-

Chi tiết sản phẩm

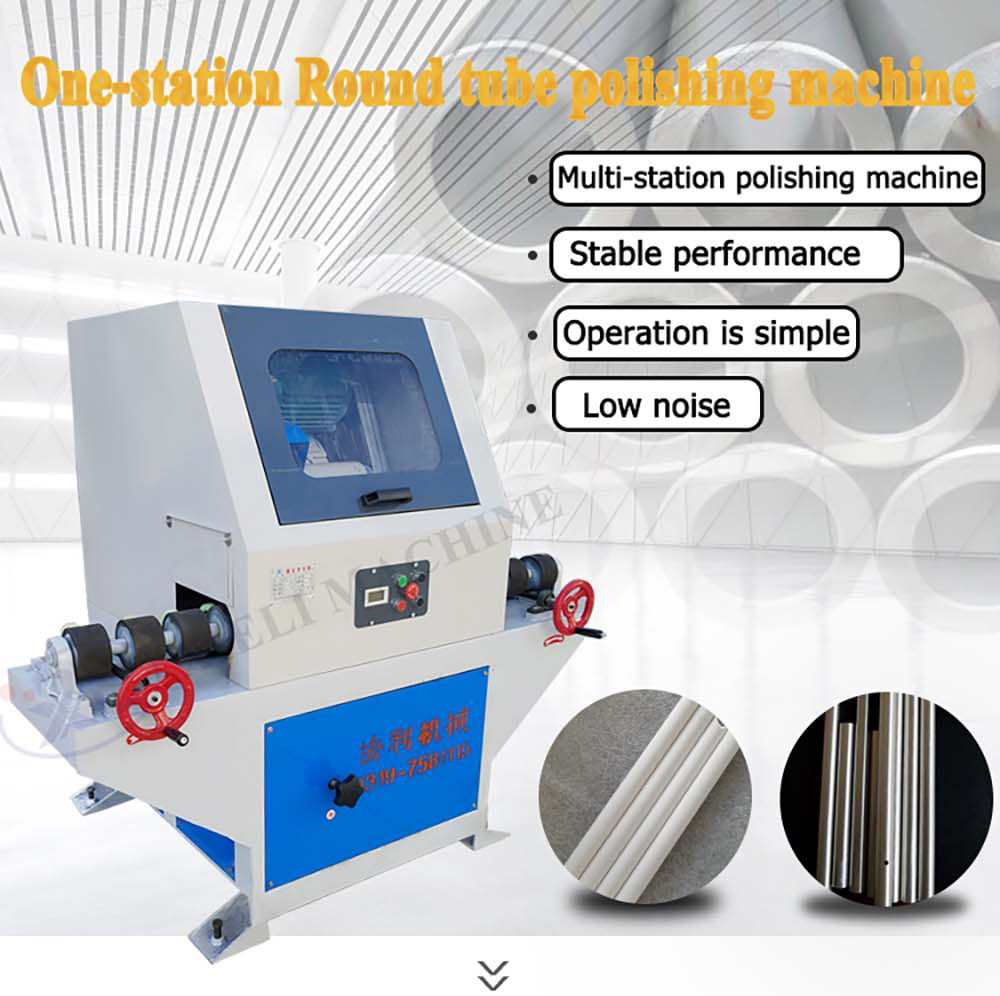

WX-DLZ Series Multi-station Vertical Polishing Machine

Mục đích chính và phạm vi áp dụng:

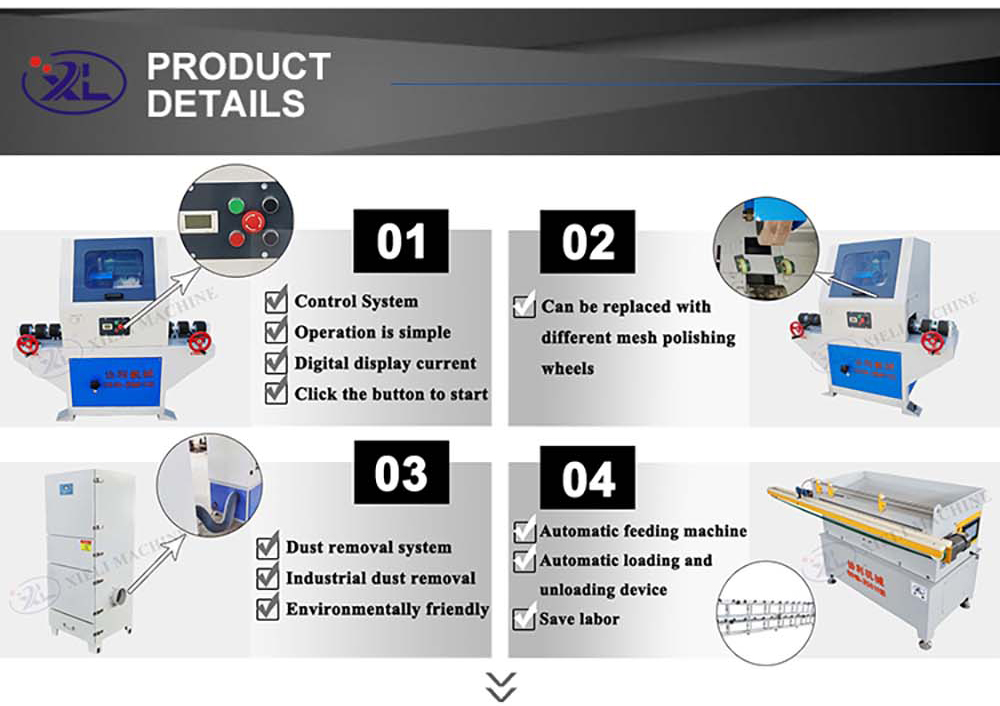

Round tube polisher is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. Round tube polisher is the best choice for polishing the round pipe, round rod and slender shaft. Round tube polisher can be equipped with a variety of polishing wheels, such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA etc. the guide wheel is stepless speed control, simple and convenient operation, and the steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dedusting fan or a wet dedusting system, which can be matched with an automatic loading and unloading mechanism according to the length of the processed parts.

Các thông số kỹ thuật chính:

(Thiết bị đánh bóng chuyên dụng có thể tùy chỉnh theo yêu cầu của người sử dụng)

Dự án

Người mẫu

WX-DLZ-2

WX-DLZ-4

WX-DLZ-6

WX-DLZ-8

WX-DLZ-10

Điện áp đầu vào (v)

380V (Ba pha bốn dây)

Input power(kw)

8.6

18

26.5

35.5

44

Bánh đánh bóng

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel specification

110*70 (mm)

Bánh đánh bóng

tốc độ (vòng/phút)

3000

Guide wheel speed(r/min)

Điều chỉnh tốc độ vô cấp

Đường kính gia công (mm)

10-150

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ngày 0.02

Processing length(mm)

300-9000

Loại bỏ bụi bằng chu trình nước ướt

không bắt buộc

Loại bỏ bụi quạt khô

không bắt buộc

Grinding head

feeding mode

Màn hình kỹ thuật số có thể điều chỉnh điện

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weightabout(kg)

800

1600

2400

3200

4000

Equipment dimension

1.4*1.2*1.4

2.6*1.2*1.4

3.8*1.2*1.4

5.0*1.2*1.4

6.2*1.2*1.4

round tube polishing machine and cylindrical polishing machine introduction:

The round tube polishing machine is composed of polishing and feeding two major mechanisms using the principle of centerless grinding. By adjusting the feed amount of the grinding head, the workpiece can be grinding or fine grinding and polishing, and the workpiece of different specifications can be adjusted by adjusting the spacing of the guide wheel.The feeding mechanism of the machine adopts a stepless variable speed device, which can make the workpiece achieve the ideal grinding effect by changing the feed speed of the workpiece. And according to the different materials and polishing requirements of the workpiece can be flexibly selected emery cloth page wheel, hemp wheel, cloth wheel, nylon wheel and other polishing tools for polishing the workpiece, the workpiece tray is made of wear-resistant materials, you do not need to adjust the workpiece specifications change adjustment, the machine adopts a one-way moving bidirectional structure, which greatly simplifies the adjustment of the tray. The complete production line is composed of three parts: polishing machine feeding device and discharging device, and has a variety of models such as standard type, automatic type, environmental protection type and economic type for users to choose from. The number of host grinding head can be specified when ordering according to the original condition of the workpiece surface and the finish requirement of the finished product surface.

-

Bạn cần dịch vụ và báo giá của chúng tôi?

Yêu cầu báo giá

Nếu bạn quan tâm đến sản phẩm của chúng tôi, bạn có thể để lại thông tin tại đây và chúng tôi sẽ sớm liên hệ với bạn.

- Châu Phi

- Tiếng Albania

- Tiếng Amharic

- Tiếng Ả Rập

- Tiếng Armenia

- Tiếng Azerbaijan

- Tiếng Basque

- người Belarus

- Tiếng Bengal

- người Bosnia

- Tiếng Bulgaria

- Tiếng Catalan

- Tiếng Cebuano

- Trung Quốc

- Trung Quốc (Đài Loan)

- người Corsica

- Tiếng Croatia

- Tiếng Séc

- Tiếng Đan Mạch

- Tiếng Hà Lan

- Tiếng Anh

- Tiếng Esperanto

- Tiếng Estonia

- Phần Lan

- Tiếng Pháp

- Tiếng Frisia

- Tiếng Galicia

- người Gruzia

- Tiếng Đức

- Tiếng Hy Lạp

- Tiếng Gujarat

- Tiếng Creole Haiti

- Tiếng Hausa

- người Hawaii

- Tiếng Do Thái

- KHÔNG

- Miêu

- Tiếng Hungary

- Tiếng Iceland

- người Igbo

- Tiếng Indonesia

- người Ai-len

- Tiếng Ý

- Tiếng Nhật

- Tiếng Java

- Tiếng Kannada

- tiếng kazakh

- Tiếng Khmer

- người Rwanda

- Hàn Quốc

- người Kurd

- Tiếng Kyrgyzstan

- Lao

- Tiếng La-tinh

- Tiếng Latvia

- Tiếng Litva

- Tiếng Luxembourg

- Tiếng Macedonia

- Tiếng Malagasy

- Tiếng Mã Lai

- Tiếng Mã Lai

- Tiếng Malta

- Người Maori

- Tiếng Marathi

- Mông Cổ

- Miến Điện

- Tiếng Nepal

- Tiếng Na Uy

- Tiếng Na Uy

- Tiếng Occitan

- Tiếng Pashto

- Tiếng Ba Tư

- Đánh bóng

- Tiếng Bồ Đào Nha

- Tiếng Punjab

- Tiếng Rumani

- Tiếng Nga

- Người Samoa

- Tiếng Gaelic Scotland

- Tiếng Serbia

- Tiếng Anh

- Shona

- Tiếng Sindhi

- Tiếng Sinhala

- Tiếng Slovak

- Tiếng Slovenia

- Tiếng Somali

- Tiếng Tây Ban Nha

- Tiếng Sunda

- Tiếng Swahili

- Tiếng Thụy Điển

- Tiếng Tagalog

- Tiếng Tajik

- Tiếng Tamil

- Người Tatar

- Tiếng Telugu

- Thái Lan

- Thổ Nhĩ Kỳ

- Người Turkmen

- Tiếng Ukraina

- Tiếng Urdu

- Người Duy Ngô Nhĩ

- Tiếng Uzbek

- Tiếng Việt

- Tiếng Wales

- Giúp đỡ

- Tiếng Yiddish

- Tiếng Zulu