-

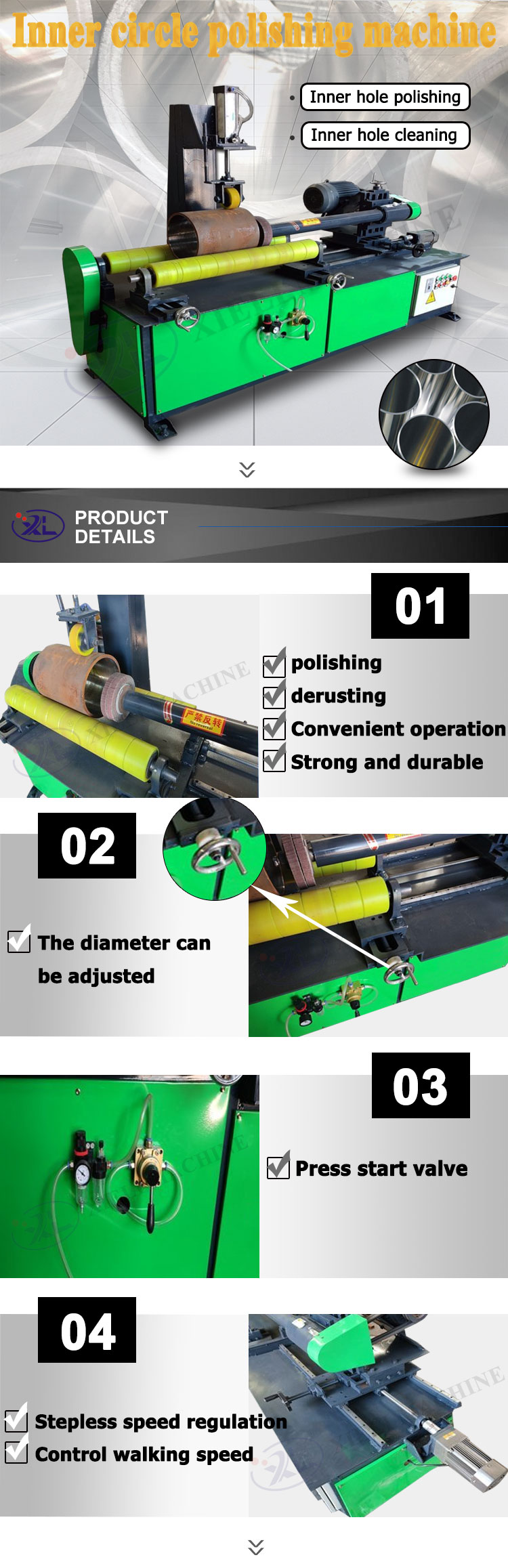

Products Detail

Product Name

inner circle polishing machine

model

XL-NY

Dimensions

2500*700*1300mm(Size depends on the model)

weight

700kg

Motor Power

4kw

Diameter of polishing wheel

50-250mm

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Afirka

- Albaniya

- Amharic

- Larabci

- Armenian

- Azerbaijan

- Basque

- Belarushiyanci

- Bengali

- Bosniya

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Yaren mutanen Holland

- Turanci

- Esperanto

- Estoniya

- Finnish

- Faransanci

- Farisa

- Galiciyan

- Jojin

- Jamusanci

- Girkanci

- Gujarati

- Haitian Creole

- hausa

- hawayi

- Ibrananci

- A'a

- Miya

- Harshen Hungary

- Icelandic

- igbo

- Indonesiya

- Irish

- Italiyanci

- Jafananci

- Yawanci

- Kannada

- kazakh

- Khmer

- Ruwanda

- Yaren Koriya

- Kurdish

- Kyrgyzstan

- Aiki

- Latin

- Latvia

- Lithuaniyanci

- Luxembourgish

- Makidoniya

- Malagasy

- Malay

- Malayalam

- Maltase

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Yaren mutanen Norway

- Yaren mutanen Norway

- Occitan

- Pashto

- Farisa

- Yaren mutanen Poland

- Fotigal

- Punjabi

- Romanian

- Rashanci

- Samoan

- Scottish Gaelic

- Serbian

- Turanci

- Shona

- Sindhi

- Sinhala

- Slovak

- Harshen Sloveniya

- Somaliya

- Mutanen Espanya

- Sundanci

- Harshen Swahili

- Yaren mutanen Sweden

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Baturke

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Taimako

- Yadish

- Zulu