Working Principle of Centerless Grinding Machine

Centerless grinding is a highly efficient production process that enables precise machining of cylindrical components without the need for a centering fixture. The process utilizes a unique arrangement of components that allows for the grinding of material while maintaining a consistent and accurate diameter. This article delves into the working principle of a centerless grinding machine, exploring its mechanism, advantages, and applications.

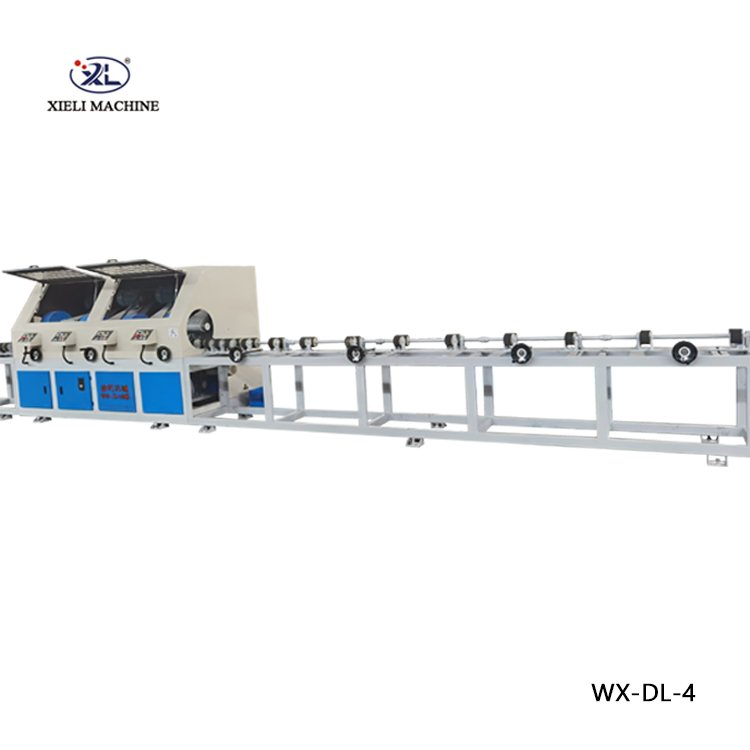

At its core, the centerless grinding machine consists of three primary components the grinding wheel, the regulating wheel, and the workpiece support. The grinding wheel is responsible for removing material from the workpiece, which is typically cylindrical. The regulating wheel, on the other hand, controls the speed and position of the workpiece as it is being ground, while the workpiece support aids in stabilizing the material during the grinding operation.

The workpiece is fed into the machine between the grinding and regulating wheels, which are positioned at an angle to one another. This configuration allows for the effective removal of material without the need for the workpiece to be centered in a fixture. As the grinding wheel rotates at a high speed, it applies pressure to the workpiece, effectively grinding it to the desired diameter. Meanwhile, the regulating wheel, which operates at a slower speed, provides the necessary support and guides the movement of the workpiece as it advances through the machine.

One of the primary advantages of centerless grinding is its ability to process multiple workpieces simultaneously. Unlike traditional grinding methods, which often require a fixed position for the workpiece, centerless grinding allows for continuous operation. This efficiency is particularly beneficial in high-volume production settings, as it significantly reduces cycle times and increases overall productivity.

working principle of centerless grinding machine

Additionally, centerless grinding machines can accommodate a wide range of materials, including metals, plastics, and ceramics

. The adaptability of this process makes it a popular choice for industries such as automotive, aerospace, and manufacturing, where precision and efficiency are critical.Another significant benefit of centerless grinding is the minimal setup time required. Since there are no elaborate fixtures needed to hold the workpiece, operators can quickly switch between different sizes and shapes of components, making it ideal for manufacturers who need to produce a variety of items in small batches.

However, the success of centerless grinding relies heavily on precise alignment and maintenance of the grinding and regulating wheels. If either wheel becomes worn or misaligned, it can lead to inconsistencies in the finished product. Regular maintenance, along with periodic checks and adjustments, is crucial to ensure optimal performance.

In conclusion, the working principle of centerless grinding machines offers a highly efficient and versatile solution for shaping cylindrical components. Its unique design eliminates the need for centering fixtures, allowing for continuous operation and reduced cycle times. With applications across multiple industries and the ability to handle various materials, centerless grinding remains a vital process in modern manufacturing, providing both precision and productivity. As technology advances, it is likely that even greater efficiencies and capabilities will emerge, further enhancing the role of centerless grinding in the industrial landscape.