Exploring Surface Polishing Machine Suppliers A Guide for Your Business Needs

In today’s manufacturing landscape, surface finishing plays a pivotal role in enhancing the durability and aesthetic appeal of products. To achieve a high-quality finish, businesses often turn to specialized equipment such as surface polishing machines. These machines are essential for various industries, including metalworking, woodworking, automotive, and electronics. As the demand for superior finishing techniques continues to grow, choosing the right supplier for surface polishing machines is crucial for effectively meeting production goals.

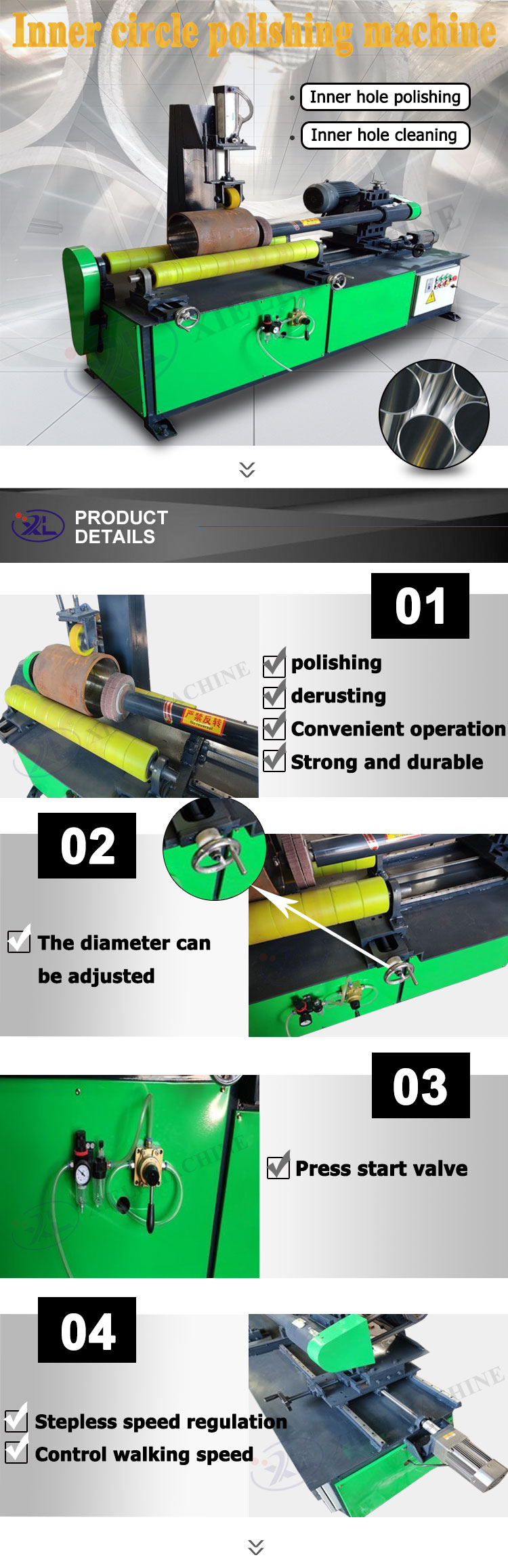

When embarking on a search for a surface polishing machine supplier, several factors warrant consideration. First and foremost, it’s essential to evaluate the range of machines offered. Various models exist, each designed for specific applications. For example, some machines focus on metal surfaces, while others are tailored for wood or plastic. A reputable supplier should provide a diverse array of options, including manual, semi-automatic, and fully automatic machines, ensuring that businesses can find the right fit for their specific production needs.

Another critical aspect is the supplier’s industry experience and reputation. Companies with a solid track record are more likely to provide reliable equipment and customer service. They should offer not only high-quality machines but also comprehensive after-sales support, including maintenance, training, and spare parts availability. Researching reviews and testimonials from other businesses can help gauge the reliability and effectiveness of a supplier.

surface polishing machine supplier

Moreover, exploring the technological advancements integrated into the surface polishing machines is crucial. Modern machines may include features such as programmable controls, adaptive speed settings, and robotic automation, which enhance precision and efficiency. Suppliers that invest in the latest technologies often provide a competitive edge, helping businesses improve their production processes and reduce labor costs.

Cost is another important factor when selecting a surface polishing machine supplier. While it may be tempting to choose the cheapest option available, it’s vital to consider the long-term value. A well-built machine from a reputable supplier may have a higher initial cost but can lead to savings over time due to lower maintenance needs and increased durability. Requesting quotes from multiple suppliers and comparing them based on features, warranty, and support can aid in making an informed decision.

Lastly, consider the geographical location of the supplier. Proximity can impact shipping costs and lead times for obtaining parts or servicing equipment. Suppliers within your region may provide faster response times for maintenance and support, which can minimize downtime in your production line.

In conclusion, selecting the right surface polishing machine supplier is a critical step in achieving high-quality finishes for your products. By considering the range of machines offered, supplier reputation, technological advancements, cost, and geographical location, businesses can make informed decisions that align with their production goals. Investing in the right equipment and support can significantly enhance operational efficiency and product quality, positioning companies for success in a competitive marketplace. With the right supplier by your side, the path to achieving exceptional surface finishes becomes a reality.