The Imperative of Precision: Understanding High-Quality Centerless Belt Grinding and Polishing Machines

In the realm of advanced manufacturing, achieving superior surface finish and precise dimensional accuracy is paramount. This is especially true for industries relying on cylindrical components, where consistency and quality directly impact performance and longevity. The high quality centerless belt grinding polishing machine stands as a cornerstone technology in meeting these stringent demands. Its ability to process workpieces without needing center support, employing abrasive belts for both grinding and polishing, offers unparalleled efficiency and finish quality across a diverse range of materials and applications.

The market for these sophisticated machines is currently experiencing significant growth, driven by increasing automation in manufacturing, the demand for higher product aesthetics, and the need for enhanced material performance through optimized surface integrity. Industries such as automotive, aerospace, medical device manufacturing, and general precision engineering are pushing the boundaries for surface finishing, making investments in advanced grinding and polishing solutions a strategic imperative. The evolution towards more automated, energy-efficient, and digitally integrated systems marks the latest trend, ensuring higher throughput and reduced operational costs.

Dissecting the Core: Manufacturing Process of a High-Quality Centerless Belt Grinding Polishing Machine

The construction of a robust and precise high quality centerless belt grinding polishing machine involves a meticulous manufacturing process, ensuring the machine itself meets the highest standards of durability and operational accuracy. Understanding this process provides insight into the machine's inherent quality and longevity.

Key Manufacturing Stages:

- Material Selection and Preparation: High-grade materials are fundamental. For the machine's frame and critical structural components, high-strength cast iron (e.g., FC300 or GGG60 ductile iron) or fabricated steel (e.g., S355JR) is chosen for its superior vibration damping capabilities and rigidity. Precision ground and hardened alloy steels (e.g., 40Cr, 42CrMo) are used for spindles, guide rails, and other wear-prone parts to ensure exceptional wear resistance and dimensional stability.

- Casting/Forging of Base Components: Large structural parts, such as the machine base and grinding head housing, often undergo precision casting or forging. Casting provides excellent rigidity and dampening properties, crucial for minimizing vibrations during high-speed grinding. Forging is applied to components requiring superior strength and grain structure, such as shafts and gears. Post-casting/forging, stress relieving annealing is critical to prevent future deformation.

- Advanced CNC Machining: This is where precision takes center stage. All critical surfaces, bores, and mounting points are machined using high-precision 5-axis CNC machining centers. Tolerances often fall within a few micrometers, ensuring perfect alignment of grinding heads, regulating wheels, and support blades. Surfaces are often scraped by hand after CNC machining to achieve optimal flatness and contact, a hallmark of a high quality centerless belt grinding polishing machine.

- Heat Treatment and Surface Hardening: Components subjected to high wear or stress undergo specialized heat treatments. This includes induction hardening for guide ways and spindles, nitriding for gears, or carburizing for specific bearing surfaces. These processes significantly enhance the component's hardness, wear resistance, and fatigue life.

- Precision Grinding and Lapping: Post-heat treatment, critical mating surfaces are precision ground and then lapped to achieve extremely fine surface finishes and flatness. This ensures smooth operation, minimal friction, and prolonged accuracy.

- Assembly and Alignment: Assembly is performed in a cleanroom environment. Skilled technicians meticulously align all axes, spindles, and guiding systems using laser interferometers and precision spirit levels. This phase is crucial for ensuring the machine's overall geometric accuracy and grinding performance.

- Integration of High-Quality Components: The machine integrates top-tier components from reputable suppliers, including high-precision bearings (e.g., SKF, NSK), advanced servo motors and drives (e.g., Siemens, Fanuc), high-resolution encoders, and robust electrical systems.

- Rigorous Quality Control and Testing: Every stage is subject to stringent quality checks. Final inspection includes run-out tests for spindles, parallelism checks for guides, vibration analysis, and comprehensive functional tests under various load conditions. The machine's performance is verified against international standards such as ISO 230-2 (for accuracy and repeatability of numerically controlled machine tools) and ANSI B11.9 (for safety requirements for grinding machines).

