Introduction to High-Precision Centerless Grinding Technology

In the realm of precision manufacturing, the ability to produce components with exceptionally tight tolerances and superior surface finishes is paramount. Centerless grinding stands as a cornerstone technology for achieving these demanding specifications, particularly for cylindrical workpieces. Unlike traditional cylindrical grinding, centerless grinding eliminates the need for work-holding centers, allowing for continuous, high-volume production with unparalleled concentricity and speed. At the forefront of this innovation are machines capable of delivering the ultimate in accuracy and efficiency, often exemplified by a high quality centerless grinder cincinnati. These systems are engineered to meet the rigorous demands of modern industries, from automotive and aerospace to medical and hydraulic components, ensuring that every part meets or exceeds global quality benchmarks.

This article will delve into the critical aspects of high-performance centerless grinding technology, exploring industry trends, technical capabilities, application versatility, and the strategic advantages offered by advanced systems. We will also examine the intricate manufacturing processes that contribute to the longevity and precision of these machines, along with their role in achieving superior surface finishes, such as those provided by a high quality stainless steel pipe mirror polishing machine.

Current Industry Trends and Market Dynamics in Precision Grinding

The precision grinding industry is currently experiencing significant growth driven by several key trends. Automation and digitalization are transforming manufacturing floors, leading to an increased demand for high quality cnc centerless grinder suppliers. These advanced machines offer enhanced control, reduced setup times, and the ability to process complex geometries with minimal human intervention. Furthermore, there is a strong emphasis on energy efficiency and sustainability, pushing manufacturers to develop grinding solutions that minimize power consumption and waste.

Emerging markets and the reshoring of manufacturing operations are also contributing to the demand for robust and reliable grinding equipment. Industries are continuously seeking solutions that offer a competitive high quality metal polishing machine price without compromising on performance or longevity. The integration of artificial intelligence (AI) and machine learning (ML) for predictive maintenance and process optimization is another frontier, promising to further enhance the efficiency and reliability of centerless grinding operations. The need for specialized applications, such as the production of medical implants, aerospace components, and advanced automotive parts, fuels the innovation in this sector, demanding ever-higher levels of precision and surface integrity from machines like a high quality mikrosa cnc centerless grinder.

Technical Specifications and Capabilities of Advanced Centerless Grinders

Modern centerless grinders are sophisticated machines designed for extreme precision and high throughput. A premium high quality centerless grinder cincinnati, for instance, typically boasts an array of features that set it apart. These include robust hydrostatic or anti-friction bearing grinding wheel spindles, which provide exceptional rigidity and vibration damping, crucial for achieving mirror finishes and tight tolerances. CNC controls with intuitive interfaces allow for precise adjustment of grinding parameters, automatic compensation for wheel wear, and quick changeovers between different workpiece dimensions.

Key technical parameters often include grinding wheel diameter and width, regulating wheel diameter and width, maximum workpiece diameter, and the power of both the grinding and regulating wheel motors. Automation features, such as automated loading/unloading systems, in-process gauging, and automatic wheel dressing, contribute significantly to increased productivity and reduced labor costs. The ability to handle various materials, from hardened steels and carbides to ceramics and exotic alloys, further underscores the versatility of these machines.

Typical Product Specifications Table (General High-End Centerless Grinder)

| Parameter | Specification |

|---|---|

| Max Workpiece Diameter | 0.5 mm - 150 mm |

| Grinding Wheel Diameter | 300 mm - 610 mm |

| Grinding Wheel Width | 100 mm - 400 mm |

| Grinding Wheel Motor Power | 15 kW - 75 kW |

| Regulating Wheel Diameter | 200 mm - 350 mm |

| Regulating Wheel Speed | 10 - 250 RPM (variable) |

| Tolerance Achievable (Roundness) | Typically < 0.5 µm |

| Surface Finish Achievable (Ra) | Typically < 0.05 µm |

| Control System | Siemens 840D/Fanuc 31i-B5 CNC |

Detailed Process Flow: From Raw Material to Precision Finish

The manufacturing process for a high quality centerless grinder cincinnati, or any high-precision grinding machine, involves a meticulous series of steps to ensure ultimate performance and longevity. It begins with the selection of premium materials and extends through highly controlled fabrication and assembly, culminating in rigorous testing.

