The Benefits and Advancements of Centerless Belt Grinding Polishing Machines

In the realm of manufacturing and metalworking, maintaining product quality while optimizing production efficiency is a constant challenge. One critical solution that has emerged is the centerless belt grinding polishing machine. This innovative equipment combines grinding and polishing processes in a way that enhances both precision and productivity, making it an invaluable asset for industries that require high-quality surface finishes on metal parts.

Understanding Centerless Belt Grinding Polishing Machines

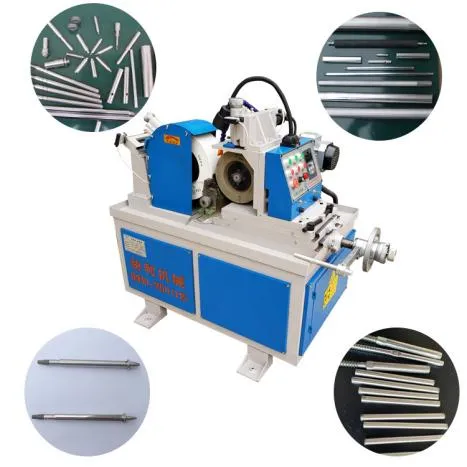

At its core, a centerless belt grinding polishing machine operates on the principle of using an abrasive belt to grind and polish the surface of metal workpieces. Unlike conventional grinding machines that hold the workpiece in a fixed position, centerless machines allow for continuous feeding of parts, facilitating uninterrupted processing. This not only accelerates production rates but also ensures uniformity in the surface finish of different components.

The design of centerless machines enables them to process materials of varying shapes and sizes. This versatility is particularly beneficial in industries such as automotive, aerospace, and medical manufacturing, where components may have different geometries but require similar surface finish criteria.

Key Advantages

1. Enhanced Efficiency Centerless grinding eliminates the need for multiple setups often required in traditional grinding methods. As a result, manufacturers can reduce cycle times and boost throughput, leading to cost savings and better resource utilization.

2. Superior Surface Finishing The use of a belt provides a smoother, finer finish compared to traditional grinding wheels. This is crucial in applications that demand a high-quality aesthetic finish, such as decorative metal parts and components used in high-visibility applications.

buy centerless belt grinding polishing machine

3. Flexibility and Adaptability Centerless belt grinding machines can be easily adjusted to accommodate different material types and thicknesses, allowing manufacturers to adapt to changing production needs without significant downtime.

4. Minimized Waste The precision of centerless processing means that less material is wasted during the grinding and polishing stages. Efficient material usage not only reduces costs but also aligns with modern sustainability practices in manufacturing.

5. Ease of Use Many modern centerless belt grinding polishing machines feature user-friendly controls and automation, making them easy to operate. This simplicity helps reduce the learning curve for new operators and minimizes the chances of operator error.

Technological Advancements

Over the past few years, the technology surrounding centerless belt grinding polishing machines has seen significant advancements. Innovations such as enhanced automation, integration with CNC technology, and improved abrasive materials have further propelled their efficiency and effectiveness. Modern machines can be equipped with sensors that monitor parameters like pressure, speed, and vibration, allowing for real-time adjustments that enhance consistency and reduce the risk of defects.

Moreover, the incorporation of software solutions for digital tracking and process optimization enables manufacturers to analyze performance data in real-time, leading to continuous improvement and maintenance planning.

Conclusion

In summary, the centerless belt grinding polishing machine is a powerful tool that is reshaping the landscape of manufacturing across various industries. Its ability to deliver high-quality surface finishes efficiently while minimizing waste positions it as a go-to solution for businesses looking to enhance their production capabilities. As technology continues to advance, these machines will only become more effective, making them a critical investment for any manufacturer committed to quality and productivity. Whether you are a small shop or a large-scale manufacturing plant, recognizing the advantages of centerless belt grinding polishing machines can be the key to staying competitive in today’s fast-paced market.