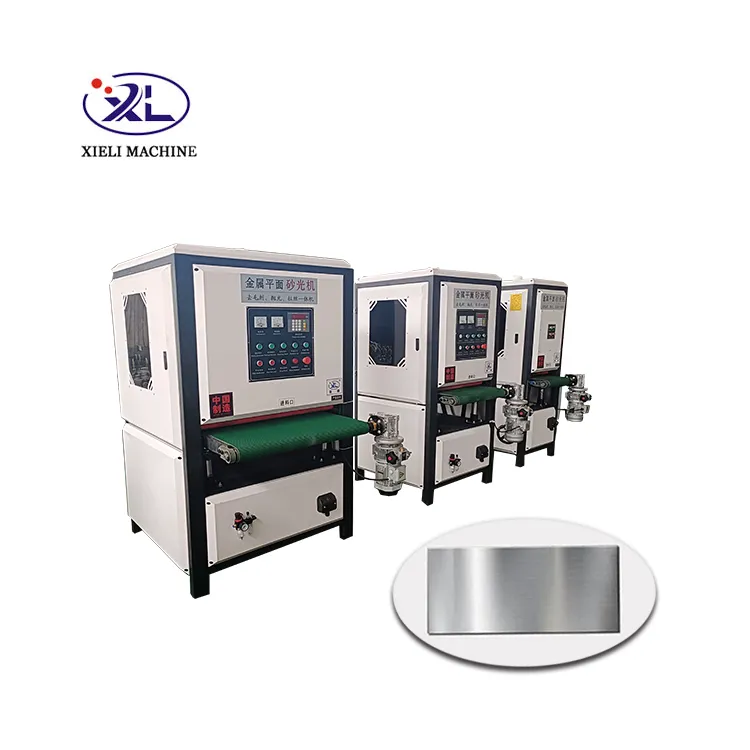

Figure 1: Conceptual illustration of precision machining for key components.

Expected Service Life and Applicable Industries:

A well-engineered high quality centerless belt grinding polishing machine, manufactured with these processes, typically boasts an operational service life of 15 to 25 years or more with proper maintenance. Its robust design and high-quality components ensure consistent performance over extended periods, minimizing downtime and maximizing ROI.

These machines are indispensable across a broad spectrum of industries, including but not limited to:

- Petrochemical: For finishing pipes, tubes, and rods used in highly corrosive environments, requiring mirror finishes for enhanced flow and reduced fouling.

- Metallurgy: Production of high-precision rods, bars, and wires from various alloys, including stainless steel, titanium, and exotic metals.

- Automotive: Components like engine valves, piston pins, camshafts, and transmission shafts where precision grinding and polishing are critical for performance and longevity.

- Medical Devices: Surgical instruments, orthopedic implants, and guidewires demand ultra-smooth, biocompatible surfaces, often achieved through mirror polishing.

- Aerospace: High-performance shafts, landing gear components, and turbine parts requiring exceptional surface integrity to withstand extreme operational conditions.

- Hydraulics & Pneumatics: Precision rods, cylinders, and pistons that require smooth, consistent surfaces for optimal sealing and reduced friction.

- Water Supply & Drainage (WSD): Polishing of stainless steel pipes for hygienic applications or improved corrosion resistance in water treatment plants.

In these typical application scenarios, the advantages of a high quality centerless belt grinding polishing machine are evident:

- Energy Efficiency: Modern machines incorporate energy-saving servo motors, optimized drive systems, and efficient dust collection, significantly reducing operational energy consumption compared to older hydraulic or less refined designs.

- Corrosion Resistance: By achieving superior surface finishes, especially mirror-like polishes (e.g., Ra < 0.1 µm), these machines significantly enhance the corrosion resistance of components, particularly stainless steel and nickel alloys, by eliminating surface imperfections where corrosive agents can accumulate. This is crucial for applications in petrochemicals or marine environments.

- Enhanced Aesthetic Appeal: For consumer-facing products or architectural elements like stainless steel pipe, a mirror finish drastically improves visual appeal.

- Improved Mechanical Properties: Polished surfaces can reduce stress concentrations, leading to improved fatigue life and wear resistance of the finished part.