Machine Component Manufacturing Process:

- Material Selection: The foundation of the machine, such as the bed and wheel heads, typically utilizes high-grade Meehanite cast iron, renowned for its excellent vibration damping characteristics and dimensional stability. Critical components like spindles and guide ways are forged from high-alloy steels, chosen for their superior hardness, wear resistance, and fatigue strength.

- Initial Forming (Casting & Forging): Large structural components undergo precision casting processes, followed by stress relieving to prevent distortion. Smaller, high-stress parts are forged to refine their grain structure and enhance mechanical properties.

- Rough Machining & Heat Treatment: Components are rough machined to remove excess material, then subjected to specific heat treatments (e.g., induction hardening, carburizing) to achieve the required surface hardness and core toughness. This step is critical for the durability of moving parts.

- Precision CNC Machining: Multi-axis CNC machining centers are employed for all critical surfaces and features, ensuring geometric accuracy down to micron levels. This includes milling, boring, and drilling operations, all monitored by in-process probing systems.

- Grinding & Lapping: Guide ways and bearing surfaces undergo precision grinding and subsequent hand-lapping or superfinishing to achieve extreme flatness and surface finish, crucial for smooth operation and minimal friction.

- Assembly & Integration: Components are meticulously assembled in a cleanroom environment. Hydraulic, pneumatic, and electrical systems are integrated, with careful attention to alignment and calibration.

- Quality Control & Testing: Each machine undergoes stringent Factory Acceptance Tests (FAT) against international standards such as ISO 9001 for quality management and ANSI B7.1 for grinding wheel safety. Geometric accuracy, thermal stability, vibration analysis, and performance under load are all verified. A typical service life for these machines, with proper maintenance, exceeds 15-20 years.

Workpiece Processing Flow (Example: SS Pipe Polishing)

