The Importance of Round Tube Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, the aesthetic and functional quality of products holds immense significance. One crucial process that enhances the quality of metal products is polishing, particularly when it comes to round tubes. Round tube polishing machines play a pivotal role in achieving a smooth and shiny finish, which is not just about appearance but also about performance and durability.

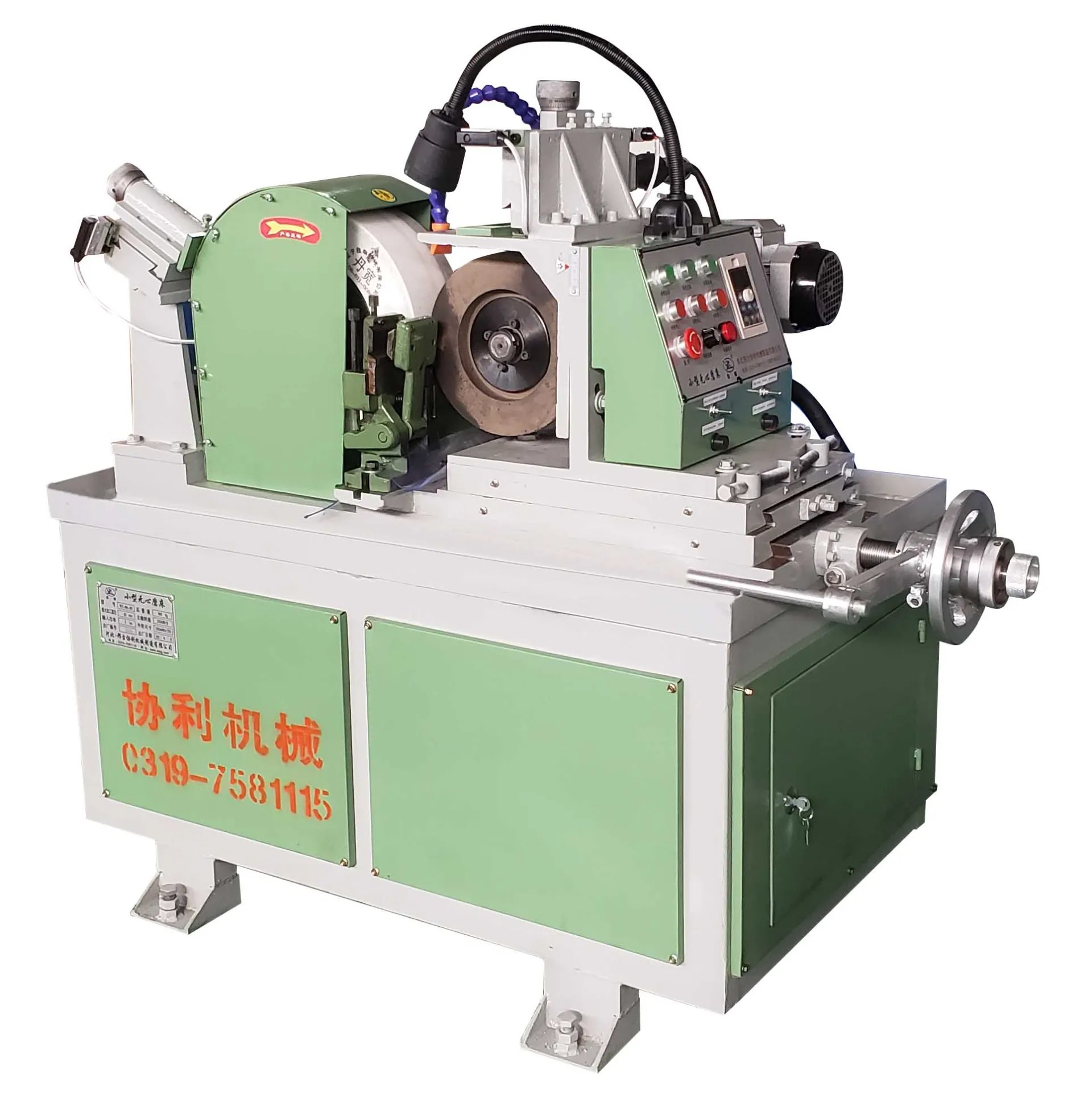

Round tube polishing machines are specialized equipment designed to improve the surface finish of cylindrical metal tubes. These machines operate on the principle of mechanical abrasion, utilizing various polishing compounds and techniques to remove imperfections from the metal surface. This process is essential in multiple industries, including automotive, aerospace, food processing, and medical device manufacturing, where the quality of materials directly affects the safety and efficiency of the end products.

One of the primary advantages of using a round tube polishing machine is its ability to enhance the aesthetic appeal of products. A polished surface not only looks more professional but also conveys a sense of quality and meticulous attention to detail. Customers are more likely to trust and prefer products that exhibit a high-quality finish, which can significantly impact a company’s reputation and sales.

Moreover, the polishing process improves the corrosion resistance of metal surfaces. By removing microscopic imperfections, the surface becomes less susceptible to oxidation and other forms of degradation. This is particularly important in industries such as food processing, where maintaining hygiene and preventing contamination are critical. Polished surfaces are easier to clean and maintain, ensuring compliance with safety regulations and standards.

round tube polishing machine

The efficiency and productivity of manufacturing operations can also be greatly enhanced with the use of round tube polishing machines. Manual polishing is labor-intensive and time-consuming, often resulting in variable quality due to human error. In contrast, automated polishing machines provide consistent results with minimal oversight. This not only saves time and labor costs but also allows manufacturers to scale production while ensuring high-quality outputs.

Various types of round tube polishing machines are available, each designed for specific applications. For instance, some machines utilize a belt polishing system, while others may use rotary brushes or buffing pads. The choice of machine often depends on the material of the tubes, the desired finish, and the production volume. Advanced models incorporate features such as programmable controls and automated feeding systems, allowing for greater flexibility and efficiency.

In addition to improving surface quality, the use of round tube polishing machines also aligns with modern sustainability practices. By maximizing the life of products through effective surface treatment, manufacturers can reduce waste and minimize the environmental impact of their operations. Enhanced durability means products need to be replaced less frequently, leading to lower raw material consumption and reduced manufacturing emissions.

In conclusion, round tube polishing machines are invaluable assets in today’s manufacturing landscape. They not only contribute to the aesthetic and functional quality of products but also enhance efficiency, productivity, and sustainability. As industries continue to evolve, investing in advanced polishing technology will become increasingly important for manufacturers aiming to meet the high standards of quality demanded by consumers and regulatory bodies alike. Embracing these technologies will not only improve individual product offerings but will also bolster the overall competitiveness of manufacturing operations in the global market.