-

Products Detail

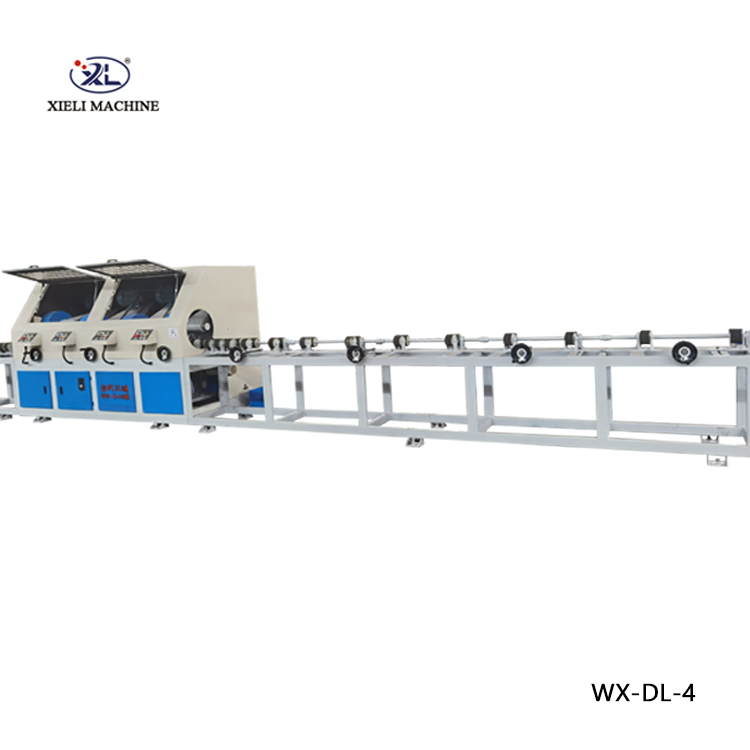

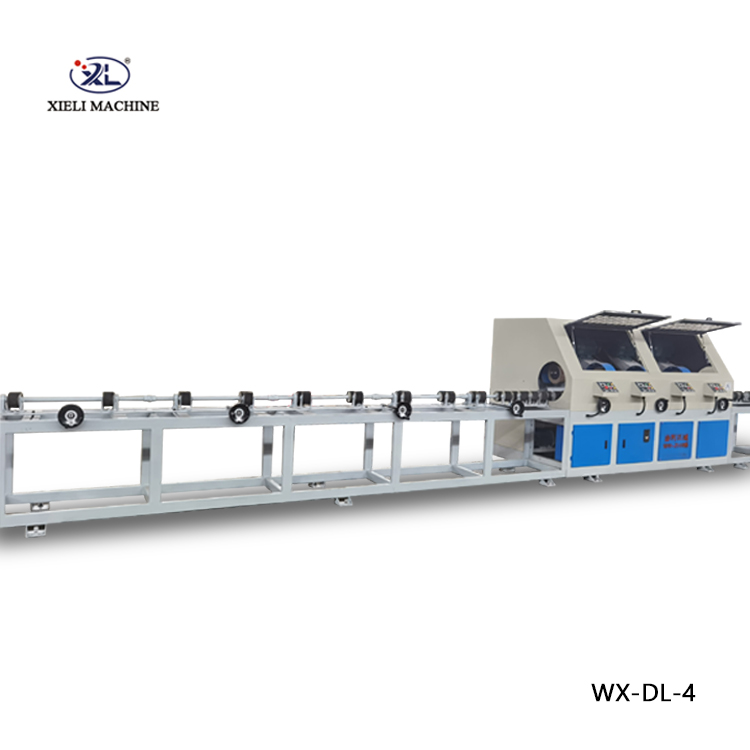

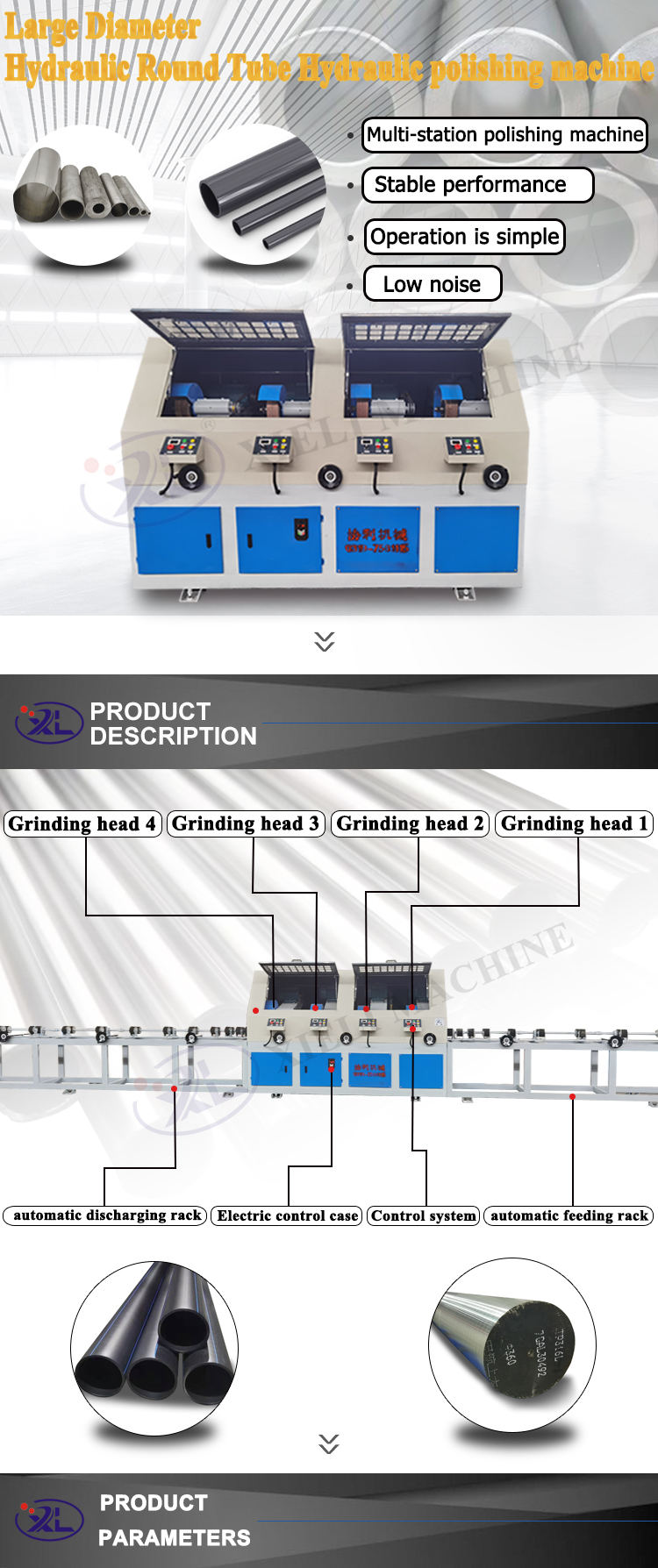

WX-DL series large diameter hydraulic tube polishing machine

Main purpose and scope of application:

Round pipe polishing machine is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. A variety of brown and white corundum grinding wheels and polishing wheels such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA, etc. can be installed in the round tube polishing machine. The guide wheel has stepless speed control, which is simple and convenient to operate. The steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dust removal fan or a wet dust removal system, which can be matched with an automatic feeding and unloading mechanism according to the length of the processed parts. This device It can be equipped with grinding wheel to grind pin and remove oxide skin (peeling off) on the surface of round steel and pipe with serious defects.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DL-2

WX-DL-4

WX-DL-6

WX-DL-8

WX-DL-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

13.2

22.2

30.7

38.7

46.7

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel

specification(mm)

110

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

20-360

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Processing length(mm)

Determined by bracket length (0.3-12)

Dry fan dust removal

optional

Wet water cycle dust removal

optional

Grinding head

feeding mode

Digital display electromagnetic hydraulic control

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weight about(kg)

2000

3000

4000

5000

6000

Equipment dimension(m)

