Centerless Grinder Training Elevating Skills for Precision Manufacturing

In the realm of precision manufacturing, centerless grinding stands out as a crucial process for shaping and finishing round parts. As industries demand higher tolerances and better surface finishes, the need for skilled operators becomes paramount. This is where centerless grinder training comes into play, providing professionals with the tools and knowledge required to excel in this specialized field.

Understanding Centerless Grinding

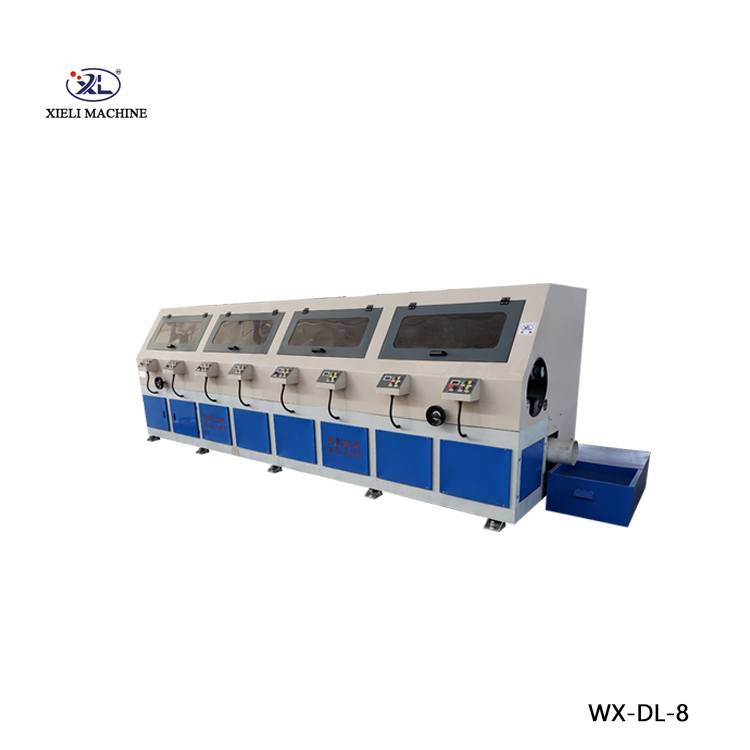

Centerless grinding is a method of removing material from a workpiece without the need for a fixed center, typically achieved by using two grinding wheels the regulating wheel and the grinding wheel. The workpiece is held in place by these wheels, which allow for continuous feeding without the need for clamping. This enables high production rates and ensures precise dimensions, making it essential for manufacturing components in automotive, aerospace, and various other industries.

Importance of Training

The intricacies of operating a centerless grinder are not to be underestimated. Operators must understand both the machinery and the materials they are working with. Training programs focus on various aspects, including machine setup, operational techniques, quality control, and troubleshooting common issues. Such comprehensive training equips operators with the skills to maintain optimal machinery performance and output quality.

Key Learning Areas

centerless grinder training exporter

1. Machine Setup Proper machine setup is critical for achieving desired tolerances. Training includes learning how to adjust wheel heights, angles, and the speed of the regulating wheel. Additionally, operators gain insights into selecting the right type of abrasive wheels based on the materials being processed.

2. Operational Techniques Effective grinding techniques vary based on workpiece material and desired finish. Trainees learn the importance of feed rates, wheel conditioning, and cooling methods to enhance the grinding process. Recognizing how these factors influence the quality of the finished product is crucial for any operator.

3. Quality Control Ensuring the quality of output is a fundamental aspect of centerless grinding. Training encompasses various measurement techniques and tools, enabling operators to inspect dimensions and surface finishes to meet industry standards. Awareness of how grinding variables affect the final output is also emphasized.

4. Troubleshooting Skills Even the most sophisticated equipment can encounter issues. Training programs prepare operators to identify and address common problems, from uneven wear on grinding wheels to misalignment of workpieces. This readiness ensures minimal downtime and maintains production efficiency.

Conclusion

Investing in centerless grinder training is not merely an operational necessity; it is a strategic move for companies aiming to stay competitive in today's demanding manufacturing landscape. Skilled operators who are well-versed in the latest techniques and practices will contribute significantly to product quality and efficiency. As the industry continues to evolve, ongoing training and development will be key to meeting new challenges and harnessing innovative technologies. By focusing on comprehensive training programs, businesses can cultivate a workforce capable of mastering the art of centerless grinding, ensuring precision and excellence in every component produced.