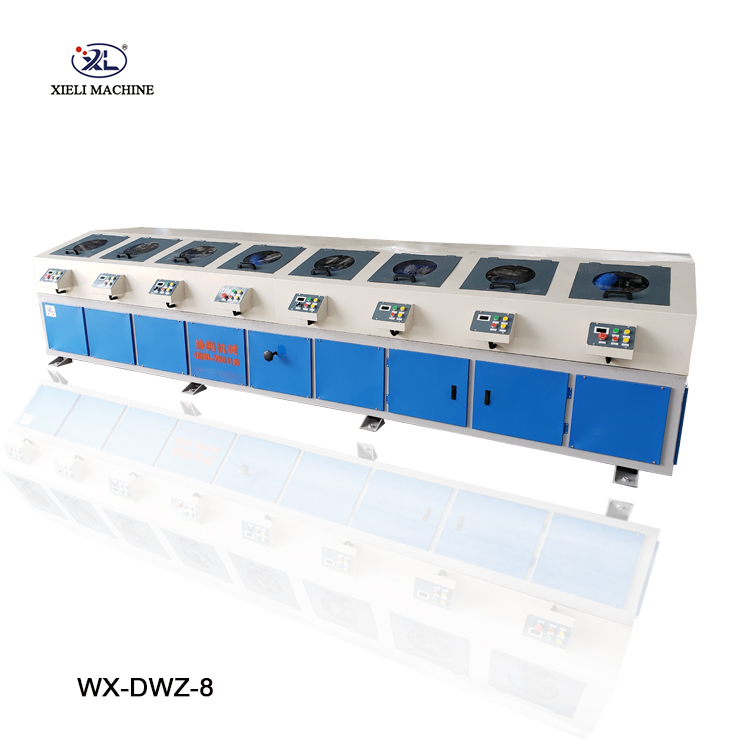

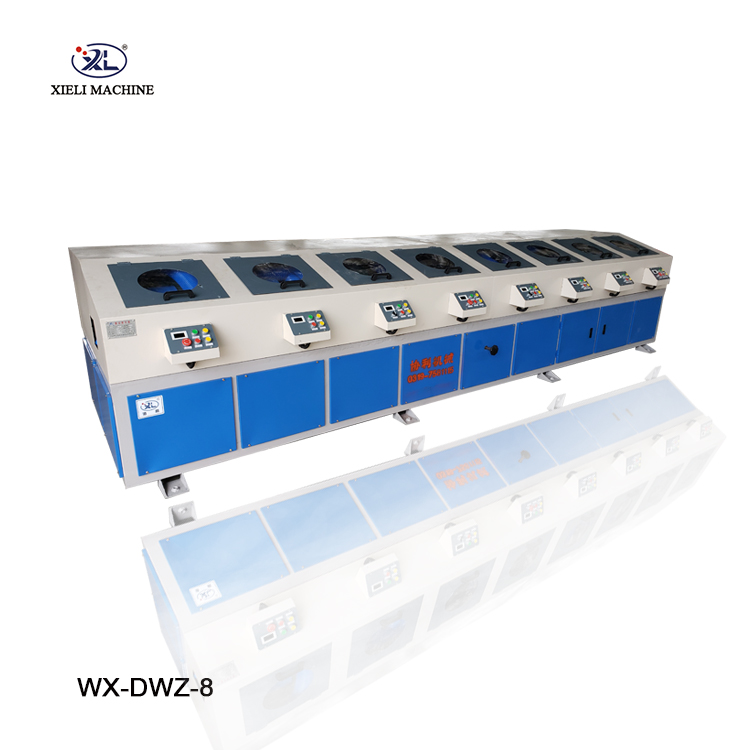

Consider the example of preparing stainless steel pipes. While a primary centerless grinder focuses on dimensional accuracy, subsequent processes often involve machines that utilize a similar centerless principle for surface finishing. The "New SS pipe outer round rust removal polishing machine" from Xielizz (as referenced by the initial keyword link) exemplifies this. Here's a typical flow:

- Raw Material Input: Stainless steel pipes, potentially after initial drawing or welding processes, are fed into the system. These pipes might have surface imperfections, scale, or light rust.

- Initial Grinding/Rough Polishing: For significant material removal or to correct major defects, the pipes might pass through a conventional centerless grinder or a coarse abrasive belt unit operating in a centerless configuration.

- Rust Removal & Intermediate Polishing: The pipes then enter a specialized polishing machine, such as a high quality pipe polishing machine. This machine uses multiple abrasive belts or wheels arranged around the pipe, much like a centerless grinder, to remove rust, scale, and achieve a uniform surface finish. The regulating wheel ensures continuous, controlled feed.

- Fine Polishing & Mirror Finishing: Subsequent stages utilize progressively finer abrasives (e.g., non-woven belts, buffing wheels with polishing compounds) to achieve a desired surface roughness (Ra value) and even a mirror-like finish. This is where a high quality stainless steel pipe mirror polishing machine excels.

- Cleaning & Inspection: After polishing, pipes are thoroughly cleaned to remove any abrasive residues or compounds. They then undergo stringent visual and instrumental inspection (e.g., surface roughness testers) to ensure quality.

Target Industries: These highly precise machines are vital in diverse sectors including petrochemical (for corrosion-resistant valve stems and pipeline components), metallurgy (for finishing various metal rods and bars), water supply & drainage (for high-grade pipe finishing and valve components), automotive (transmission shafts, piston pins), and aerospace (landing gear components, turbine shafts). Advantages demonstrated in these scenarios include significant energy saving due to optimized grinding parameters and efficient motor designs, and enhanced corrosion resistance of finished parts due to superior surface integrity and absence of defects.

Versatile Application Scenarios for Precision Grinders

The versatility of a modern centerless grinder allows it to cater to an extensive range of application scenarios across various industries. From the initial processing of raw materials to the final finishing of critical components, these machines are indispensable. In the automotive industry, for example, centerless grinders are used to produce camshafts, crankshafts, piston pins, valve stems, and transmission shafts, where precision and surface finish are critical for engine performance and longevity. The aerospace sector relies on them for manufacturing landing gear components, turbine shafts, and various fasteners that demand exceptionally tight tolerances and high material integrity.

For the medical device industry, centerless grinding is essential for fabricating surgical instruments, dental implants, and prosthetics, all of which require biocompatibility and ultra-smooth surfaces. The hydraulic and pneumatic industries utilize these grinders for piston rods, valve spools, and pump shafts, where precise fits are crucial for sealing and operational efficiency. Furthermore, for continuous bar and rod grinding, the capabilities of a high quality pipe polishing machine suppliers machine can be extended to handle long workpieces, demonstrating their adaptability beyond discrete parts. Even smaller-scale operations benefit from solutions like a high quality table top centerless grinder for precision part finishing in a compact footprint.