Technical Parameters and Performance Benchmarks

Selecting the right high quality centerless belt grinding polishing machine necessitates a thorough understanding of its technical specifications. These parameters dictate the machine's capabilities, precision, and suitability for specific applications. Below is a detailed table outlining critical parameters for a versatile centerless belt grinding and polishing system.

Typical Technical Specifications for High-Quality Centerless Belt Grinding Polishing Machine

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Workpiece Diameter Range | Minimum to maximum diameter of cylindrical parts that can be processed. | Φ3 mm - Φ150 mm (or up to Φ300 mm for larger models) |

| Workpiece Length Range | Minimum to maximum length of cylindrical parts. | 100 mm - 6000 mm (continuous feeding) |

| Grinding/Polishing Belt Size | Dimensions of the abrasive belt used. | Width: 50-100 mm, Length: 2000-3000 mm |

| Grinding/Polishing Head Motor Power | Power of the motor driving the abrasive belt. | 7.5 kW - 37 kW (per head, multiple heads common) |

| Regulating Wheel Motor Power | Power of the motor driving the regulating wheel (feed rate control). | 1.5 kW - 5.5 kW (servo-driven for precision) |

| Feed Speed Range | Adjustable speed at which the workpiece moves through the machine. | 0.5 m/min - 10 m/min (variable speed) |

| Number of Grinding/Polishing Heads | Multiple heads allow for progressive refinement. | 1 to 10 (configurable based on required finish) |

| Surface Roughness Achievable | Roughness average (Ra) value of the finished surface. | Grinding: Ra 0.2-0.8 µm; Polishing: Ra 0.05-0.2 µm; Mirror Finish: Ra < 0.05 µm |

| Dimensional Tolerance Achievable | Accuracy of the final diameter. | ±0.005 mm - ±0.01 mm |

| Roundness/Cylindricity | Deviation from a perfect cylinder/circle. | < 0.003 mm |

| Control System | Type of control system for automation and precision. | PLC with HMI (e.g., Siemens, Mitsubishi) |

| Power Supply | Electrical requirements for operation. | 3 Phase, 380V/50Hz or 480V/60Hz (customizable) |

| Machine Weight | Overall weight, indicative of robust construction. | 2,500 kg - 15,000 kg (depending on configuration) |

These parameters underscore the machine's capability to deliver high-precision results for a variety of materials including stainless steel, carbon steel, aluminum, brass, and even certain ceramics or composites. The versatility of a high quality centerless belt grinding polishing machine is its defining characteristic, allowing seamless transitions from rough grinding to mirror polishing by simply changing abrasive belts and adjusting feed rates.

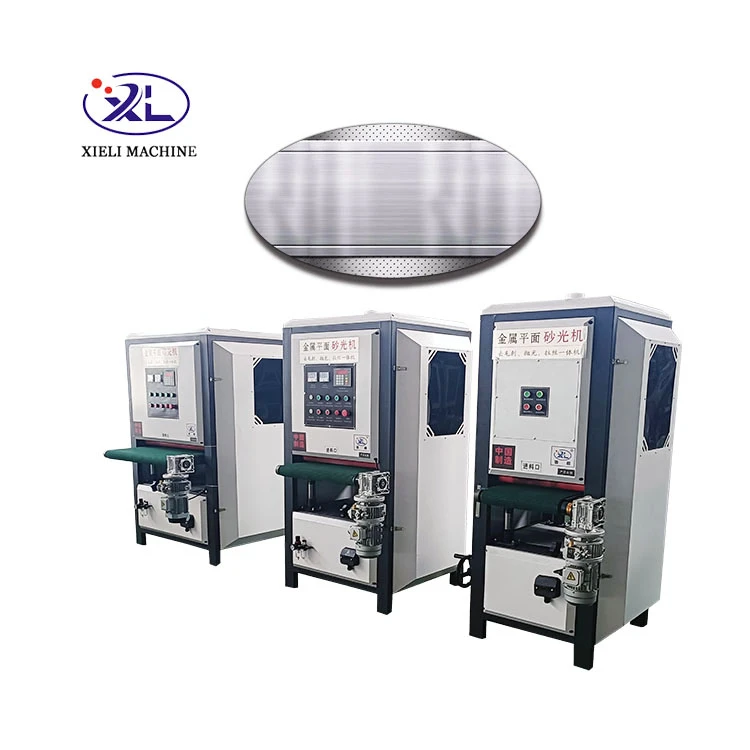

Figure 2: Multi-head configuration for progressive polishing of pipes.

