-

Products Detail

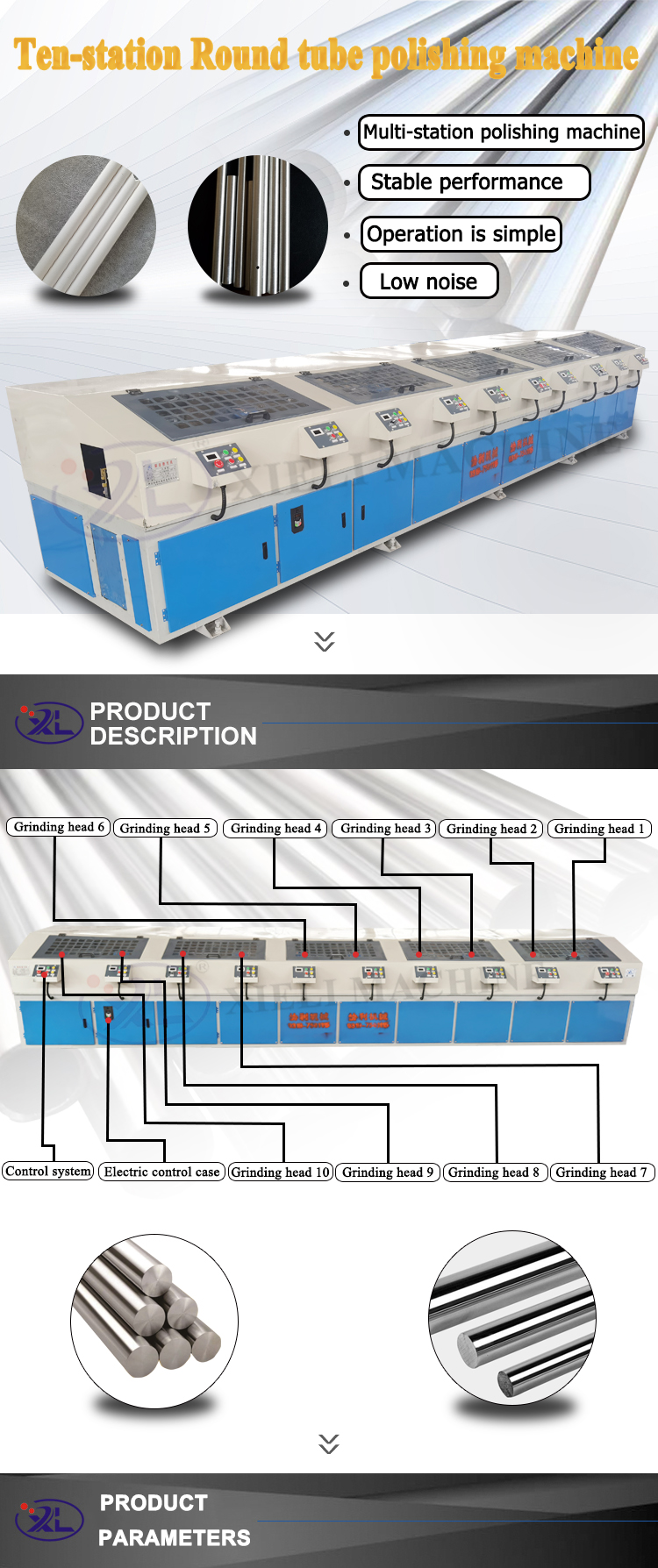

WX-DWZ Series Multi-station Round Tube Polishing Machine

Main purpose and scope of application:

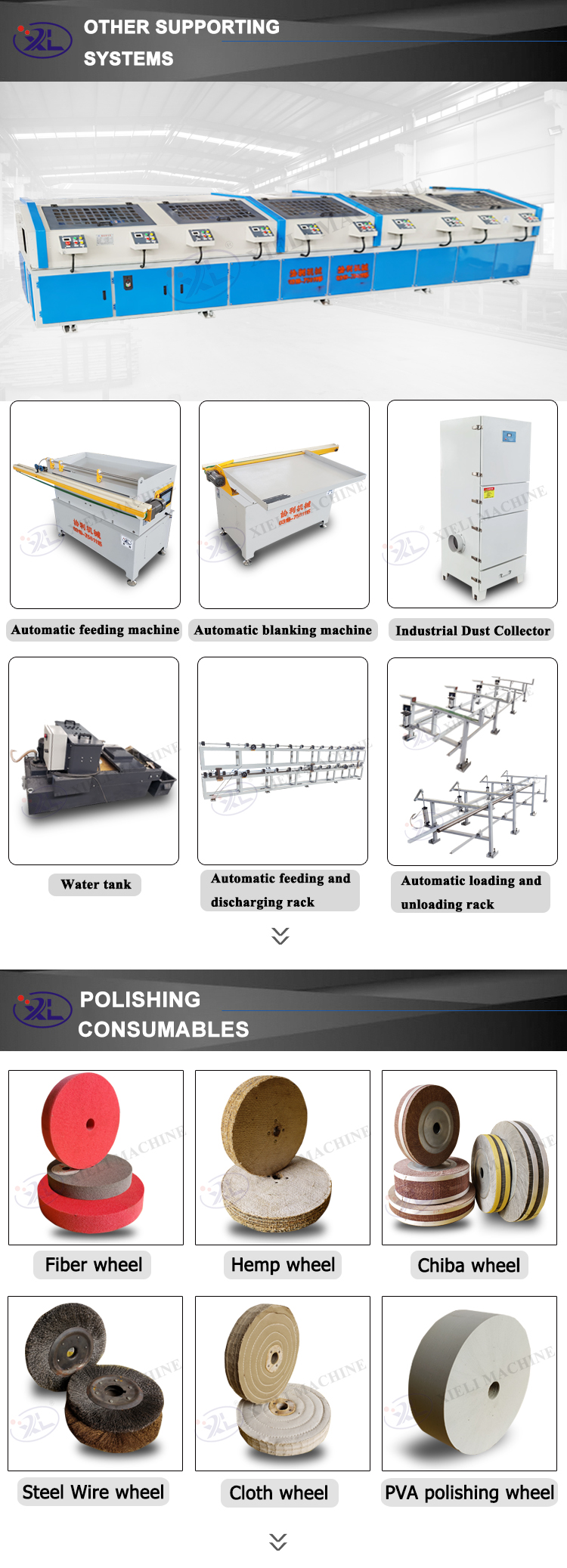

Round pipe polisher is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. Round pipe polisher is the best choice for polishing the round pipe, round rod and slender shaft. The round tube polisher can be equipped with a variety of polishing wheels, such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA etc. the guide wheel is stepless speed control, simple and convenient operation, and the steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dedusting fan or a wet dedusting system, which can be matched with an automatic loading and unloading mechanism according to the length of the processed parts.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DWZ-2

WX-DWZ-4

WX-DWZ-6

WX-DWZ-8

WX-DWZ-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

8.6

18

26.5

35.5

44

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel

specification(mm)

100*200

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

4-100

Processing efficiency(m/min)

0-20

Surface roughness (um)

Ra 0.02

Processing length(mm)

100-6000

Wet water cycle dust removal

optional

Dry fan dust removal

optional

Feeding mode of grinding head

Digital display electric adjustable

Machine tool Total weight about(kg)

800

1600

2400

3200

4000

Equipment Overall dimension(m)

1.4*1.2*1.0

2.6*1.2*1.0

3.8*1.2*1.0

5.0*1.2*1.0

6.2*1.2*1.0

Stainless steel pipe factory polishing round pipe how to polish the pipe bright? First of all, it is best to use the automatic round tube polishing machine, you can use sand belt, or impeller for oxide treatment, according to the required effect, you can use different types of sand belt or polishing wheel, this step is called sand, generally after sand treatment on the surface there is brightness, If the sand can pass the sand belt of No. 1000, it can be directly electroplated.

