Pipe Grinding Machine Suppliers Ensuring Quality and Efficiency in Metal Fabrication

In the realm of metal fabrication, the importance of precision cannot be overstated, particularly when working with pipes. This is where pipe grinding machines come into play, providing an essential solution for businesses and manufacturers seeking to achieve high-quality surface finishes and dimensions on metal pipes. The role of reliable pipe grinding machine suppliers is crucial in ensuring that these machines meet industry standards and contribute to the overall efficiency of production processes.

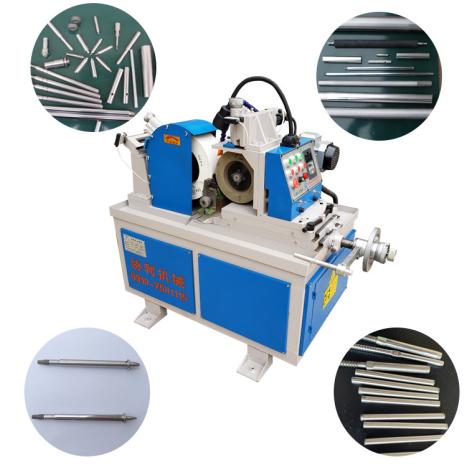

Pipe grinding machines are specialized tools designed to smooth out the surface of pipes, remove imperfections, and prepare them for further processing or finishing. These machines come in various designs, including belt grinders, angle grinders, and CNC grinding machines, each tailored to meet specific needs. A reputable supplier will offer a range of machinery options, allowing businesses to select the right equipment that suits their particular requirements, whether they are working with stainless steel, aluminum, or other materials.

When choosing a pipe grinding machine supplier, several factors should be considered. First and foremost, quality is paramount. Superior-quality machines not only perform better but also have longevity, minimizing the frequency of replacements and repairs. Suppliers who provide machines from well-known, trusted brands often assure buyers of both performance and durability. Additionally, it is vital to check if the supplier offers a warranty and after-sales support; this can greatly mitigate risks associated with machine failures during production.

pipe grinding machine supplier

Another critical aspect to consider is the level of customization the supplier offers. Each fabrication shop has unique operational needs, and a one-size-fits-all approach may not be the most effective. Quality suppliers typically work closely with their clients, providing tailored solutions that address specific grinding tasks. This could include modifications to machine setup or adding features to enhance functionality, such as automatic feeding mechanisms or advanced dust extraction systems.

Moreover, it is essential to evaluate the supplier's reputation in the industry. Reviewing customer testimonials and case studies can provide insight into the supplier’s track record and the level of satisfaction among their clients. A reliable supplier will have a history of successful partnerships with various industries, demonstrating their ability to deliver quality products consistently.

Additionally, the technological advancement of grinding machines has led to the emergence of CNC grinding machines, which offer enhanced precision and automation. These machines are particularly beneficial for mass production, as they reduce labor costs and minimize human error. Suppliers that stay ahead of technological trends ensure their clients have access to the latest innovations in pipe grinding.

In conclusion, when searching for a pipe grinding machine supplier, businesses should focus on quality, customization, reputation, and technological advancements. By partnering with the right supplier, manufacturers can improve their productivity and ensure the highest standards of quality in their pipe fabrication processes. As industries continue to evolve, the demand for effective and reliable pipe grinding solutions will only grow, making it vital for suppliers to equip their clients with the best machines and support possible.