The Famous Bend Tube Polishing Machine A Key to Precision and Aesthetic Excellence

In the world of metal fabrication and finishing, the bend tube polishing machine has emerged as an indispensable tool for achieving both precision and aesthetic excellence. Known for its ability to process a variety of tube shapes, particularly those with bends and curves, this machine has become a staple in industries ranging from automotive to architectural design.

The primary function of a bend tube polishing machine is to enhance the surface quality of tubes that require a high degree of finish. This machine uses advanced polishing techniques to remove imperfections, align surface finishes with industry standards, and ensure that the final product not only performs well but also looks visually appealing. The importance of this process cannot be overstated, as the aesthetic quality of polished metal components can significantly influence the overall perception of a product.

One of the key features that set famous bend tube polishing machines apart from generic alternatives is their versatility. These machines are capable of handling various materials, including stainless steel, aluminum, and other alloys. This adaptability makes them suitable for numerous applications, from manufacturing sleek automotive exhaust systems to creating visually striking architectural railings. Additionally, many modern machines are equipped with programmable settings, allowing operators to customize polishing speeds and techniques based on the specific requirements of different jobs.

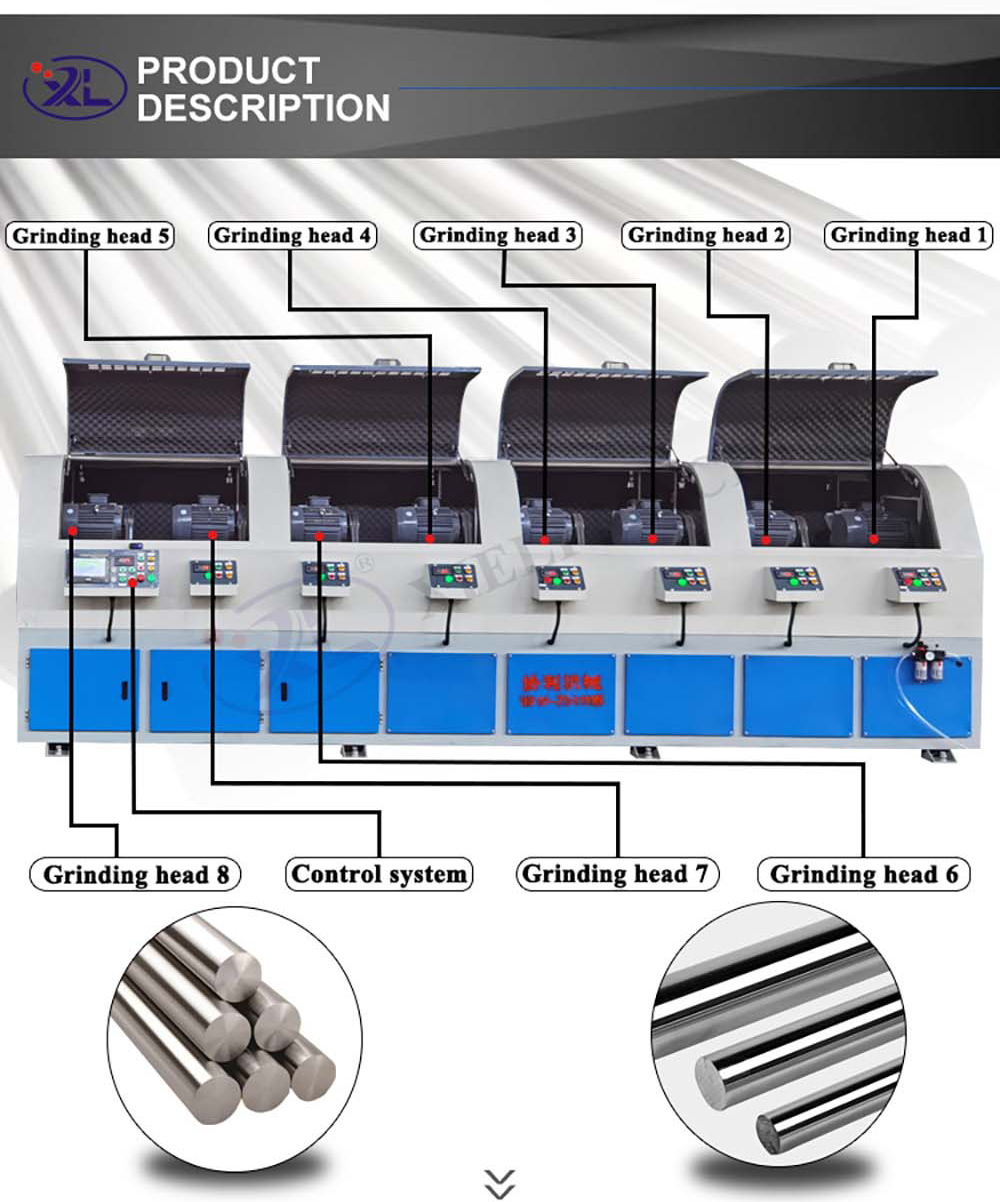

famous bend tube polishing machine

Efficiency is another cornerstone of the famous bend tube polishing machine. Many models utilize automated systems that reduce manual labor, ensure consistency in polishing quality, and boost overall productivity. Employees can rely on these machines to deliver precise results without the risk of human error, thereby allowing the workforce to focus on other critical aspects of production. This automation not only streamlines operations but also minimizes waste—a crucial factor in today’s environmentally-conscious manufacturing landscape.

Innovations in technology have also enhanced the performance of bend tube polishing machines. Contemporary models often incorporate features such as advanced dust collection systems, which not only keep the work area clean but also promote a safer working environment. Moreover, with the integration of user-friendly interfaces, operators can easily set parameters, monitor the polishing process, and quickly make necessary adjustments.

The role of a bend tube polishing machine extends beyond mere aesthetics. For industries that prioritize performance and safety, such as the aerospace and automotive sectors, polished tubes are essential for ensuring structural integrity and preventing corrosion. A well-polished surface can reduce the likelihood of wear and tear, ultimately extending the lifespan of components.

In conclusion, the famous bend tube polishing machine represents a blend of innovation, efficiency, and quality that is vital for modern manufacturing processes. By not only enhancing the appearance of products but also contributing to their functionality and longevity, these machines have solidified their place as critical assets across a wide range of industries. As technology continues to evolve, one can only anticipate further advancements in the capabilities of these remarkable polishing machines, shaping the future of metal fabrication.