Exploring OEM Tube Polishing Machines Enhancing Efficiency and Quality in Manufacturing

In the world of manufacturing, precision and quality are paramount, especially when it comes to specific components like tubes. OEM (Original Equipment Manufacturer) tube polishing machines are designed to meet these needs by providing efficient, consistent, and high-quality polishing solutions for various industries, including automotive, aerospace, and medical equipment manufacturing. This article explores the significance of OEM tube polishing machines and how they contribute to better production outcomes.

The Importance of Tube Polishing

Tube polishing is a crucial step in the production process, enhancing not only the aesthetic appeal but also the functional performance of the tubes. Polished tubes exhibit improved corrosion resistance, reduced friction during use, and enhanced cleanliness, which is vital in applications such as food processing and medical devices. In this context, OEM tube polishing machines are specialized tools that ensure uniform polishing across all surfaces, thereby maintaining high standards of quality.

Key Features of OEM Tube Polishing Machines

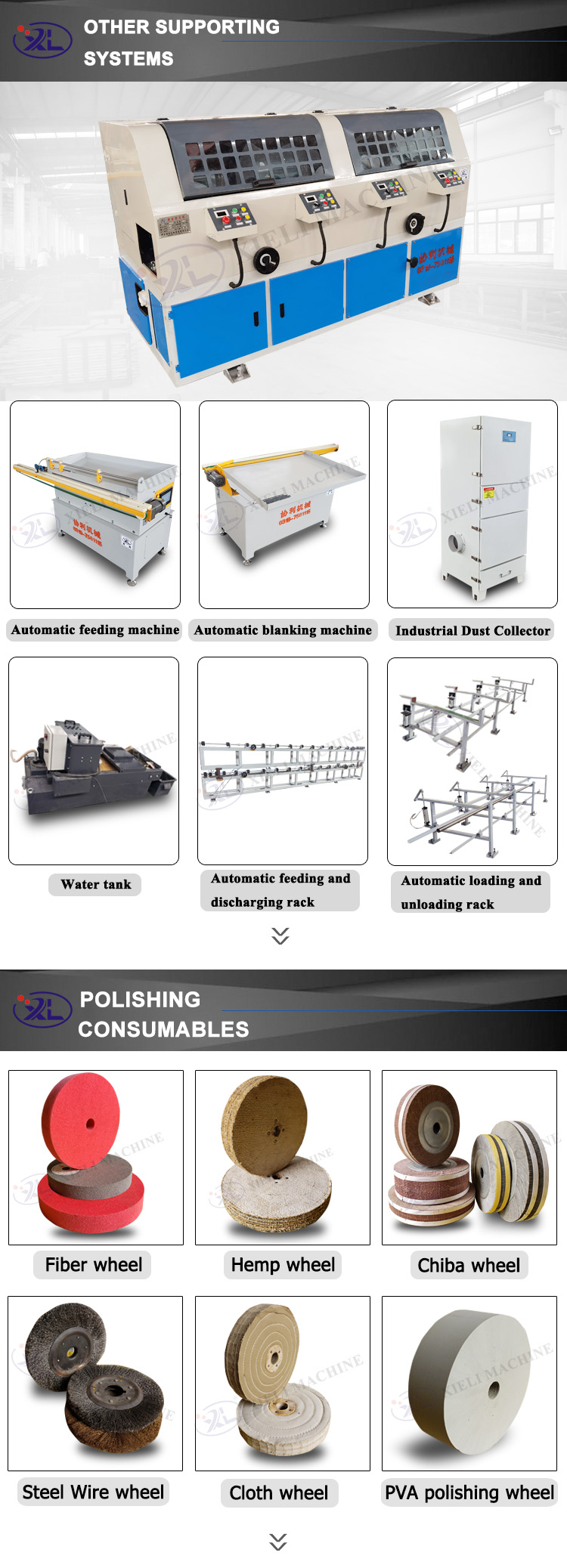

OEM tube polishing machines come equipped with various features designed to streamline the polishing process. Some of the key attributes include

1. Automated Processes Many OEM machines are fully automated, increasing productivity and reducing manual labor. Automation minimizes the risk of human error and ensures that each tube is polished to the same high standard, enhancing overall throughput.

2. Adjustable Settings These machines often allow users to adjust polishing speeds, pressure, and angle to suit different tube materials and desired finishes. This flexibility ensures that manufacturers can tailor the process to meet their specific needs, accommodating a wide range of tube sizes and shapes.

oem tube polishing machine

3. High-Quality Abrasives The best OEM tube polishing machines utilize advanced abrasive materials that are effective in removing surface imperfections while maintaining the integrity of the tube. This results in a flawless finish that meets industry standards.

4. Compact and Ergonomic Design Many machines are designed to save floor space in manufacturing settings, and ergonomic designs make them user-friendly, further enhancing productivity.

Advantages of Using OEM Tube Polishing Machines

The use of OEM tube polishing machines offers several advantages. Firstly, they significantly reduce polishing time compared to manual methods, allowing for quicker turnaround and increased production capacity. Secondly, the consistency of the polishing process guarantees that every tube meets the required specifications, thereby reducing waste and the need for rework.

Moreover, utilizing OEM machines can lead to cost savings in the long run. By improving efficiency and quality, manufacturers can decrease downtime and increase profitability. Additionally, these machines often have lower maintenance costs compared to traditional polishing methods, making them more economical over time.

Conclusion

In conclusion, OEM tube polishing machines play a vital role in modern manufacturing processes, particularly for industries that demand exceptional quality and precision. With their advanced features and numerous advantages, investing in these machines can enhance production efficiency, improve product quality, and ultimately, provide manufacturers with a competitive edge in the market. As industries continue to evolve, the reliance on high-performance tools like OEM tube polishing machines will only grow, paving the way for innovations in manufacturing excellence.