-

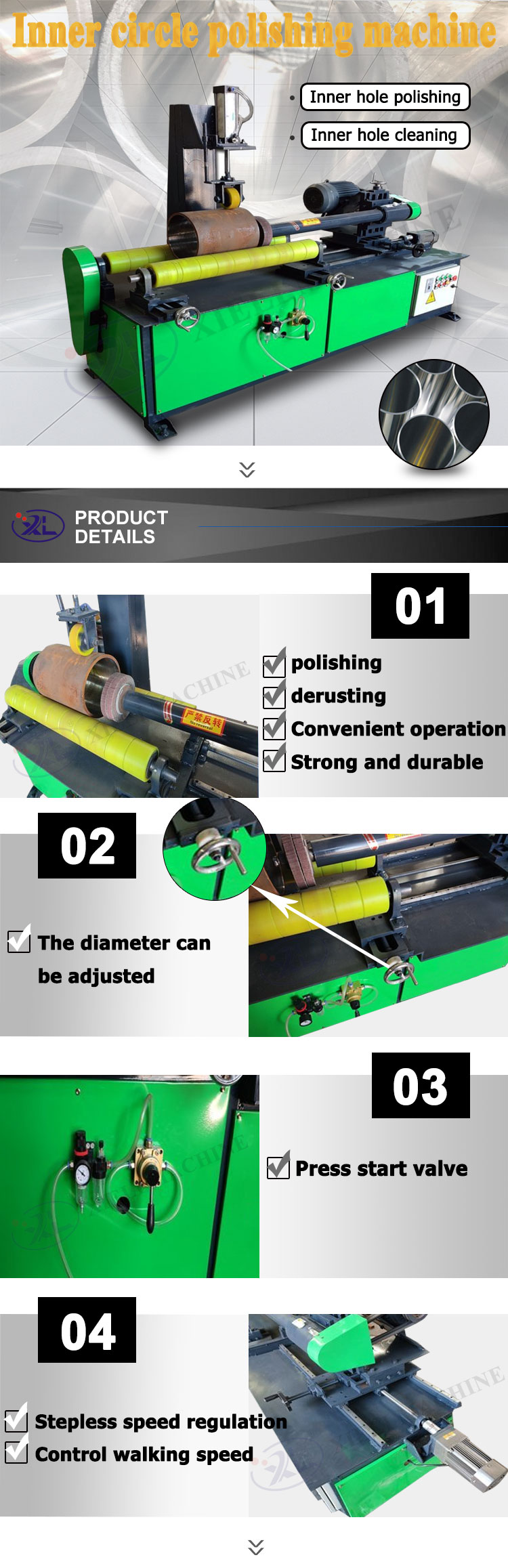

Products Detail

Product Name

inner circle polishing machine

model

XL-NY

Dimensions

2500*700*1300mm(Size depends on the model)

weight

700kg

Motor Power

4kw

Diameter of polishing wheel

50-250mm

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Affricanaidd

- Albaneg

- Amhareg

- Arabeg

- Armeneg

- Azerbaijani

- Basgeg

- Belarwseg

- Bengali

- Bosneg

- Bwlgareg

- Catalaneg

- Cebuano

- Tsieina

- Tsieina (Taiwan)

- Corseg

- Croateg

- Tsieceg

- Daneg

- Iseldireg

- Saesneg

- Esperanto

- Estoneg

- Ffinneg

- Ffrangeg

- Ffriseg

- Galiseg

- Georgegaidd

- Almaeneg

- Groeg

- Gwjarataidd

- Creol Haitian

- Hausa

- hawaiian

- Hebraeg

- Na

- Miao

- Hwngareg

- Islandeg

- igbo

- Indoneseg

- Gwyddelig

- Eidaleg

- Japaneg

- Javaneg

- Kannada

- kazakh

- Khmer

- Rwandaidd

- Coreeg

- Cwrdeg

- Kyrgyz

- Llafur

- Lladin

- Latfieg

- Lithwaneg

- Lwcsembwrgeg

- Macedoneg

- Malagaseg

- Malayeg

- Malayalam

- Malteg

- Maori

- Marathi

- Mongolaidd

- Myanmar

- Nepali

- Norwyeg

- Norwyeg

- Ocsitaneg

- Pashto

- Perseg

- Pwyleg

- Portiwgaleg

- Punjabi

- Rwmaneg

- Rwsieg

- Samoaidd

- Gaeleg yr Alban

- Serbaidd

- Saesneg

- Shona

- Sindhi

- Sinhala

- Slofaceg

- Slofeneg

- Somaliaidd

- Sbaeneg

- Sundaneg

- Swahili

- Swedeg

- Tagalog

- Tajic

- Tamil

- Tatar

- Telugu

- Thai

- Twrceg

- Tyrcmeneg

- Wcreineg

- Wrdw

- Uighur

- Wsbeceg

- Fietnameg

- Cymraeg

- Cymorth

- Iddew-Almaeneg

- Swlw