The Role of Centerless Grinder Operators in Exporting Precision Machinery

The manufacturing industry has always been pivotal in driving economic growth, with precision machinery playing a critical role in this sector. Among the various types of machinery utilized for manufacturing operations, centerless grinders are essential for achieving high precision in metalworking. As production methods have evolved, so has the need for skilled operators who can efficiently manage these machines. Centerless grinder operators nowadays hold a significant position, especially when it comes to exporting machinery and components globally.

Understanding Centerless Grinding

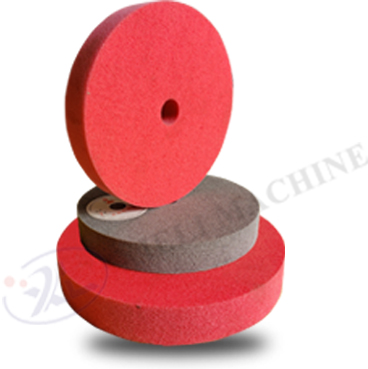

Before delving into the role of centerless grinder operators, it is essential to understand the mechanics of centerless grinding. This technique involves the removal of material from the outer diameter of a workpiece, which is held in place by a regulating wheel and a grinding wheel. The centerless grinding process is distinct because it does not require the workpiece to be mounted between centers, thus offering several advantages, including improved productivity and flexibility in the manufacturing process.

The Vital Role of Operators

Centerless grinder operators are responsible for setting up, operating, and maintaining these intricate machines. Their duties include adjusting the alignment of the grinding wheels, selecting appropriate speeds and feeds, monitoring machine performance, and conducting routine inspections to ensure the quality of the finished product. The accuracy and efficiency with which the operators execute these tasks are crucial in determining both the quality of the components produced and the overall operational efficiency of the manufacturing process.

Skills and Expertise Required

To become a proficient centerless grinder operator, one must possess a blend of technical skills and practical experience. Operators must have a thorough understanding of the machine's operational mechanics, as well as knowledge of the materials being processed. This knowledge enables them to make informed decisions about adjusting machine settings and diagnosing potential issues that may arise during operation.

centerless grinder operator exporter

In addition to technical skills, attention to detail is paramount in this role. The components produced through centerless grinding often require tolerances of just a few microns, making precision absolutely essential. Operators must be well-versed in the use of measuring instruments such as calipers and micrometers to ensure adherence to specifications.

Global Export Implications

The importance of skilled centerless grinder operators extends beyond the factory floor; it has significant implications for the global export market. With industries increasingly relying on precision-engineered components, the demand for high-quality, accurately manufactured parts has surged. Skilled operators are not only responsible for producing these components but also play an integral role in meeting the international quality standards required for export.

Countries focusing on manufacturing and exporting precision machinery, like Germany, Japan, and the United States, heavily invest in training and developing their workforce. As a result, they're equipped with technicians who can operate advanced centerless grinding machinery, ensuring that their products are competitive in the global market.

Future Trends and Opportunities

The future looks promising for centerless grinder operators as technological advancements continue to shape the industry. Automation and digitalization are paving the way for enhanced efficiency and precision in manufacturing processes. Operators skilled in programming and maintaining these advanced systems will be in high demand.

In conclusion, centerless grinder operators are vital to the precision manufacturing sector, particularly in the context of global exports. Their expertise ensures that high-quality products meet the stringent requirements of international markets. As technology evolves, continuous training and adaptation will be essential for these operators to maintain their crucial role in manufacturing's future landscape.