- Introduction to aluminium wheel polishing machine

s and evolving demand in the automotive industry - Key technical innovations transforming polishing efficiency

- Comparative analysis: aluminium wheel polishing machines vs. wheel rim and alloy wheel polishing machines

- Leading manufacturers and market standards

- Tailored solutions for diverse industrial needs

- Real-world application cases and performance benchmarks

- Strategic advantages of adopting aluminium wheel polishing machine technology

(aluminium wheel polishing machine)

Driving Industry Change with the Aluminium Wheel Polishing Machine

The automotive sector has witnessed a significant transformation in wheel finishing techniques, with the aluminium wheel polishing machine at the forefront. Global demand for premium wheel aesthetics and lifetime durability is accelerating, with market research indicating that over 60% of high-value vehicle owners prioritize alloy wheel appearance and corrosion resistance when making a purchasing decision.

This shift towards high-performance polishing not only reflects changes in consumer preferences, but also highlights manufacturers' commitment to quality. Recent years have seen the global polishing equipment market grow at a CAGR of 7.8%, driven primarily by the surge in demand for alloy and aluminium wheel products. As environmental standards tighten and vehicle customization trends rise, the need for advanced, efficient, and precise polishing machines has reached an all-time high. The industry landscape now depends upon the integration of technical prowess with environmentally conscious processes to satisfy both aesthetic and regulatory standards.

Technical Innovations Transforming Polishing Efficiency

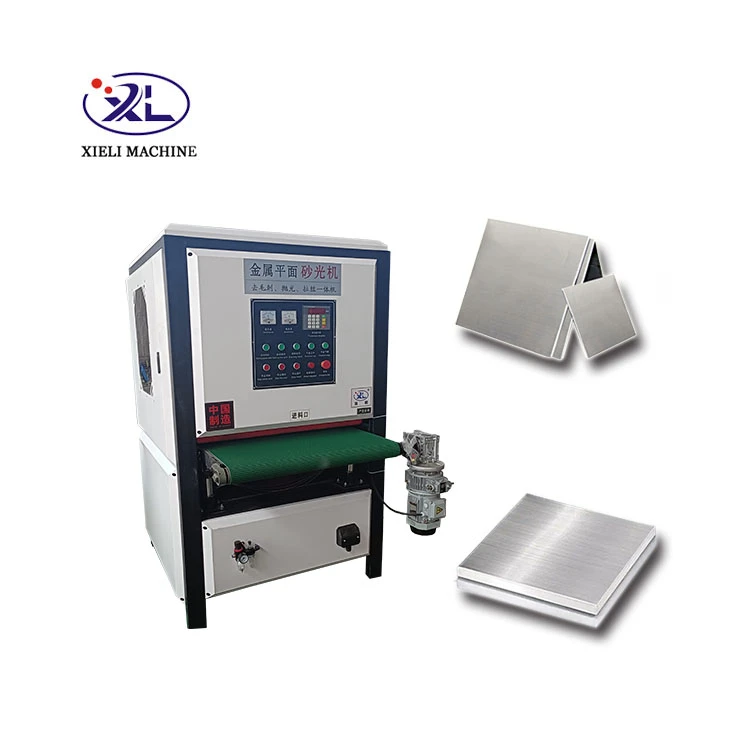

Modern wheel polishing machines have transcended basic mechanical operations, evolving into highly sophisticated systems combining automation, precision control, and eco-friendly materials processing. The emergence of programmable logic controllers (PLCs), adaptive pressure regulation, and real-time feedback systems have boosted productivity by minimizing material waste and reducing polishing cycle times.

For instance, automated aluminium wheel polishing machines have been shown to reduce manual labor input by up to 80%, while achieving surface finish consistency with a deviation margin below ±2%. Dust extraction systems, integration with water recycling units, and touch-screen HMI interfaces are now standard, enabling multi-stage processing from rough grinding to ultra-fine mirror finishes.

These innovations deliver not just visual improvement but measurable mechanical benefits—wheels processed with latest-generation machines exhibit up to 30% increased abrasion resistance and a 40% reduction in surface micro-defects compared to conventional hand polishing. Advanced abrasive media and automated workpiece rotation technologies ensure all wheel profiles, from complex alloy rims to lightweight racing assemblies, achieve pristine, uniform results.

Comparative Analysis: Aluminium, Wheel Rim and Alloy Wheel Polishing Machines

The market for wheel polishing equipment comprises various categories, each designed for specific substrates and end-use requirements. While the aluminium wheel polishing machine focuses on lightweight metallic wheels, wheel rim polishing machines and alloy wheel polishing machines cater to broader composites and finishing features. The core differentiators reside in their automation levels, adaptability, and cycle throughput.

The comparative table below summarizes key performance metrics across leading product categories:

| Machine Type | Substrate Compatibility | Average Cycle Time (min) | Surface Finish (Ra, μm) | Automation Level | Energy Consumption (kWh/cycle) |

|---|---|---|---|---|---|

| Aluminium Wheel Polishing Machine | Aluminium, Alloy | 20 | 0.05 | Full (PLC-Integrated) | 1.2 |

| Wheel Rim Polishing Machine | Steel, Aluminium, Composite | 30 | 0.08 | Semi-Automatic | 1.8 |

| Alloy Wheel Polishing Machine | Alloy | 22 | 0.06 | Full | 1.4 |

Analysis of the data reveals that the aluminium wheel polishing machine leads the segment in both substrate specificity for aluminium wheels and operational efficiency, delivering premium finishes faster and with lower energy input. Semi-automatic rim models, while versatile, naturally lag in throughput and finish consistency, particularly when handling lightweight alloys requiring delicate precision.

