-

Products Detail

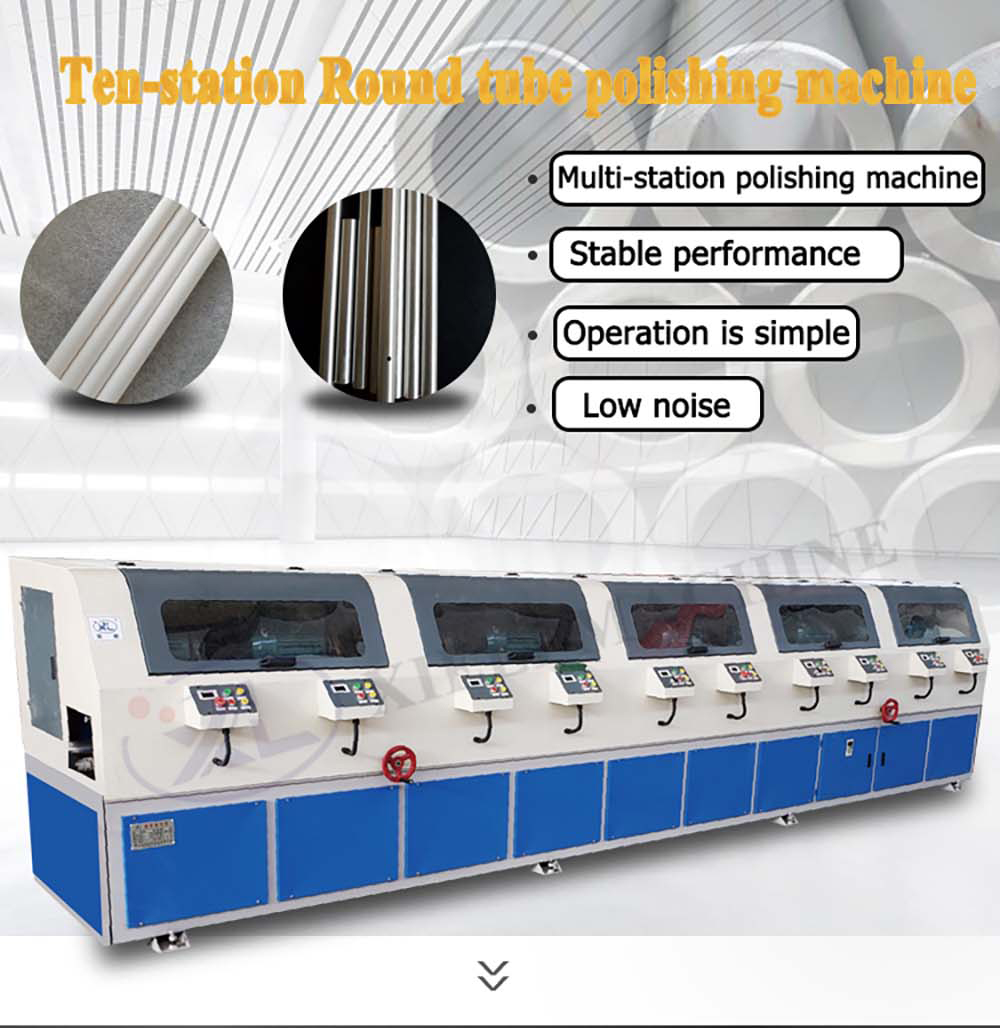

WX-DLZ Series Multi-station Vertical Polishing Machine

Main purpose and scope of application:

