The China MLW100 Tube Polishing Machine Revolutionizing Metal Finishing

In the competitive landscape of manufacturing, the finishing process plays a pivotal role in enhancing the aesthetics and functionality of metal products. Among various finishing techniques, tube polishing stands out due to its ability to produce a smooth and shiny surface that not only enhances the visual appeal but also improves corrosion resistance. The China MLW100 Tube Polishing Machine is an innovative solution that is transforming the tube polishing industry.

The MLW100 is engineered with advanced technology to achieve high efficiency and precision in polishing metal tubes. It is particularly suitable for stainless steel, aluminum, and other metal materials, which are widely used in various industries including automotive, aerospace, and medical equipment manufacturing. One of the key features of the MLW100 is its ability to accommodate various tube diameters and lengths, making it a versatile choice for manufacturers dealing with multiple products.

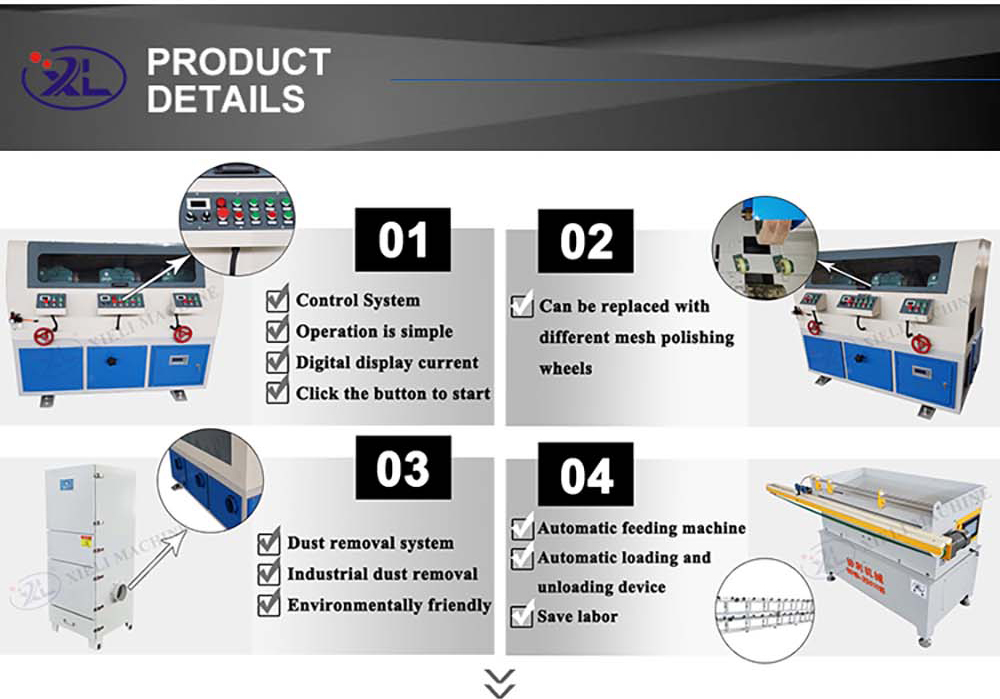

Design and Features

The design of the MLW100 is user-centric, ensuring ease of operation and maintenance. Its robust construction guarantees stability and durability, even in high-demand production environments. The machine is equipped with a powerful motor that drives the polishing belts, allowing for consistent and effective polishing results.

Additionally, the MLW100 incorporates an adjustable polishing speed feature, which enables operators to tailor the process according to the specific requirements of the material and desired finish

. This adaptability is crucial for manufacturers who need to meet varying customer specifications without compromising on quality.Another notable feature of the MLW100 is its safety mechanisms. The machine is designed with several safety measures, including emergency stop buttons and protective guards, ensuring a secure working environment for operators. Safety is paramount in any manufacturing setting, and the MLW100 addresses this concern effectively.

china mlw100 tube polishing machine

Efficiency and Cost-Effectiveness

The efficiency of the MLW100 translates into significant cost savings for manufacturers. Its quick setup time and high throughput allow businesses to increase their productivity without a proportional rise in labor costs. This efficiency is particularly important in a market that demands rapid delivery times alongside high-quality products.

Moreover, the MLW100 minimizes the waste of polishing materials, with its optimized design ensuring that the polishing belts wear evenly and last longer. This not only reduces the overall cost of operation but also contributes to sustainability practices by minimizing waste in the manufacturing process.

The Future of Tube Polishing

As industries continue to evolve, the demand for high-quality metal finishing processes will only increase. The China MLW100 Tube Polishing Machine is poised to meet this demand with its state-of-the-art technology and reliable performance. Manufacturers who adopt this machine will find themselves at the forefront of innovation in tube polishing, able to deliver superior products that meet and exceed customer expectations.

In conclusion, the MLW100 embodies the fusion of technology and practicality, making it an essential addition to modern manufacturing facilities. By investing in such advanced machinery, businesses can improve their operational efficiency, enhance product quality, and maintain a competitive edge in the market. As the landscape of manufacturing continues to change, tools like the China MLW100 will play a crucial role in shaping the future of metal finishing.