Technical Advantages and Innovative Features

The technical advantages of a state-of-the-art centerless grinder are manifold, translating directly into tangible benefits for manufacturing operations. Key among these is the superior precision achieved through advanced machine design, including hydrostatic bearings that eliminate stick-slip friction and minimize thermal deformation. This leads to exceptional roundness, straightness, and surface finish on ground parts. Efficiency is dramatically enhanced by automated loading and unloading systems, allowing for continuous, lights-out operation and significantly higher throughput compared to traditional grinding methods.

Modern CNC controls provide unparalleled flexibility and repeatability, enabling operators to program complex grinding cycles and store parameters for various workpieces. This reduces setup times and minimizes human error, contributing to a lower cost per part. Furthermore, features like automatic wheel balancing, in-process gauging, and closed-loop feedback systems ensure consistent quality and adapt to minor process variations in real-time. For industries requiring specialized solutions, machines like a high quality monza 4 centerless grinder for sale offer unique configurations for specific applications, further underscoring the innovative capabilities within the sector.

Vendor Comparison and Product Ecosystems

When selecting a centerless grinding solution, a comprehensive vendor comparison is crucial. While a specific high quality centerless grinder cincinnati represents a benchmark in terms of quality and innovation, the market offers a range of options, each with distinct advantages. Vendors differentiate themselves not only on machine specifications but also on their service ecosystem, customization capabilities, and technological partnerships. Key comparison criteria include:

- Precision and Accuracy: Sub-micron level accuracy for roundness and straightness.

- Automation and Control: Sophistication of CNC systems, ease of programming, and integration with factory automation.

- Material Versatility: Ability to effectively grind a wide range of materials without significant retooling.

- Service and Support: Availability of spare parts, technical support, training, and maintenance contracts.

- Customization Options: Ability to tailor machines for unique applications or integration into existing production lines.

- Longevity and Reliability: Track record of machine durability and minimal downtime, often exemplified by the reputation of leading brands. Even a well-maintained high quality old centerless grinding machine can still provide decades of reliable service.

Product Comparison Table: Standard vs. Advanced Centerless Grinder

| Feature | Standard Centerless Grinder | Advanced CNC Centerless Grinder |

|---|---|---|

| Control System | Manual or Basic PLC | Full CNC (Siemens/Fanuc), Touch Screen HMI |

| Bearing Type | Anti-friction/Plain Bearings | Hydrostatic or High-Precision Anti-friction |

| Roundness Accuracy | ~1-2 µm | < 0.5 µm |

| Surface Finish (Ra) | ~0.2-0.4 µm | < 0.05 µm |

| Automation | Manual loading, basic dressing | Auto loading/unloading, in-process gauging, auto dressing/compensation |

| Energy Efficiency | Standard motors | IE3/IE4 motors, energy recovery systems |

Customized Solutions for Niche Applications

Recognizing that off-the-shelf solutions may not always meet the unique challenges of specialized manufacturing, leading suppliers offer extensive customization options for their centerless grinding machines. These tailored solutions ensure that the equipment perfectly integrates with existing production lines and addresses specific material or geometric requirements. Customization can range from adapting the grinding and regulating wheel configurations for unusual workpiece dimensions (e.g., extremely long bars or very small pins) to integrating specialized automation for delicate part handling.

Furthermore, custom cooling systems, filtration units, and acoustic enclosures can be designed to meet environmental or operational constraints. For applications requiring specific surface textures or multi-stage grinding processes, the machine’s CNC program can be specifically developed to execute complex sequences. This level of customization is a testament to the engineering prowess behind a truly high quality centerless grinder cincinnati, ensuring that manufacturers can achieve optimal results for even the most demanding niche applications, from aerospace components to medical instruments.

Application Case Studies & Customer Successes

The real-world impact of high-quality centerless grinding technology is best illustrated through successful application case studies. For instance, a major automotive supplier implemented a new CNC centerless grinding line to produce engine valve stems. By upgrading from older, manually operated machines to a modern, automated high quality cnc centerless grinder suppliers solution, they achieved a 30% reduction in cycle time, a 50% decrease in scrap rates, and improved the average surface finish from Ra 0.2 µm to Ra 0.08 µm, exceeding OEM specifications. This resulted in significant cost savings and enhanced engine performance.