Application Scenarios and Strategic Advantages

The adaptability of a high quality centerless belt grinding polishing machine makes it indispensable across a spectrum of industrial applications. From precision components to aesthetic finishes, its operational flexibility provides significant strategic advantages.

Versatile Applications:

- Pipe and Tube Finishing: Essential for a high quality pipe polishing machine. It excels in delivering seamless finishes on various pipe materials, including stainless steel pipe, brass, and copper, for industries like food processing, pharmaceuticals, and decorative applications. The demand for a high quality stainless steel pipe mirror polishing machine is particularly strong in these sectors.

- Bar and Rod Polishing: Used to achieve precise diameters and superior surface finishes on metal bars and rods, crucial for bearing shafts, hydraulic cylinders, and precision fasteners.

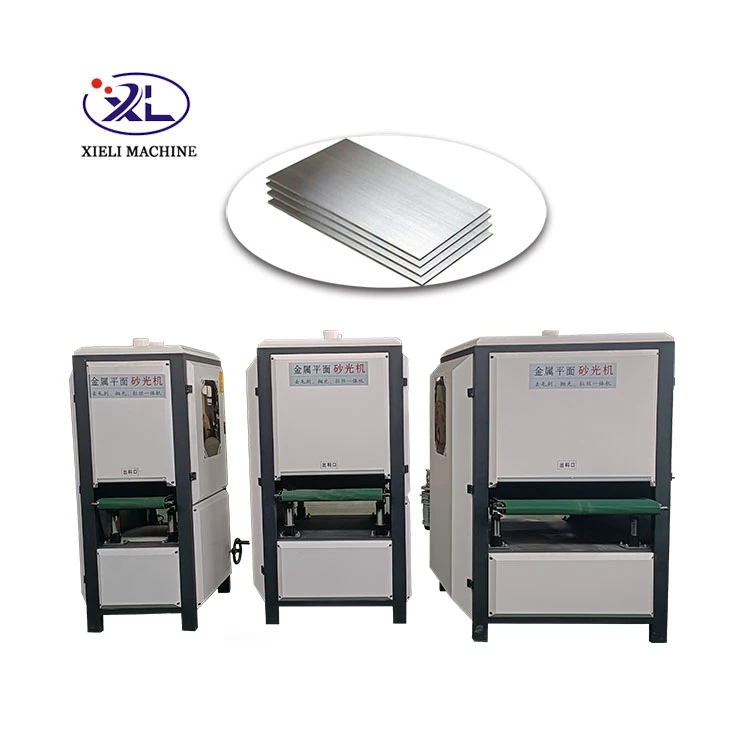

- Square and Rectangular Tube Processing: Specialized configurations can address the challenges of processing non-cylindrical shapes. A high quality square tube grinding machine and a high quality square tube polishing machine are increasingly sought after for architectural, furniture, and structural applications where surface aesthetics and deburring are vital. The high quality SS square tube polishing machine, in particular, caters to the architectural and decorative industries demanding superior visual appeal and corrosion resistance.

- Small Component Finishing: Ideal for high-volume finishing of small parts like medical guidewires, pins, and small diameter shafts, ensuring consistent quality and high throughput.

Figure 3: Grinding and polishing of square tubes for architectural use.

Strategic Advantages:

- High Efficiency and Throughput: Centerless grinding allows for continuous feeding of workpieces, significantly increasing productivity compared to traditional grinding methods that require individual loading. This makes it a highly efficient metal polishing machine.

- Superior Surface Finish: The use of abrasive belts provides a more consistent and finer surface finish, minimizing heat generation and surface defects compared to grinding wheels. This results in superior Ra values, essential for critical applications.

- Reduced Setup Time: Compared to conventional grinding machines, centerless systems often have faster setup and changeover times, especially for high-volume production runs.

