an automotive repair shop or a manufacturing facility, the need for efficient and accurate valve grinding is paramount. This article delves into the features, advantages, and recommendations for selecting the best centerless valve grinder.

Centerless grinding is a method that allows for consistent and precise shaping of cylindrical parts without the need for a fixed component. This technique is especially beneficial in valve grinding, where maintaining tight tolerances is crucial. The centerless valve grinder differs from traditional grinders by eliminating the need for clamping the workpiece, thereby speeding up the process and increasing productivity.

Key Features to Consider

1. Precision and Accuracy When selecting a centerless valve grinder, precision is of utmost importance. Look for models with electronic controls, enabling fine adjustments and ensuring that each valve is ground to exact specifications.

2. Versatility The capability to handle various valve sizes and materials is essential. Opt for grinders that can accommodate both intake and exhaust valves, and those that can grind different materials like aluminum and steel.

3. Ease of Use User-friendly controls and automated features can significantly enhance operational efficiency. Grinders with intuitive interfaces reduce the learning curve for new operators and enhance overall productivity.

4. Durability Investing in a robust machine can yield significant long-term benefits. Look for grinders that feature high-quality components and construction that can withstand the rigors of daily use.

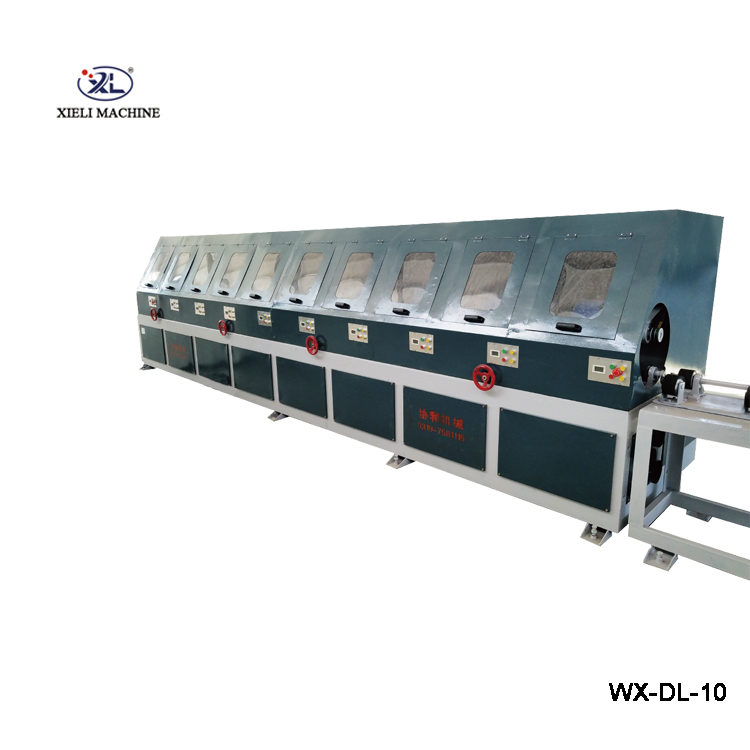

best centerless valve grinder

5. Maintenance and Support A reputable manufacturer provides excellent customer support and readily available parts. Periodic maintenance is vital to ensure your grinder operates optimally, so consider brands that offer comprehensive service plans.

Advantages of Centerless Valve Grinders

One of the primary advantages of using a centerless valve grinder is the speed of operation. Traditional grinding methods often require multiple setups, whereas centerless grinding allows for continuous operation, leading to improved throughput. Additionally, the absence of clamping means that setup times are minimized, further enhancing productivity.

Moreover, centerless grinding provides superior finish quality. The process creates a smoother surface compared to conventional methods, which is critical for valves that must seal tightly against combustion chambers. The enhanced finish contributes to better performance and longer service life.

Top Recommendations

When it comes to choosing the best centerless valve grinder, a few brands stand out for their reliability and performance. The Chuck's Precision Grinders line is commonly recognized for their robust build and precise grinding capabilities. CNC Industries also offers high-tech models equipped with advanced automation features that cater to modern manufacturing demands.

In conclusion, the best centerless valve grinder is one that offers precision, versatility, and durability while being user-friendly. By understanding the key features and advantages of these machines, businesses can make informed decisions that enhance their machining operations and contribute to long-term success. Investing in a high-quality centerless valve grinder is not just a choice; it's a commitment to excellence in performance and reliability.