-

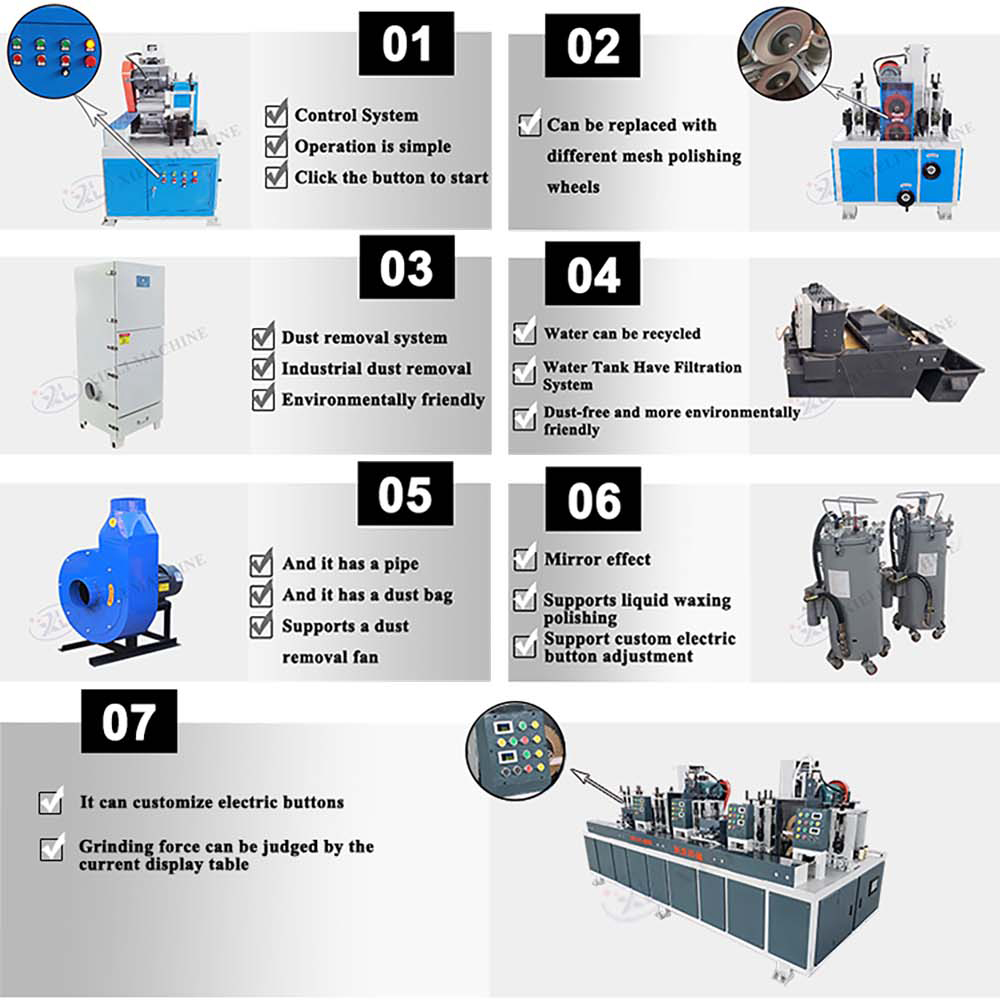

Products Detail

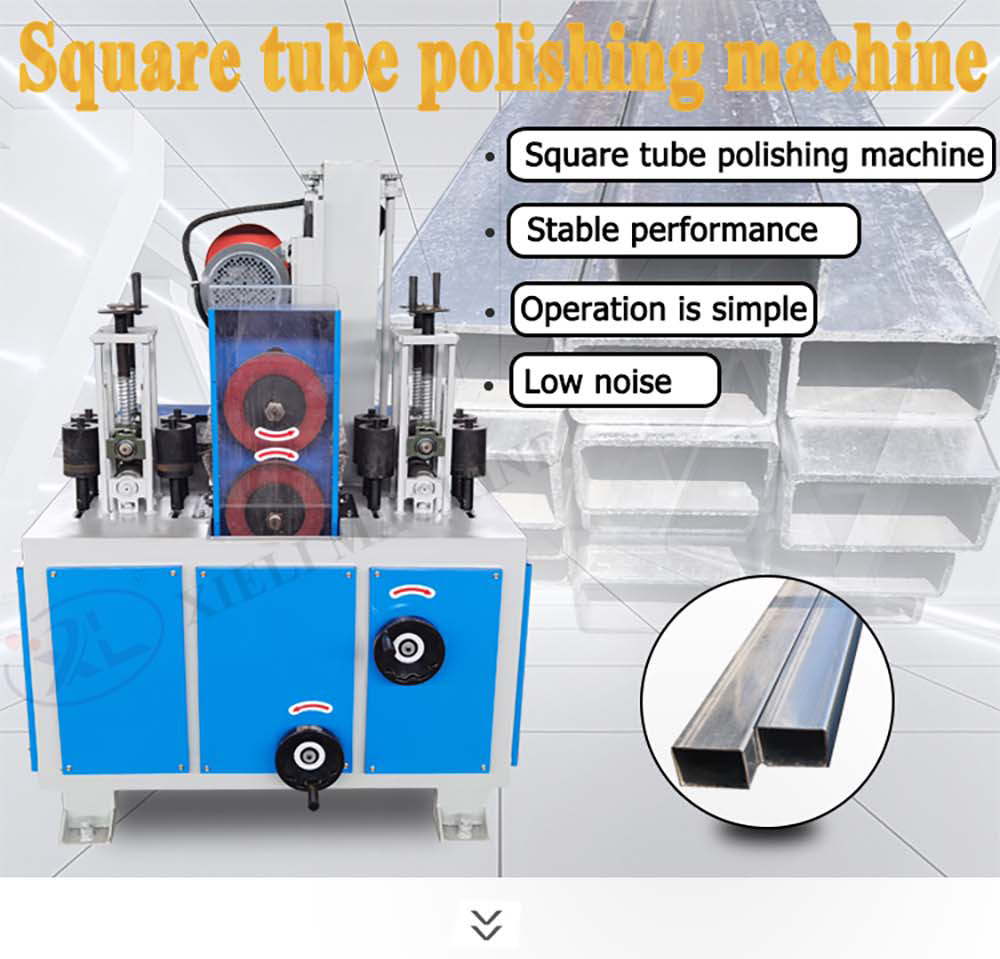

FG series square tube polishing machine

Main purpose and scope of application:

Is suitable for rectangular cross-section profiles such as square tube, square steel, strip steel, hexagonal square steel/square pipe and other metal or non-metallic surface derusting, wire drawing and 8 k mirror polishing, polishing grinding uses the dry form, can choose a variety of grinding materials and tool, (emery cloth Chiba wheel, hemp wheel, nylon wheel, cloth wheel, PVA, and wool wheel), each time can complete the multi-channel different degree of grinding, through reform the polishing wheel shape can also be for polishing profiled section.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

FG-2

FG-4

FG-8

FG-16

FG-24

polished square tube specifications(mm)

120

10*10X120*120

160

10*10X160*160

200

50*50X200*200

300

50*50X300*300

Polishing grinding heads number, (pcs.)

2

4

8

16

24

Machined workpiece length(m)

0.8-12

Steel pipe feed speed(m/min)

0-20(It can be customized according to the user's requirements)

External diameter of matching polishing wheel(mm)

250-300

Grinding head speed(r/min)

2800

Grinding head spindle diameter(mm)

120

32

160

32

200

50

300

50

Grinding head motor power(KW)

120

4

160

5.5

200

7.5

300

11

Grinding head feed mode

Manual / digital display electric (optional)

Dedusting method

Dry fan bag

the characteristics of the square tube rust polishing machine

- 1.High work efficiency

The electronic control system of the square tube polishing machine is accurate and sensitive, which can not only automatically position and process the tube accurately, but also carry out high-speed processing. The processing efficiency of the square tube polishing machine is superior to the traditional manual and mechanical polishing technology, which can save time and labor costs.

2, polishing quality is good

The cutting parameters of the square tube polishing machine are calculated and controlled by the electronic control system, which can carry out high-precision polishing of the other tube, and the polished edge is smooth and neat, and the gloss is high, which meets the polishing needs of high quality and high standards.

- 3.Diversified to meet demand

The square tube polishing machine can complete a variety of polishing processes, and can meet the needs of square tubes with different shapes, different sizes and different materials, which is convenient for customers and makes the application range of the equipment wider.