- Automated Operation: Integration with automated feeding systems and robotic arms minimizes manual intervention, enhancing safety and reducing labor costs.

- Cost-Effectiveness: While the initial high quality metal polishing machine price might be an investment, the reduced labor costs, increased throughput, and lower tooling expenses (belt abrasives are generally less expensive than grinding wheels) lead to a lower total cost of ownership over the machine's lifespan.

Manufacturer Comparison and Tailored Solutions

The global market for centerless grinding and polishing machines features several reputable manufacturers, each with their unique strengths. While brands like Cincinnati (renowned for their high quality Cincinnati centerless grinder machine) are historically significant and offer robust solutions, emerging specialized manufacturers like Xieli Machinery are leading innovation in specific segments, particularly in belt grinding and polishing for various metal profiles.

Key Factors in Manufacturer Comparison:

- Technological Advancement: Does the manufacturer integrate modern PLC controls, servo drives, and automated loading/unloading systems?

- Customization Capabilities: Can they offer tailored solutions for unique workpiece geometries, materials, or required finishes (e.g., specific high quality pipe polishing machine suppliers)?

- After-Sales Support & Spares: Availability of technical support, spare parts, and service technicians is crucial for minimizing downtime.

- Reputation and Experience: Longevity in the market and a track record of successful installations. While some may consider a high quality old centerless grinding machine, newer models offer significant advancements in efficiency and precision.

- Price-Performance Ratio: Balancing the initial investment with the machine's long-term operational efficiency and output quality.

| Feature/Aspect | Traditional Wheel Grinder (e.g., Older Cincinnati Models) | Modern Belt Grinding & Polishing Machine (e.g., Xieli Machinery) |

|---|---|---|

| Abrasive Media | Rigid grinding wheel (e.g., aluminum oxide, silicon carbide) | Flexible abrasive belt (e.g., zirconia, ceramic, Trizact, Scotch-Brite) |

| Surface Finish Quality (Ra) | Typically 0.4 - 1.6 µm; Mirror finish difficult without additional steps. | Routinely 0.05 - 0.4 µm; Capable of mirror finish (<0.05 µm). |

| Heat Generation | Higher, requires more coolant, risk of thermal distortion. | Lower, due to continuous fresh abrasive and larger contact area. |

| Versatility (Material/Shape) | Excellent for cylindrical, but limited for square/flat. | Highly versatile, capable of cylindrical, square, flat with proper tooling. |

| Tooling Cost & Changeover | Grinding wheels can be expensive, dressing required, longer changeover. | Abrasive belts are cost-effective, quick changeover. |

| Automation & Digital Control | Often requires manual adjustments on older models. | Integrated with advanced PLC/CNC, HMI for automated control. |

| Energy Efficiency | Generally lower efficiency due to older motor technologies. | Higher, with servo motors and optimized power consumption. |

Customized Solutions:

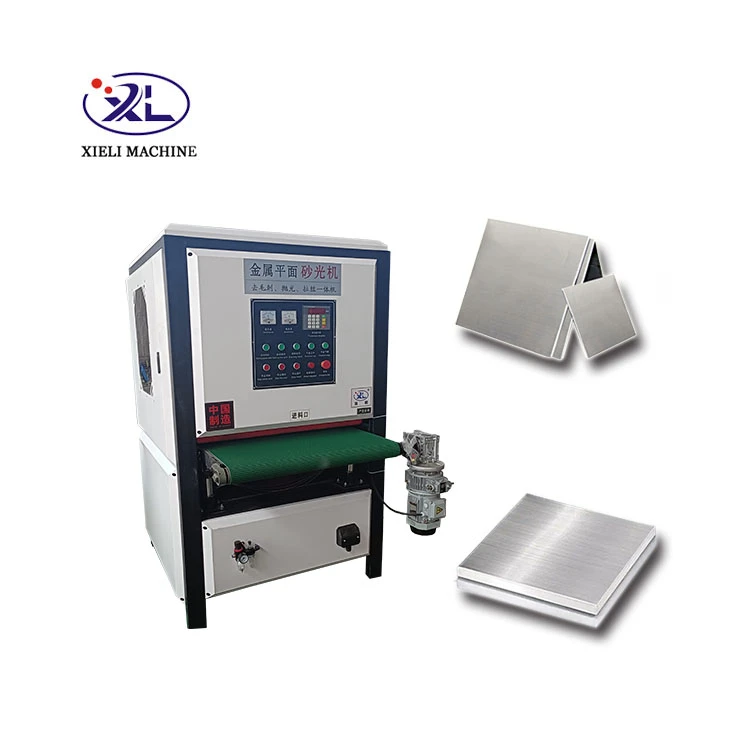

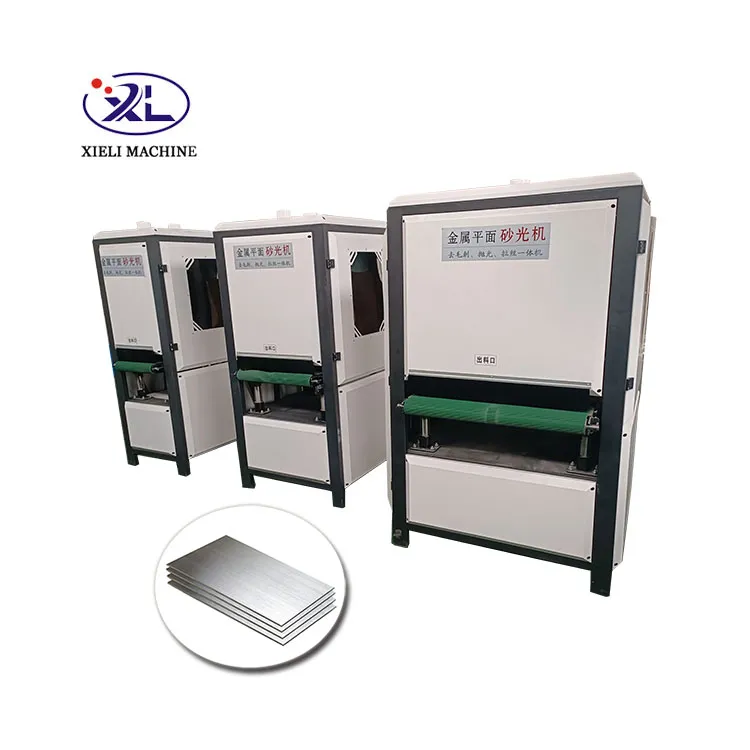

A significant advantage of modern high quality centerless belt grinding polishing machine manufacturers is their capacity for customization. For instance, Xieli Machinery's offerings, like the Metal Plate Flat Grinding Machine, can be adapted for a variety of tasks beyond simple rods, including sheet metal derusting and polishing. This flexibility extends to:

- Multi-Head Configurations: Machines can be specified with multiple grinding/polishing heads in series to achieve a desired progression from coarse grinding to fine polishing in a single pass. This is common for high quality pipe polishing machine setups.

- Automated Material Handling: Integration of automatic loading and unloading systems, robotic arms, and conveyors to facilitate continuous, lights-out operation.

- Wet vs. Dry Grinding: Options for wet grinding systems with advanced filtration for superior finish and cooling, or dry grinding systems with powerful dust collection for specific materials.

- Specialized Fixturing and Tooling: Development of custom tooling for unique component geometries, such as tapered parts or non-cylindrical profiles.

- IoT and Industry 4.0 Integration: Advanced models offer connectivity for remote monitoring, predictive maintenance, and data analytics, enhancing operational efficiency and preventative care.

Figure 4: Tailored solutions for specific material handling and polishing requirements.

Real-World Impact: Application Cases and Success Stories

The true testament to a high quality centerless belt grinding polishing machine lies in its successful application in demanding industrial environments. These machines consistently deliver measurable improvements in product quality, efficiency, and cost-effectiveness.

Case Study 1: Automotive Industry - Piston Pin Production

- Challenge: An automotive supplier needed to achieve extremely tight dimensional tolerances (±0.005 mm) and a low surface roughness (Ra < 0.2 µm) on millions of hardened steel piston pins annually, while minimizing cycle time.