2, after sand use hemp wheel cloth wheel polishing, hemp wheel can use purple wax, cloth wheel can use wax or white wax, waxing according to different effects, the spindle speed should be around 2220 RPM best, if you do not understand can consult Kunshan Yongzhicheng mechanical technology Department

The name of the outer circle polishing machine.

Kružni stroj za poliranje poznat je i kao stroj za poliranje bez centra, kružni stroj za poliranje bez centra, stroj za poliranje kružnih cijevi, stroj za poliranje vitke osovine.

Classification of cylindrical polishers

According to the shape of the workpiece can be divided into plane polishing machine, ball polishing machine, square tube polishing machine, strip polishing machine. According to its polishing process, it can be divided into a single group of cylindrical polishing machine and multiple groups of vertical cylindrical polishing machine and multiple groups of horizontal polishing machine.

The use of cylindrical polishing machine

Cylindrical polishing machine is mainly used in hardware manufacturing, vehicle parts, steel and wood furniture, instrument machinery, standard parts and other industries before and after electroplating rust and polishing, is the best choice for round pipe, round rod, slender shaft polishing. The workpiece processed by the circular tube polishing machine has high brightness and does not affect the original size of the workpiece, which is especially suitable for the high-gloss polishing of the workpiece processed by the centerless grinder.Centerless circular polishing machine is a common polishing machine, mainly used to polish round tube material, also known as circular tube polishing machine, when using this polishing machine, sometimes there will be loud noise, what is the reason?

1, do not use the polishing machine for a period of time, the surface of the polishing machine has a little dust, and the bearing rust of the polishing machine is used again, resulting in the motor can not rotate, resulting in noise.

- 2,The motor is damaged.

- 3,When the polishing machine is polishing, the grinding head is violently vibrated by the unbalanced force, and the dynamic instability phenomenon causes noise.

- 4,The gear meshing surface is worn or there is too much backlash during gear assembly, resulting in meshing noise during transmission.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- afrički

- Albanski

- Amharski

- arapski

- Armenski

- Azerbajdžanski

- baskijski

- Bjeloruski

- bengalski

- bosanski

- bugarski

- katalonski

- Cebuano

- Kina

- Kina (Tajvan)

- Korzikanac

- hrvatski

- češki

- danski

- Nizozemski

- engleski

- esperanto

- estonski

- Finski

- francuski

- frizijski

- galicijski

- gruzijski

- njemački

- grčki

- gudžaratski

- haićanski kreolski

- hausa

- havajski

- Hebrejski

- Ne

- Miao

- Mađarski

- Islandski

- igbo

- indonezijski

- irski

- talijanski

- japanski

- javanski

- Kannadski

- kazaški

- Kmerski

- Ruandanac

- korejski

- kurdski

- Kirgizi

- Rad

- latinski

- Latvijski

- litvanski

- Luksemburški

- makedonski

- Madagaskarski

- malajski

- Malajalamski

- malteški

- Maori

- Marathi

- mongolski

- Mjanmar

- Nepalski

- Norveški

- Norveški

- Okcitanski

- Paštunski

- perzijski

- Polirati

- portugalski

- Pandžapski

- Rumunjski

- ruski

- Samoanski

- Škotski galski

- Srpski

- engleski

- Shona

- Sindhi

- Sinhalski

- slovački

- slovenski

- Somalijski

- španjolski

- Sundanski

- Svahili

- švedski

- Tagalog

- Tadžik

- Tamil

- tatarski

- Telugu

- Tajlandski

- turski

- Turkmenski

- ukrajinski

- urdu

- Ujgur

- uzbečki

- vijetnamski

- velški

- Pomoć

- jidiš

- zulu