Understanding the ODM Square Rectangle Tube Polishing Machine

In the world of manufacturing and fabrication, the finishing process is as critical as the initial stages of production. One primary focus of this finishing process is polishing—enhancing the surface quality of products to achieve the desired aesthetic and functional characteristics. Among the many tools designed for this purpose, the ODM square rectangle tube polishing machine stands out for its efficiency and precision in polishing tubular materials.

Introduction to ODM Polishing Machines

The ODM (Original Design Manufacturer) square rectangle tube polishing machine is engineered specifically to cater to the needs of industries that require high-quality finishes on square and rectangular tubes. This versatile machine accommodates various materials, including stainless steel, aluminum, and other metals, making it an essential asset in sectors such as automotive, construction, and furniture manufacturing.

Key Features

One of the most significant attributes of the ODM polishing machine is its automated functionality. This ensures a consistent and uniform polish across all surfaces, reducing the possibility of human error that can occur in manual polishing processes. The machine employs advanced technology to control speed, pressure, and polishing time, which can be adjusted according to the material type and desired finish.

The machine is typically equipped with multiple polishing heads that can rotate around the tube, ensuring that every edge and surface receives equal attention

. This multi-head system not only improves efficiency but also significantly speeds up the production process—crucial for industries where time is money.The Polishing Process

The polishing process generally involves several stages. Initially, the tube may undergo a grinding phase to remove any rough edges or imperfections. Following this, the actual polishing phase begins, using abrasive materials to achieve a polished finish. The ODM machine’s design enables it to use a range of polishing belts and pads, allowing manufacturers to select the best options for their specific needs.

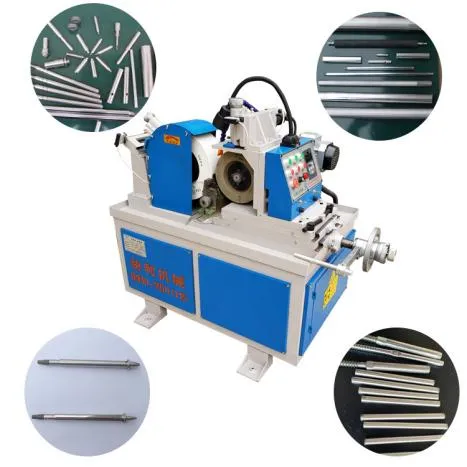

odm square rectangle tube polishing machine

The entire process is streamlined, often integrated with feeding and unloading systems that enhance productivity. By automating the loading and unloading of materials, the machine minimizes downtime and optimizes workflow, ensuring a continuous production line.

Benefits of Using ODM Machines

Investing in an ODM square rectangle tube polishing machine offers numerous advantages. Firstly, the enhanced surface quality leads to better aesthetic appeal and may contribute to a product’s functional longevity. A polished surface can reduce friction in applications, enhance corrosion resistance, and minimize maintenance costs over time.

Secondly, the machine’s efficiency translates into cost savings for businesses. The capability to process multiple tubes simultaneously reduces labor costs and minimizes the time required to achieve the desired finish. Additionally, a consistent quality output increases customer satisfaction, leading to repeat business and credibility within the marketplace.

Versatile Applications

The versatility of the ODM polishing machine allows it to be utilized across various industries. In the automotive sector, polished tubes are often used for exhaust systems and aesthetic components. In construction, these tubes find applications in structural supports and decorative elements. Additionally, in the furniture industry, polished tubing is integral to producing high-end aesthetic finishes.

Conclusion

The ODM square rectangle tube polishing machine represents a significant advancement in the polishing technology landscape. It combines automation, efficiency, and precision, catering to the diverse needs of modern manufacturing. As industries continue to prioritize high-quality finishes, investing in such sophisticated machinery will undoubtedly provide a competitive edge, ensuring that products not only meet but exceed market standards. Embracing this technology positions businesses to thrive in a fast-paced, quality-driven environment.