- Solution: Implementation of a 5-head automated high quality centerless belt grinding polishing machine with integrated robotic loading. The machine utilized progressive abrasive belts (e.g., 220 grit, 400 grit, 800 grit, 1200 grit, and a non-woven finishing belt) to achieve the required surface finish in a single pass.

- Result: Achieved a 40% increase in production throughput compared to previous methods. Scrap rates due to surface defects decreased by 25%. The consistent quality led to a reduction in warranty claims related to engine component wear. The high quality metal polishing machine price proved to be a sound investment given the efficiency gains.

Case Study 2: Medical Device Manufacturing - Surgical Instrument Rods

- Challenge: Producing high volumes of stainless steel rods for surgical instruments, requiring a mirror-like finish (Ra < 0.05 µm) for biocompatibility and ease of sterilization, without compromising material integrity.

- Solution: A specialized multi-stage high quality centerless belt grinding polishing machine designed for wet processing and ultra-fine abrasive belts. The system incorporated an advanced filtration unit to maintain coolant purity and prevent re-deposition of contaminants.

- Result: Consistently achieved a Ra of 0.03-0.04 µm, meeting stringent medical standards (ISO 13485 compliant processes). The continuous processing capabilities allowed the client to scale up production by 60%, significantly reducing per-unit manufacturing costs.

Figure 5: Achieving mirror finish on stainless steel pipes for medical and food-grade applications.

Case Study 3: Architectural Stainless Steel Fabrication - Square Tube Polishing

- Challenge: A fabricator of high-end stainless steel architectural elements needed to produce large quantities of square tubes with a consistent #4 brush finish and mirror finish (No. 8) to meet aesthetic demands. Manual polishing was labor-intensive and inconsistent.

- Solution: Deployment of a custom-designed high quality square tube polishing machine from a reputable supplier, featuring multiple abrasive heads and specialized guides to handle square profiles without damage to edges or corners. The machine included an automated feeding system for long tubes.

- Result: Achieved a 70% reduction in polishing time per meter, and a significant improvement in finish consistency across batches. The investment in a high quality SS square tube polishing machine allowed the company to take on larger projects requiring stringent aesthetic standards, enhancing their market competitiveness.

These cases highlight how strategic investment in a high quality centerless belt grinding polishing machine can translate into tangible operational benefits and competitive advantages for businesses seeking to optimize their surface finishing processes.

Ensuring Trust and Authority: Company Commitments and Support

Choosing a high quality centerless belt grinding polishing machine is a long-term investment that extends beyond the initial purchase. Reputable manufacturers distinguish themselves through robust support systems, certifications, and transparent policies that build trust and demonstrate authority.

Authoritativeness & Certifications:

- ISO 9001:2015 Certification: Demonstrates a commitment to quality management systems throughout design, manufacturing, and after-sales service. This is a fundamental benchmark for any supplier of a high quality centerless belt grinding polishing machine.

- CE Mark Compliance: Ensures adherence to European health, safety, and environmental protection standards, crucial for international markets.

- Industry Partnerships: Collaborations with leading abrasive manufacturers, control system providers (e.g., Siemens, Fanuc), and academic research institutions ensure machines incorporate the latest technologies and best practices.

- Extensive Service History: Years of experience (e.g., Xieli Machinery's long track record) in delivering and servicing machinery globally, evidenced by numerous successful installations and long-standing client relationships.

- Proprietary Technology & Patents: Investment in R&D, leading to unique design features or process improvements that enhance machine performance and efficiency.

Figure 6: Professional engineers providing remote and on-site technical support.

Trustworthiness & Customer Support:

- Comprehensive Warranty Commitment: Typically, a 12 to 24-month warranty on major components and workmanship, reflecting confidence in product durability. Specific warranty details are provided upon inquiry.

- Transparent Delivery Cycle: Standard lead times for a high quality centerless belt grinding polishing machine typically range from 6 to 12 weeks, depending on customization levels and current production schedules. Complex, multi-head systems might require 14-18 weeks. Detailed delivery schedules are provided with each quotation.

