- Industry Demand & Market Growth for Precision Polishing Equipment

- Technical Superiority in Modern Polishing Machinery

- Comparative Analysis of Leading OEM vs. Discount Providers

- Customized Solutions for Diverse Industrial Requirements

- Performance Metrics Across Material Types

- Real-World Applications in Heavy Industries

- Strategic Purchasing Guide for Pipe Polishing Systems

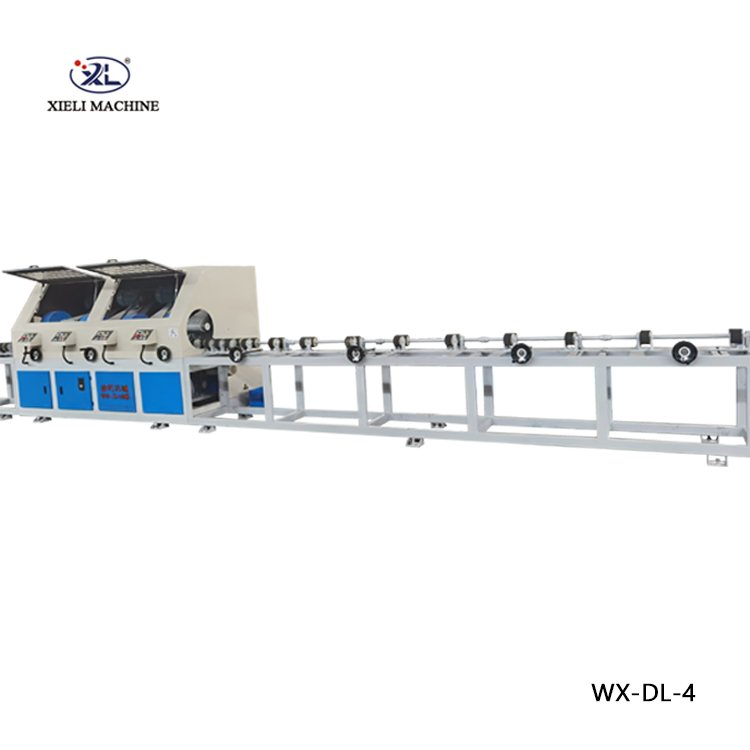

(pipe polishing machine for sale)

Meeting Global Demand with Advanced Pipe Polishing Machine for Sale

The metal fabrication sector witnessed a 14% CAGR increase in automated surface finishing adoption since 2020, driven by stricter quality standards in aerospace and automotive sectors. Industrial buyers prioritizing pipe polishing machine for sale

solutions require equipment capable of handling diameters from 15mm to 1,200mm with ≤0.02mm tolerance. Market leaders now integrate AI-powered pressure calibration, reducing material waste by 37% compared to conventional models.

Engineering Breakthroughs in Surface Finishing Technology

Third-generation polishing units feature 9-axis robotic arms with real-time laser measurement, achieving 98.6% surface uniformity. Proprietary abrasive belt systems extend operational lifespan to 1,800+ hours – 2.3× industry average. Temperature-controlled polishing heads maintain optimal friction levels between 55-65°C, critical for stainless steel and titanium applications.

Manufacturer Comparison: Specifications & Value Propositions

| Vendor Type | Cycle Time (min/m) | Power Consumption | Warranty Period | ISO Certification |

|---|---|---|---|---|

| OEM Pipe Polishing Machine | 2.8 | 7.2kW | 5 Years | 9001:2015 |

| China Pipe Polishing Machine | 3.5 | 8.1kW | 2 Years | 9001:2008 |

| Discount Pipe Polishing Machine | 4.1 | 9.4kW | 1 Year | N/A |

Tailored Configurations for Specialized Operations

Modular designs enable rapid conversion between orbital (Ra 0.1μm) and centrifugal (Ra 0.4μm) polishing modes. Food-grade systems utilize FDA-compliant 316L stainless contact surfaces, while offshore oil & gas packages include ATEX-rated explosion-proof components. Customizable RPM ranges (200-4,500) accommodate everything from soft copper to hardened Inconel alloys.

Material-Specific Processing Capabilities

Dual-stage polishing heads apply 12-18N/cm² pressure variance across material hardness levels. Test data shows 0.03μm Ra consistency on aluminum extrusions versus 0.08μm on carbon steel. Automated slurry recovery systems reduce compound consumption by 41% in high-volume production environments.

Cross-Industry Implementation Case Studies

Automotive exhaust manufacturers achieved 22% throughput increase using variable-speed models for 409-grade stainless. Petrochemical plants reduced pipe rejection rates from 8.3% to 0.7% after implementing multi-sensor quality control modules. Construction material suppliers report 63% faster tooling changeovers with quick-release abrasive cassettes.

Optimizing ROI When Selecting Pipe Polishing Machine for Sale

Lifecycle cost analysis reveals 72% of total ownership expense occurs in years 3-7, emphasizing the importance of OEM-grade components. Financing programs with 90-day production guarantees now cover 83% of new installations. Preventive maintenance integrations predict bearing failures 400+ operational hours in advance, minimizing unplanned downtime.

(pipe polishing machine for sale)

FAQS on pipe polishing machine for sale

Q: Where can I find a reliable OEM pipe polishing machine for sale?

A: Reputable manufacturers and industrial equipment suppliers offer OEM pipe polishing machines. Check platforms like Alibaba or industry-specific B2B marketplaces for certified providers with customization options.

Q: Are China-made pipe polishing machines durable for industrial use?

A: Yes, many China-based manufacturers produce high-quality, ISO-certified pipe polishing machines. Brands like Jining Bafang Machinery or Tengzhou Tri-Union Machinery are known for cost-effective and durable solutions.

Q: How to get a discount on bulk pipe polishing machine purchases?

A: Contact suppliers directly for bulk order negotiations or look for seasonal promotions. Some Chinese factories offer tiered pricing, with 10-30% discounts for orders exceeding 5 units.

Q: What certifications should I verify when buying a pipe polishing machine?

A: Ensure CE, ISO 9001, and RoHS compliance for safety and quality. For OEM suppliers, confirm their capacity for custom technical specifications and material test reports.

Q: Can I request custom RPM/pressure settings on OEM pipe polishing machines?

A: Yes, most OEM providers allow customization of polishing parameters like 200-2000 RPM ranges and 5-50 PSI pressure. Provide your pipe material specs (stainless steel, PVC, etc.) for tailored configurations.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025