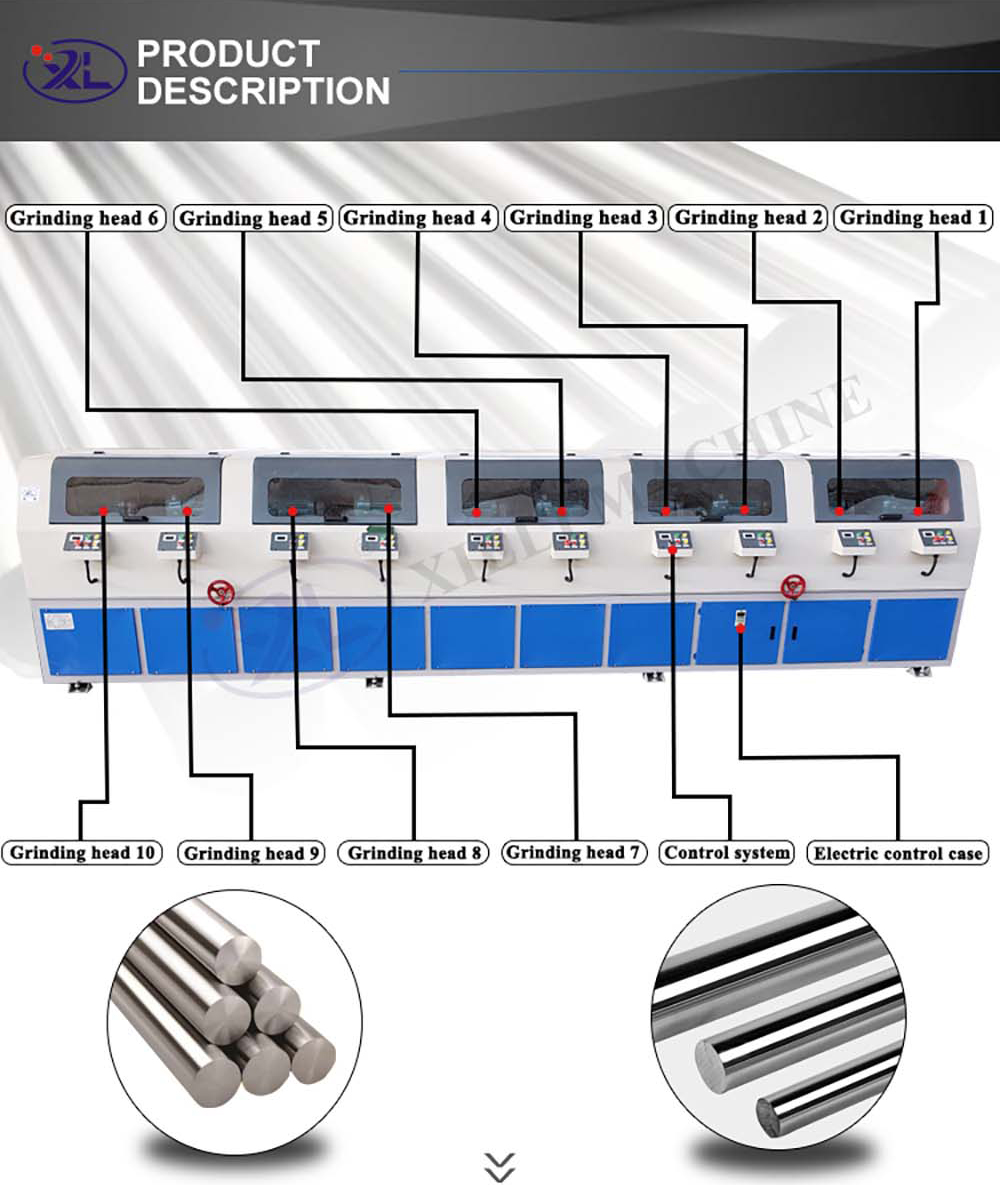

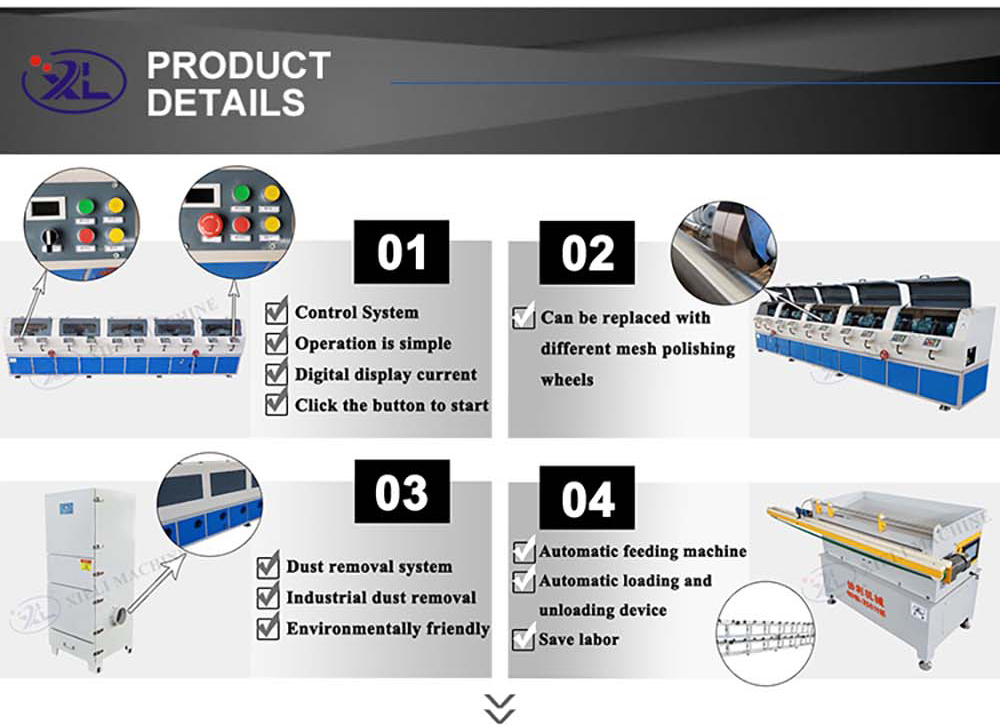

Round tube polisher is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. Round tube polisher is the best choice for polishing the round pipe, round rod and slender shaft. Round tube polisher can be equipped with a variety of polishing wheels, such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA etc. the guide wheel is stepless speed control, simple and convenient operation, and the steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dedusting fan or a wet dedusting system, which can be matched with an automatic loading and unloading mechanism according to the length of the processed parts.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DLZ-2

WX-DLZ-4

WX-DLZ-6

WX-DLZ-8

WX-DLZ-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

8.6

18

26.5

35.5

44

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel specification

110*70 (mm)

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

10-150

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Processing length(mm)

300-9000

Wet water cycle dust removal

optional

Dry fan dust removal

optional

Grinding head

feeding mode

Digital display electric adjustable

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weightabout(kg)

800

1600

2400

3200

4000

Equipment dimension

1.4*1.2*1.4

2.6*1.2*1.4

3.8*1.2*1.4

5.0*1.2*1.4

6.2*1.2*1.4

the classification of stainless steel pipe polishing machine

Stainless steel pipe polishing machine according to its structure is mainly classified into inner and outer circle polishing machine and only outer circle polishing machine two kinds, its main convenience is that it can respectively for the inner circle and the outer circle of the pipe for different degrees of polishing treatment.

Second, the characteristics of stainless steel pipe polishing machine