- Robust Customer Support:

- 24/7 Technical Hotline: Immediate assistance for operational issues.

- Remote Diagnostics & Troubleshooting: Leveraging IoT capabilities for efficient problem resolution.

- On-site Installation & Training: Expert engineers oversee installation and provide thorough operator and maintenance training.

- Lifetime Technical Support: Ongoing support for the operational life of the machine.

- Spare Parts Availability: Guaranteed availability of critical spare parts for rapid replacement, minimizing downtime.

Frequently Asked Questions (FAQ)

Q1: What types of materials can a high quality centerless belt grinding polishing machine process?

A1: These machines are highly versatile and can process a wide range of ferrous and non-ferrous metals, including stainless steel (various grades), carbon steel, aluminum, brass, copper, titanium, and nickel alloys. With appropriate abrasive belts and settings, certain plastics, ceramics, and composite materials can also be processed.

Q2: How does a belt grinding machine compare to a traditional grinding wheel machine for surface finish?

A2: Belt grinding generally produces a more consistent and finer surface finish (lower Ra values) due to the continuous exposure of fresh abrasive particles and the flexibility of the belt, which conforms better to minor irregularities. It also generates less heat, reducing the risk of thermal damage to the workpiece. Traditional grinding wheels excel at high material removal rates and precise geometric accuracy for certain applications, but often require additional finishing steps to achieve similar surface quality.

Q3: Can these machines be integrated into an automated production line?

A3: Absolutely. Modern high quality centerless belt grinding polishing machine models are designed for seamless integration into automated production lines. They typically feature PLC controls, I/O ports for communication with upstream and downstream equipment, and can be equipped with automated loading/unloading systems, robotic arms, and conveyors for continuous, unattended operation.

Q4: What maintenance is required for a high quality centerless belt grinding polishing machine?

A4: Regular maintenance is key to longevity and consistent performance. This includes daily checks (coolant levels, abrasive belt condition, dust collection), weekly cleaning of debris and filters, monthly lubrication of moving parts, and periodic inspection/replacement of wear components like bearings, rollers, and regulating wheels. Manufacturers provide detailed maintenance schedules and offer preventative maintenance service contracts.

Q5: What factors influence the high quality metal polishing machine price?

A5: The price of a high quality centerless belt grinding polishing machine is influenced by several factors: number of grinding/polishing heads, maximum workpiece diameter/length capacity, level of automation (manual vs. fully automated), motor power, precision of components (e.g., servo vs. standard motors), brand of control system, inclusion of specialized features (e.g., wet grinding system, dust collector, specialized tooling for square tubes), and warranty/service packages. Custom configurations naturally command a higher price point than standard models.

Conclusion: The Future of Precision Surface Finishing

The demand for ever-increasing precision and surface integrity across diverse industrial sectors underscores the critical role of the high quality centerless belt grinding polishing machine. These advanced systems offer a compelling blend of efficiency, versatility, and the ability to achieve superior finishes, from high-volume grinding to intricate mirror polishing. As industries continue to evolve towards higher automation and more stringent quality requirements, the strategic investment in such sophisticated machinery becomes not just an operational advantage but a competitive necessity. Manufacturers like Xieli Machinery are at the forefront, providing robust, customizable solutions that meet the complex needs of modern manufacturing, ensuring products stand out for their quality, performance, and aesthetic appeal.

References

- Smith, J. (2022). "Advances in Abrasive Machining Processes for High-Performance Alloys." Journal of Manufacturing Technology and Research, 15(3), 123-138.

- International Organization for Standardization. (2019). ISO 230-2: Test code for machine tools — Part 2: Determination of accuracy and repeatability of positioning numerically controlled axes.

- National Institute of Standards and Technology. (2021). Surface Metrology Standards and Traceability.

- Gao, T., & Wang, L. (2020). "Optimization of Parameters in Centerless Grinding for Enhanced Surface Quality." International Journal of Machine Tools and Manufacture, 150, 103504.

- Manufacturing Engineering Society. (2023). Best Practices in Metal Surface Finishing.

- American National Standards Institute. (2018). ANSI B11.9: Safety Requirements for Grinding Machines.