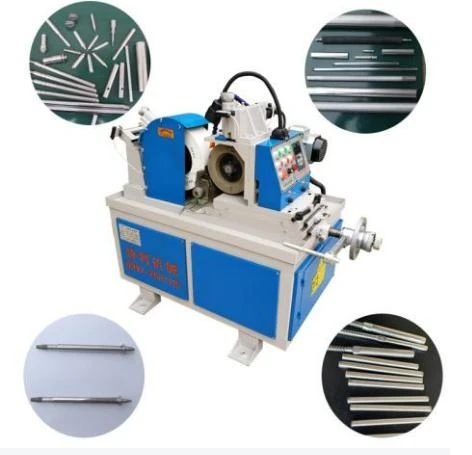

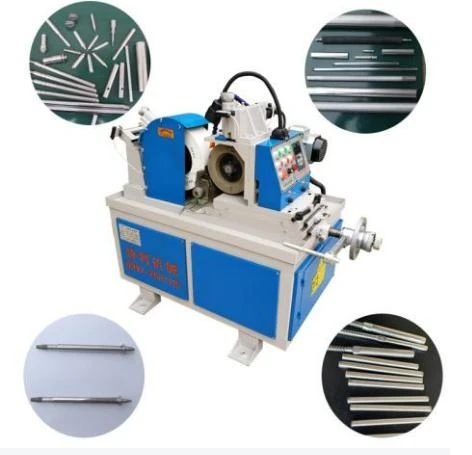

Centerless grinding, an innovative technique widely used across various industries, is redefining the way we perceive precision machining. At its core, centerless grinding is a machining process that involves multiple steps to achieve an astonishing level of accuracy. Unlike traditional grounded methods, this approach eliminates the need for a spindle or fixture since the workpiece is supported by a blade between two rotating wheels— a regulating wheel, and a grinding wheel.

This seamless method is invaluable when discussing surface grinders, a specific variety dedicated to producing exceptionally fine finishes. The synergy between centerless grinding and surface grinders presents several advantages, not just for manufacturing but for enhancing product quality and operational efficiency.

Beginning with its unparalleled efficiency, centerless grinding on a surface grinder significantly reduces the production time without compromising on quality. Manufacturers who adopt this method often report a noticeable increase in throughput—a critical competitive advantage in today's fast-paced industry. This efficiency stems from the elimination of time-consuming fixtures and setups; the workpiece is fed directly between the wheels, allowing continuous, uninterrupted processing.

Precision is another hallmark of centerless grinding. When integrated with surface grinders, manufacturers can produce components with minute tolerances that meet industry standards. This precision is primarily due to the self-centering nature of the process, which ensures consistent roundness and dimensions. As a result, applications demanding the utmost precision, such as automotive components or aeronautical parts, greatly benefit from this technology.

Furthermore, centerless grinding on surface grinders is incredibly versatile, capable of handling diverse materials including metals, plastics, and composites. This versatility expands the scope of application across multiple industries such as aerospace, electronics, automotive, and even medical devices. Given the broad spectrum of materials handled, it necessitates a deep understanding of the individual properties of each material to optimize the grinding process effectively.

Centerless grinding is also celebrated for its ability to enhance surface finishes. The integration with surface grinders allows for the achievement of finishes that are smooth, uniform, and free from blemishes. For industries where surface integrity is crucial—such as semiconductor or optical production—a superior finish contributes both to the aesthetic appeal and functional performance of the components.

centerless grinding on surface grinder quotes

Reflecting on product quality,

employing centerless grinding with surface grinders promotes consistency. The automated nature and reduced human intervention mean that each part produced is remarkably similar, mirroring the precision of its predecessor. Consistency not only signifies reliability but also aligns with rigorous industry compliances ensuring that the products meet every stipulated guideline required for safety and performance.

While the technical aspects are evidently monumental, the role of experienced technicians remains indispensable. Expertise in centerless grinding processes, coupled with familiarity with surface grinders, allows for optimization at every stage; from setup and operation to maintenance. Specialized training and field experience sharpen this expertise, bolstering credibility and authority in manufacturing circles.

Another consideration pivotal to the integration process is trustworthiness. Ensuring the grinding wheels, blades, and regulating wheels are from reputable manufacturers guarantees durability and performance fidelity over extended periods. Furthermore, maintaining a proactive maintenance schedule mitigates breakdown risks, cementing trust in the process's reliability.

The navigational aspects of implementing centerless grinding on surface grinders require comprehensive strategy formulation and meticulous process design. At the heart of this lies the objective of balancing efficiency with precision, a target achievable only through adept understanding and deployment.

Ultimately, the adoption of centerless grinding on surface grinders isn’t just about technological enhancement. It symbolizes a commitment to quality, precision, and continuous improvement—tenets that every forward-thinking manufacturer strives to achieve. Whether viewed through the lens of cost-efficiency, operational excellence, or quality assurance, centerless grinding stands as a transformative influence on modern manufacturing.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.