1, heavy grinding technology: the polishing head adopts heavy grinding technology to ensure that the pressure between the pipe axis and the polishing head is within a certain range, so as to ensure the consistency of the entire pipe.

2, full automatic control: full automatic control, simple and convenient operation, high efficiency, can greatly improve production efficiency.

3, high-precision motion system: the use of high-precision stepper motor and transmission device, can ensure the accuracy and stability of the polishing head.

4, automatic cleaning system: equipment inside and outside the cleaning system are automatic control, simple operation, automatic shrinkage, reduce manual intervention.

5, automatic adjustment support belt system: automatic adjustment support belt system has high automaticity and reliability, can achieve the correct connection between the polishing head and the pipe, and ensure the processing efficiency.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- 아프리카 사람

- 알바니아

- 암하라어

- 아라비아 말

- 아르메니아 사람

- 아제르바이잔

- 바스크 사람

- 벨라루스어

- 벵골 사람

- 보스니아어

- 불가리아 사람

- 카탈로니아 사람

- 세부아노어

- 중국

- 중국(대만)

- 코르시카어

- 크로아티아어

- 체코 사람

- 덴마크 말

- 네덜란드 사람

- 영어

- 에스페란토 말

- 에스토니아 사람

- 핀란드어

- 프랑스 국민

- 프리지아어

- 갈리시아어

- 그루지야 사람

- 독일 사람

- 그리스 사람

- 구자라트어

- 아이티 크리올어

- 하우사어

- 하와이안

- 헤브라이 사람

- 아니요

- 먀오족

- 헝가리 인

- 아이슬란드어

- 이그보

- 인도네시아 인

- 아일랜드

- 이탈리아 사람

- 일본어

- 자바어

- 칸나다어

- 카자흐어

- 크메르어

- 르완다

- 한국인

- 쿠르드어

- 키르기스어

- 노동

- 라틴어

- 라트비아 사람

- 리투아니아 사람

- 룩셈부르크어

- 마케도니아 어

- 마다가스카르 사람

- 말레이 사람

- 말라얄람어

- 몰티즈

- 마오리족

- 마라티어

- 몽고 어

- 미얀마

- 네팔어

- 노르웨이 인

- 노르웨이 인

- 오크어

- 파슈토어

- 페르시아 인

- 광택

- 포르투갈 인

- 펀잡어

- 루마니아 사람

- 러시아인

- 사모아인

- 스코틀랜드 게일어

- 세르비아 사람

- 영어

- 쇼나어

- 신디어

- 싱할라어

- 슬로바키아 사람

- 슬로베니아

- 소말리아

- 스페인 사람

- 순다어

- 스와힐리어

- 스웨덴어

- 타갈로그어

- 타지크어

- 타밀 사람

- 타타르어

- 텔루구어

- 태국어

- 터키어

- 투르크멘 말

- 우크라이나 말

- 우르두어

- 위구르족

- 우즈베크어

- 베트남 사람

- 웨일스 말

- 돕다

- 이디시어

- 줄루 족