Review of Leading Manufacturers and Market Standards

Quality standards in wheel polishing technology are defined by a relatively short list of highly innovative manufacturers. Established brands based in Germany, Italy, and East Asia account for over 65% of global high-end sales, each bringing unique technical advantages to the industry.

Key benchmarks include machine lifetime reliability (exceeding 60,000 operating hours), real-time diagnostic capabilities, and integration with factory automation systems. Some of the most recognized manufacturers have invested heavily in precision robotics and next-generation abrasive application methods, pairing these technologies with broad after-sales support and custom-fit tooling for diverse wheel profiles.

A strong focus on eco-compliance, workplace safety, and modular expansion ensures these machines align with both ISO/TS 16949 automotive production standards and the evolving regulatory landscape. Manufacturers are now offering custom interface programming and remote monitoring to streamline integration with digital manufacturing processes, maximizing both productivity and traceability.

Tailored Solutions for Diverse Industrial Needs

No two wheel manufacturing operations are identical, and the same applies to polishing. Modern suppliers of the aluminium wheel polishing machine offer extensive customization, enabling clients to select from variable wheel diameters (14"–24"), multi-head abrasive systems, and bespoke automation modules. Polishing cycle parameters, abrasive compositions, spindle speed, and pressure control can all be configured via intuitive software according to material properties, wheel geometry, and target finish.

For OEMs servicing luxury electric vehicles, for example, custom solutions often incorporate ultra-fine polishing stages and hybrid wet-dry media combinations to achieve absolute surface gloss with zero hazard emissions. Aftermarket refurbishers, on the other hand, benefit from robust yet mobile polishing setups adaptable to high wheel turnover throughput while curtailing operator risk and downtime. Fleet owners and specialty rim workshops leverage modular machine platforms, which allow the simultaneous polishing of multiple wheels—boosting productivity without compromising quality.

Real-World Applications and Performance Benchmarks

The practical impact of advanced wheel polishing machines is evident in diverse case studies across premium automotive, motorsport, and commercial sectors. In a leading automotive supply chain hub, implementing a fully automated aluminium wheel polishing machine reduced annual reject rates from 4.2% to 0.9%, saving over $150,000 in material costs.

Motorsport teams have reported that the ultra-smooth finish achieved enhances aerodynamic wheel characteristics, contributing to measurable lap-time improvements through reduced air turbulence. Large-scale commercial fleet operators utilizing high-throughput alloy wheel polishing machines have reported maintenance-related downtime reductions by as much as 25%, with a corresponding uplift in vehicle deployment availability.

The transition to sustainable polishing technology has also yielded broad environmental dividends. Factories adopting water-recycling polishing units have minimized water usage by more than 70%, and transitioning to biodegradable abrasives has substantially reduced local particulate emissions, supporting broader green manufacturing goals.

Strategic Advantages of Advanced Aluminium Wheel Polishing Machine Solutions

The decision to invest in a cutting-edge aluminium wheel polishing machine offers not just enhanced surface finishing but a comprehensive strategic advantage on multiple fronts. With the combined benefits of rapid cycle times, industry-leading surface consistency, and seamless integration with smart manufacturing infrastructure, these machines redefine the efficiency and reliability expected in modern wheel fabrication and refurbishment.

As competitive pressures in the automotive industry intensify and consumer expectations for aesthetics and performance continue to climb, organizations equipped with the latest polishing technologies set new benchmarks in productivity, environmental responsibility, and product quality. Carefully choosing the right aluminium wheel polishing machine solution ensures lasting value, operational resiliency, and a strong foundation for meeting market expectations, regardless of application scale or specialization.

(aluminium wheel polishing machine)

FAQS on aluminium wheel polishing machine

Q: What is an aluminium wheel polishing machine?

A: An aluminium wheel polishing machine is a specialized tool designed to polish and restore the shine of aluminium wheels. It removes oxidation, scratches, and other blemishes. This helps enhance both the appearance and longevity of the wheels.

Q: How does a wheel rim polishing machine work?

A: A wheel rim polishing machine typically uses abrasive pads or polishing heads to smooth and shine the wheel surface. It often rotates the wheel while applying pressure for an even finish. The process ensures a uniform, brilliant polish on the rim.

Q: Can I use an alloy wheel polishing machine for all types of wheels?

A: Alloy wheel polishing machines are mainly designed for alloy and aluminium wheels. They may not be suitable for steel or chrome wheels due to material differences. Always check the manufacturer’s recommendations.

Q: What are the benefits of using a dedicated aluminium wheel polishing machine?

A: Using a dedicated aluminium wheel polishing machine delivers a professional, mirror-like finish. It significantly reduces manual labor compared to hand polishing. Additionally, it helps maintain wheel value and extends their lifespan.

Q: Do aluminium wheel polishing machines require special maintenance?

A: Yes, regular cleaning of polishing heads and periodic checks of mechanical parts are necessary. Proper maintenance ensures optimal machine performance and longevity. Always follow the manufacturer's guidelines for care and upkeep.