1.3*1.2*1.5

2.6*1.2*1.5

3.9*1.2*1.5

5.2*1.2*1.5

6.5*1.2*1.5

There are many factors affecting the polishing effect during the polishing process of the device using the automatic cylindrical tube polishing machine, which needs to be carefully paid attention to. Now, circular polishing machine company to say, circular tube cylindrical centerless polishing machine function circular polishing machine use precautions:

1, when the cylindrical polishing machine is in use, the device grinding surface and the polishing disc should be absolutely parallel and evenly gently pressed on the polishing disc, and attention should be paid to prevent the sample from flying out and new grinding marks due to too much pressure. At the same time, the device should also be rotated and moved back and forth along the radius of the turntable to avoid local wear of the polished fabric too fast.

2, in the use of cylindrical polishing machine polishing process to continue to add fine powder suspension, so that the polishing fabric to maintain a certain humidity. Too much humidity will weaken the abrasive effect of polishing, and make the hard phase in the sample appear convex and the non-metallic inclusions in steel and the graphite phase in cast iron produce "trailing" phenomenon. When the humidity is too small, the sample will be heated due to friction heat, the lubrication effect will be reduced, the grinding surface will lose luster, and even black spots will appear, and the light alloy will hurt the surface.

The guide wheel of the large-diameter hydraulic round tube polishing machine rotates by stepless speed regulation, which can better meet the grinding or polishing of different diameters and different lengths of the workpiece.

Because the guide wheel of the machine rotates by stepless speed regulation, the polishing workpiece is more efficient, the finish is better, and the abrasive consumables are extensive and durable. The large diameter hydraulic round pipe polishing machine has the advantages of simple and convenient operation, stable product performance and low noise, and is well received by the majority of users.

Optional cooling system and dust collection system are used to meet different industries. This machine reserved fan port users can also install their own dust removal fan. Scope of application: Used in industries: hardware, electroplating, furniture, standard parts, auto and motorcycle parts and hydraulic transmission and other manufacturing industries.

It is used for grinding or polishing the outer surface of various round tubes, round rods, shafts and rods. It is suitable for polishing the workpiece after processing by centerless cylindrical grinding machine.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- アフリカ

- アルバニア語

- アムハラ語

- アラビア語

- アルメニア語

- アゼルバイジャン語

- バスク語

- ベラルーシ語

- ベンガル語

- ボスニア語

- ブルガリア語

- カタルーニャ語

- セブアノ語

- 中国

- 中国(台湾)

- コルシカ

- クロアチア語

- チェコ語

- デンマーク語

- オランダ語

- 英語

- エスペラント

- エストニア語

- フィンランド語

- フランス語

- フリジア語

- ガリシア語

- ジョージア語

- ドイツ語

- ギリシャ語

- グジャラート語

- ハイチ語

- ハウサ語

- ハワイアン

- ヘブライ語

- いいえ

- ミャオ族

- ハンガリー語

- アイスランド語

- イボ語

- インドネシア語

- アイルランド人

- イタリア語

- 日本語

- ジャワ語

- カンナダ語

- カザフ語

- クメール語

- ルワンダ

- 韓国語

- クルド

- キルギス

- 労働

- ラテン

- ラトビア語

- リトアニア語

- ルクセンブルク語

- マケドニア語

- マダガスカル語

- マレー語

- マラヤーラム語

- マルタ語

- マオリ語

- マラーティー語

- モンゴル語

- ミャンマー

- ネパール語

- ノルウェー語

- ノルウェー語

- オック語

- パシュトー語

- ペルシャ語

- 研磨

- ポルトガル語

- パンジャブ語

- ルーマニア語

- ロシア

- サモア語

- スコットランド・ゲール語

- セルビア語

- 英語

- ショナ語

- シンディー語

- シンハラ語

- スロバキア語

- スロベニア語

- ソマリア

- スペイン語

- スンダ語

- スワヒリ語

- スウェーデン語

- タガログ語

- タジク語

- タミル語

- タタール語

- テルグ語

- タイ語

- トルコ語

- トルクメン語

- ウクライナ語

- ウルドゥー語

- ウイグル族

- ウズベク語

- ベトナム語

- ウェールズ語

- ヘルプ

- イディッシュ語

- ズールー語