-

Products Detail

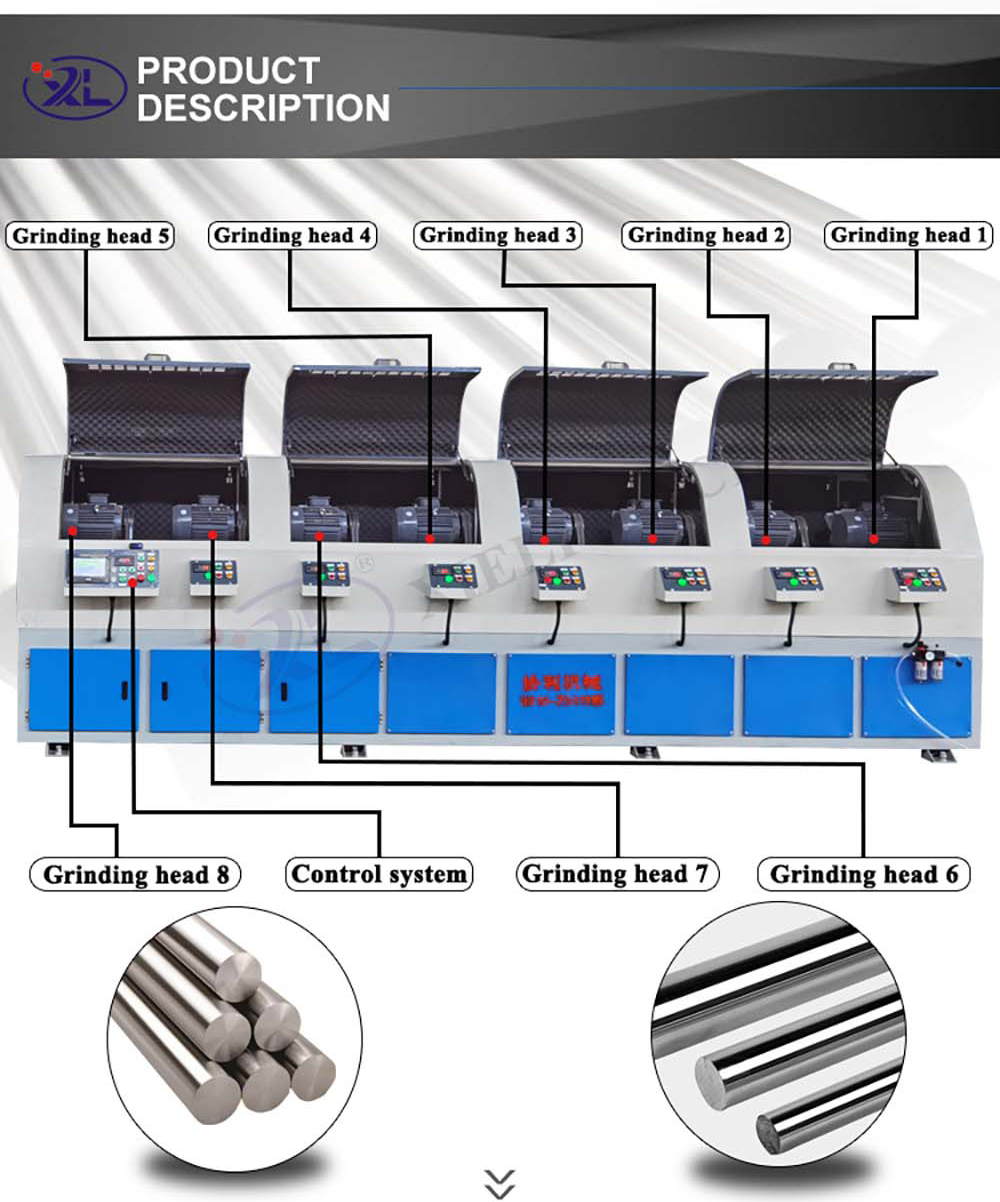

WX-DLZ Series Multi-station Vertical Polishing Machine

Main purpose and scope of application:

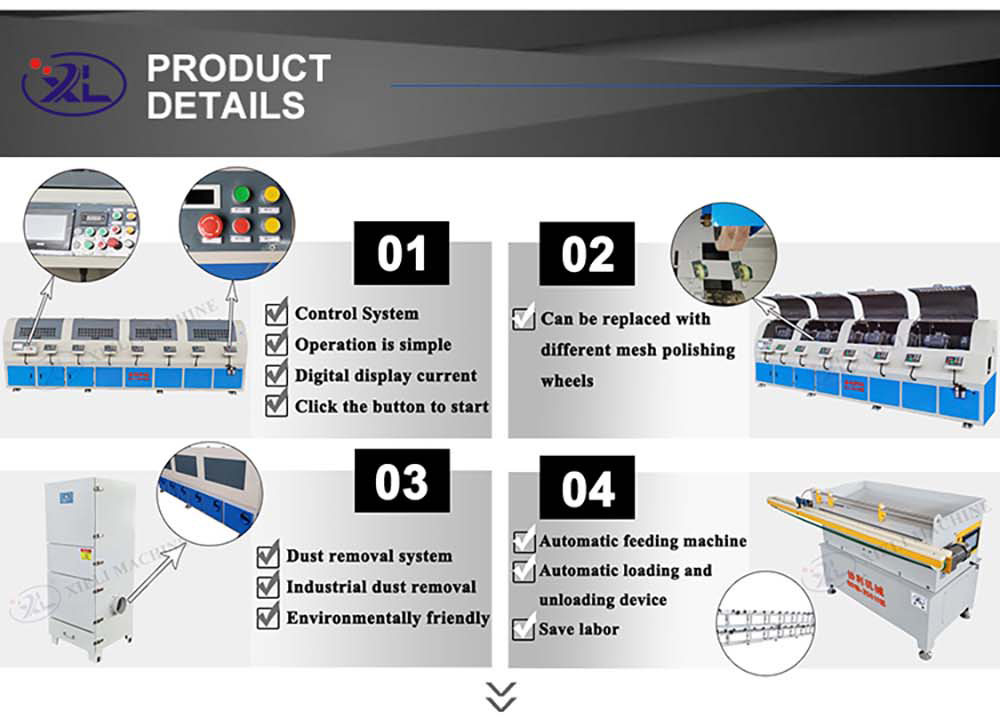

Round tube polisher is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. Round tube polisher is the best choice for polishing the round pipe, round rod and slender shaft. Round tube polisher can be equipped with a variety of polishing wheels, such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA etc. the guide wheel is stepless speed control, simple and convenient operation, and the steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dedusting fan or a wet dedusting system, which can be matched with an automatic loading and unloading mechanism according to the length of the processed parts.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DLZ-2

WX-DLZ-4

WX-DLZ-6

WX-DLZ-8

WX-DLZ-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

8.6

18

26.5

35.5

44

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel specification

110*70 (mm)

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

10-150

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Processing length(mm)

300-9000

Wet water cycle dust removal

optional

Dry fan dust removal

optional

Grinding head

feeding mode

Digital display electric adjustable

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weightabout(kg)

800

1600

2400

3200

4000

Equipment dimension

1.4*1.2*1.4

2.6*1.2*1.4

3.8*1.2*1.4

5.0*1.2*1.4

6.2*1.2*1.4

Stroj za poliranje okroglih cevi iz nerjavečega jekla je oprema za poliranje okroglih cevi. Polirana površina cevi je gladka in svetla, kar ustreza določenim industrijskim standardom. V nadaljevanju bo podrobno predstavljena uporaba stroja za poliranje okroglih cevi iz nerjavečega jekla.

- 1.Preparation for the operation of stainless steel round pipe polishing

- 2.Check whether the device is powered on and properly grounded.

- 3.Prepare the required abrasive and polishing paste to ensure that the abrasive and polishing paste matches the material to be processed.

- 4.Check and maintain the equipment in advance to ensure that the equipment is intact and all mechanical structures and lubricating oil are normal.

- 5.Wear safety glasses, gloves and other personal protective equipment to ensure the safe operation of personnel.

stainless steel round tube polishing machine operation steps

- 1.Put the round tube to be processed into the fixture and clamp it tightly, paying attention to the round tube clamping must be firm to avoid tube sliding.

- 2.Power on and press the start button to start the device.

- 3.Evenly apply the abrasive and polishing paste to the polishing head to ensure adequate coverage of the abrasive and polishing paste, which can effectively improve the polishing quality and efficiency.

- 4.Place the polishing head on the round tube and gently press the polishing head to start polishing. When polishing, the polishing head fluctuates down, and the swing amplitude should be gradually reduced from top to bottom until the polishing is stopped.

- 5.When polishing, each polishing time should be consistent, generally a few minutes, depending on the processing material and surface state. If it is the first processing or the surface of the rough material can be appropriate to extend the polishing time or increase the use of abrasive and polishing paste.

- 6.After polishing, observe the surface of the pipe, and if there is special need, the details can be locally polished to improve the appearance quality.

- 7.After the operation is complete, turn off the power supply, cut off the power supply, and clean the equipment, including the abrasive and polishing paste on the polishing head. If no one is operating, do not lock the door, and keep the ventilation smooth.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Afričan

- Albanec

- Amharščina

- arabščina

- Armenski

- Azerbajdžanščina

- baskovščina

- Beloruščina

- Bengalščina

- Bosanski

- Bolgarščina

- Katalonski

- Cebuansko

- Kitajska

- Kitajska (Tajvan)

- Korzikanec

- hrvaščina

- Češka

- Danščina

- Nizozemščina

- Angleščina

- Esperanto

- Estonščina

- Finski

- Francoščina

- Frizijščina

- galicijščina

- Gruzijska

- Nemščina

- Grščina

- gudžaratščina

- haitska kreolščina

- Havščina

- havajski

- Hebrejščina

- Ne

- Miao

- madžarščina

- Islandščina

- igbo

- Indonezijščina

- irski

- Italijanščina

- Japonščina

- Javanski

- Kannada

- kazahstanščina

- Kmerščina

- Ruandski

- Korejščina

- Kurdščina

- Kirgizijščina

- Delo

- Latinsko

- Latvijščina

- Litovščina

- Luksemburščina

- Makedonščina

- Madagaskarski

- Malajščina

- Malajalamščina

- Malteščina

- Maori

- Maratščina

- mongolščina

- Mjanmar

- Nepalščina

- norveščina

- norveščina

- Okcitanski

- Paštunščina

- perzijščina

- poljščina

- Portugalščina

- pandžabščina

- Romunščina

- Ruščina

- Samoanski

- Škotska gelščina

- Srbščina

- Angleščina

- Shona

- Sindhi

- Sinhala

- Slovaščina

- slovenščina

- Somalščina

- Španščina

- Sundanščina

- svahili

- švedščina

- Tagalog

- Tadžik

- Tamilščina

- Tatar

- Telugu

- Tajska

- turščina

- Turkmenščina

- Ukrajinščina

- Urdujščina

- Ujgur

- Uzbek

- Vietnamščina

- Valižanščina

- Pomoč

- Jidiš

- Zulu