Another case involves a manufacturer of precision hydraulic components. They needed to achieve exceptionally tight roundness tolerances on pump shafts made from hardened steel. By utilizing a hydrostatic-bearing equipped centerless grinder, they consistently achieved a roundness of less than 0.3 µm, a level previously unattainable with their existing equipment. This precision led to improved efficiency and extended service life for their hydraulic pumps, solidifying their reputation for product quality.

In a challenging scenario, a medical device company required mirror-polished surfaces on titanium implant components to ensure biocompatibility and prevent bacterial adhesion. Implementing a multi-stage centerless polishing system, similar to a high quality pipe polishing machine with specialized fine abrasive belts, allowed them to achieve a surface finish of Ra < 0.02 µm. The automated nature of the system also minimized manual handling, reducing contamination risks and ensuring consistent, repeatable results critical for regulatory compliance.

Ensuring Quality, Trustworthiness, and Support ( Principles)

Adherence to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) guidelines is fundamental in the B2B sector, particularly for high-value capital equipment like centerless grinders. Manufacturers demonstrate this through rigorous certification, robust customer support, and transparent communication.

Certifications and Standards

- ISO 9001: Certification for Quality Management Systems, ensuring consistent product quality and continuous improvement.

- CE Marking: Compliance with European health, safety, and environmental protection standards.

- ANSI B7.1: Standards for the use, care, and protection of abrasive wheels.

- Environmental Certifications: Adherence to directives like RoHS (Restriction of Hazardous Substances) where applicable, demonstrating commitment to sustainable manufacturing practices.

Lead Time, Warranty, and After-Sales Support

Typical lead times for custom or advanced centerless grinders can range from 12 to 24 weeks, depending on complexity and customization. Standard models often have shorter lead times of 8-12 weeks. Most reputable manufacturers offer a standard warranty of 12-24 months on parts and labor, with extended warranty options available. Comprehensive after-sales support includes:

- Installation and Commissioning: On-site expert assistance to ensure proper setup and initial operation.

- Operator Training: In-depth training programs for machine operators and maintenance personnel.

- Technical Support: 24/7 remote and on-site technical assistance to address operational issues.

- Spare Parts Availability: A readily available inventory of genuine spare parts to minimize downtime.

- Preventative Maintenance Programs: Scheduled maintenance services to prolong machine life and ensure optimal performance.

Frequently Asked Questions (FAQ)

Q: What is the primary advantage of centerless grinding over traditional cylindrical grinding?

A: Centerless grinding offers significantly higher production rates, continuous operation, and superior concentricity as the workpiece is supported by its own periphery, eliminating errors from centers. It also simplifies fixturing for long workpieces.

Q: Can a centerless grinder process non-ferrous metals or ceramics?

A: Yes, with appropriate grinding wheels (e.g., diamond or CBN for ceramics and hard materials) and proper coolant systems, modern centerless grinders are highly versatile and can effectively process a wide array of materials, including non-ferrous alloys, ceramics, and even certain plastics.

Q: What kind of surface finishes can be achieved with a high quality centerless grinder cincinnati?

A: High-quality centerless grinders can consistently achieve surface finishes of Ra 0.1 µm and often as fine as Ra 0.05 µm or better, depending on the material, wheel type, and process optimization. This is essential for applications requiring mirror-like surfaces.

Q: How do these machines contribute to energy savings?

A: Modern centerless grinders incorporate energy-efficient motors (IE3/IE4 standards), optimized hydraulic systems, and sometimes regenerative braking systems. Their high processing speed and reduced scrap also lead to overall energy savings per part produced.

Conclusion

The role of a high quality centerless grinder cincinnati in today's precision manufacturing landscape is undeniable. These machines are not merely tools for material removal; they are advanced engineering systems that deliver unparalleled accuracy, efficiency, and surface quality. By integrating cutting-edge technology, robust construction, and comprehensive support, leading manufacturers ensure that their centerless grinding solutions meet the evolving demands of industries striving for higher performance and greater competitiveness. Investing in such technology is a strategic decision that yields long-term benefits in productivity, product quality, and operational cost savings, underpinning the future of advanced manufacturing.

References

- Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson.

- Malkin, S. (2009). Grinding Technology: Theory and Applications of Machining with Abrasives. Industrial Press.

- ASM Handbook, Volume 16: Machining. (2004). ASM International.

- International Organization for Standardization (ISO) Official Website. www.iso.org

- American National Standards Institute (ANSI) Official Website. www.ansi.org