The Advantages of OEM Best CNC Centerless Grinders

In the ever-evolving world of manufacturing and machining, precision is paramount. The demand for high-quality machined components necessitates advanced technology and equipment. One of the key players in achieving this precision is the OEM best CNC centerless grinder. These machines have garnered a reputation for their ability to produce components with remarkable accuracy and efficiency. In this article, we will explore the advantages of utilizing OEM CNC centerless grinders in manufacturing processes.

Precision Engineering

One of the primary benefits of using OEM best CNC centerless grinders is their unparalleled precision. These machines operate on a principle that allows for tight tolerances and uniformity. By utilizing advanced CNC technology, they can continuously monitor and adjust the grinding process, resulting in components that meet even the most stringent specifications. This level of precision is essential in industries such as automotive, aerospace, and medical device manufacturing, where small variances could lead to significant issues.

Increased Efficiency

Efficiency is a critical factor in any manufacturing environment, and CNC centerless grinders excel in this area. The design of these machines allows for a continuous grinding operation, significantly reducing cycle times compared to traditional grinding methods. This continuous operation means that manufacturers can process a larger volume of parts in a shorter period, promoting higher productivity. Moreover, the integration of automation features in many OEM models further enhances efficiency, minimizing the need for manual intervention and reducing human error.

Versatility

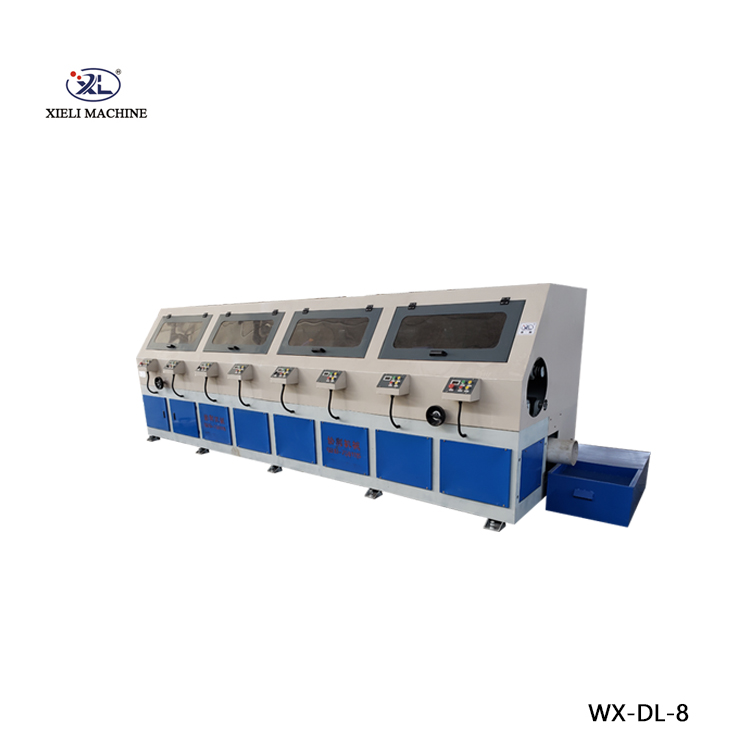

oem best cnc centerless grinder

OEM best CNC centerless grinders are incredibly versatile, capable of handling a wide variety of materials and part sizes. From small, intricate components to larger industrial parts, these machines can be configured to meet specific grinding needs. The adaptability of CNC technology allows manufacturers to easily switch between different processes or materials without the need for extensive setup changes. This flexibility makes CNC centerless grinders a valuable asset in any job shop or production floor.

Enhanced Surface Finish

Another significant advantage of using OEM CNC centerless grinders is the high-quality surface finish they can achieve. The grinding process is designed to remove material efficiently while minimizing the impact on the part's surface. As a result, manufacturers can produce components with a superior finish, which is essential in applications where aesthetics, corrosion resistance, or fatigue strength are critical. The ability to achieve exceptional surface quality without the need for additional finishing processes can lead to cost savings and faster delivery times.

Cost-Effectiveness

While the initial investment in OEM CNC centerless grinders may be higher than traditional grinding equipment, the long-term financial benefits are substantial. The combination of increased efficiency, reduced cycle times, and diminished waste translates to lower operational costs. Additionally, the durability and reliability of OEM machines mean that they require less maintenance and fewer replacements, further enhancing their cost-effectiveness over time.

Conclusion

In summary, the adoption of OEM best CNC centerless grinders in manufacturing processes provides numerous advantages that can significantly enhance productivity, precision, and overall quality. With their ability to deliver tight tolerances, improve efficiency, and achieve excellent surface finishes, these machines are indispensable in many industries. As manufacturers continue to seek ways to stay competitive in a global market, embracing advanced technologies like CNC centerless grinders will be crucial for success. Investing in such cutting-edge equipment not only uplifts production capabilities but also ensures that companies maintain high standards in the ever-demanding landscape of industrial manufacturing.