Wholesale Centerless Grinder Wheels A Comprehensive Overview

Centerless grinding is a vital machining process that is widely used in manufacturing industries for producing highly precise and uniform cylindrical parts. One of the key components that significantly influence the efficiency and effectiveness of this process is the grinding wheel. In this article, we will explore the importance of wholesale centerless grinder wheels, their types, benefits, and considerations for selection.

Understanding Centerless Grinding

Before diving into the specifics of grinding wheels, it’s essential to understand the centerless grinding process itself. Unlike traditional grinding methods where the workpiece is held between two centers, centerless grinding allows for the workpiece to be fed through the machine without the need for any holding mechanisms. This not only increases productivity but also enables the processing of multiple pieces simultaneously.

The Role of Grinding Wheels

Grinding wheels are crucial elements in the centerless grinding process, as they determine the quality of the surface finish, dimensional accuracy, and material removal rates of the workpieces. The wheels come in various sizes, shapes, and compositions, all tailored for different applications and materials. Understanding these variations is key for manufacturers aiming to achieve the best results.

Types of Grinding Wheels

1. Bond Types Grinding wheels can be categorized based on their bond types, which can be vitrified, resin, metal, or rubber. Each bond type offers unique advantages; for instance, vitrified wheels are known for their durability and strength, while resin wheels provide superior flexibility and are often used for tougher materials.

2. Abrasive Materials The choice of abrasive material is equally important. Common materials include aluminum oxide, silicon carbide, and cubic boron nitride (CBN). Aluminum oxide is suitable for general-purpose grinding, while CBN wheels are ideal for grinding hard materials like tool steel.

3. Wheel Geometry The geometric design of the grinding wheel also plays a significant role. The wheel's diameter, thickness, and shape should align with the specific application requirements to optimize performance and efficiency.

Benefits of Wholesale Purchasing

When it comes to sourcing centerless grinder wheels, purchasing in wholesale quantities can offer numerous benefits, including

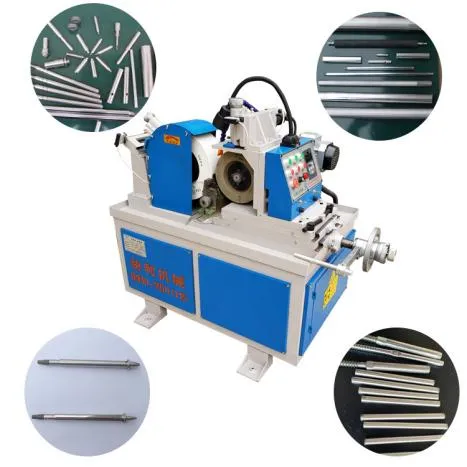

wholesale centerless grinder wheels

- Cost-Effectiveness Buying in bulk often leads to substantial savings on a per-unit basis, which can significantly reduce overall production costs

.- Consistent Supply Wholesale purchasing ensures a steady supply of grinding wheels, minimizing downtime and ensuring that production schedules remain uninterrupted.

- Custom Solutions Many wholesale suppliers are willing to work with manufacturers to develop custom grinding wheels tailored specifically to their needs, allowing for optimized grinding processes.

Considerations for Selection

When choosing wholesale centerless grinder wheels, several factors should be considered

1. Material Compatibility Ensure that the chosen wheels are suitable for the materials being processed to achieve the desired finish and accuracy.

2. Application Requirements Different applications may require specific wheel characteristics; for instance, high removal rates or finer finishes. Understanding these requirements will guide better selection.

3. Supplier Reliability Partner with reputable suppliers known for quality products and reliability. This can help avoid issues related to inferior wheels that may compromise workpiece quality.

4. Safety Standards Ensure that the grinding wheels conform to safety standards and regulations to minimize risks during operation.

Conclusion

Wholesale centerless grinder wheels are a fundamental aspect of the centerless grinding process, influencing efficiency, cost, and overall quality. By understanding the various types, benefits of wholesale purchasing, and crucial selection considerations, manufacturers can optimize their grinding operations. As industries continue to evolve, the demand for high-quality grinding wheels will remain integral to ensuring precision and excellence in manufacturing.