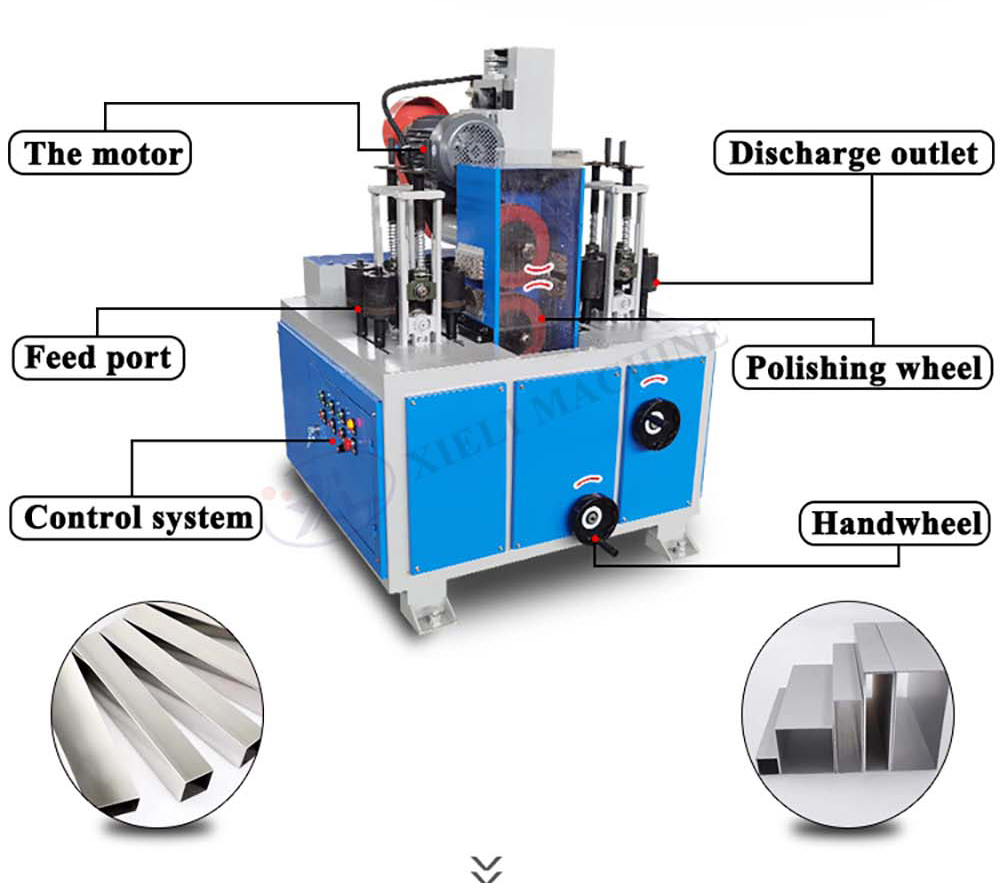

Second, the working principle of the square tube polishing machine

The core of the square tube polishing machine is a rotating belt grinding wheel, grinding wheel group, dressing wheel group, transmission system and spectral control system and other main modules. After starting the machine, the square tube is transported to the working area of the machine, and after precise positioning and clamping, the processing begins.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- umAfrika

- Isi-Albania

- Isi-Amharic

- Isi-Arabhu

- Isi-Armenian

- Isi-Azerbaijani

- Isi-Basque

- IsiBelarusian

- Isi-Bengali

- Isi-Bosnia

- IsiBulgaria

- IsiCatalan

- Cebuano

- China

- I-China (Taiwan)

- IsiCorsican

- IsiCroatia

- IsiCzech

- Isi-Danish

- IsiDashi

- IsiNgisi

- Isi-Esperanto

- Isi-Estonian

- IsiFinnish

- IsiFulentshi

- IsiFrisian

- IsiGalicia

- IsiGeorgia

- IsiJalimane

- isiGreki

- IsiGujarati

- IsiCreole saseHaiti

- IsiHausa

- isi-hawaiian

- IsiHebheru

- Cha

- Miao

- IsiHungary

- Isi-Icelandic

- igbo

- Isi-Indonesian

- i-irish

- IsiNtaliyane

- IsiJapane

- Isi-Javanese

- Isi-Kannada

- kazakh

- I-Khmer

- OwaseRwanda

- IsiKorea

- IsiKurdish

- IsiKyrgyz

- Umsebenzi

- IsiLatini

- Isi-Latvian

- IsiLithuanian

- Isi-Luxembourgish

- IsiMacedonian

- Isi-Malagasy

- Isi-Malay

- Isi-Malayalam

- IsiMaltese

- IsiMaori

- IsiMarathi

- IsiMongolia

- eMyanmar

- IsiNepali

- IsiNorwegian

- IsiNorwegian

- Isi-Occitan

- Isi-Pashto

- isiPheresiya

- IsiPolish

- IsiPutukezi

- IsiPunjabi

- IsiRomania

- IsiRashiya

- IsiSamoa

- IsiScottish Gaelic

- IsiSerbia

- IsiNgisi

- IsiShona

- Sindhi

- IsiSinhala

- IsiSlovak

- IsiSlovenian

- eSomalia

- ISpanishi

- IsiSundanese

- IsiSwahili

- IsiSwidi

- IsiTagalog

- Isi-Tajik

- IsiTamil

- IsiTatar

- Isi-Telugu

- IsiThai

- IsiTurkey

- IsiTurkmen

- Isi-Ukraine

- Isi-Urdu

- Isi-Uighur

- Isi-Uzbek

- IsiVietnamese

- Isi-Welsh

- Usizo

- Isi-Yiddish

- Zulu