In high-volume manufacturing, precision, efficiency, and consistency are key. Centerless grinding machines have emerged as one of the most reliable solutions for mass production industries due to their ability to perform high-precision grinding while maintaining speed and minimal human intervention. These machines are designed to handle high volumes of parts with excellent repeatability and consistency.

The Efficiency of Centerless Cylindrical Grinding

One of the main reasons centerless cylindrical grinding is favored in mass production is its ability to grind parts continuously without the need for a traditional fixture or holding device. Unlike conventional cylindrical grinding, where parts must be clamped or mounted in a chuck, centerless cylindrical grinding relies on the alignment of the workpiece with the grinding wheel and regulating wheel. This setup allows parts to be fed into the machine and ground without interruption, making it an ideal choice for industries where high throughput is essential.

With centerless cylindrical grinding, the process can be automated, reducing downtime and increasing production speed. This is especially important in industries such as automotive, aerospace, and medical device manufacturing, where parts must be ground to precise tolerances quickly and consistently.

How Centerless Cylindrical Grinding Machines Improve Production Rates

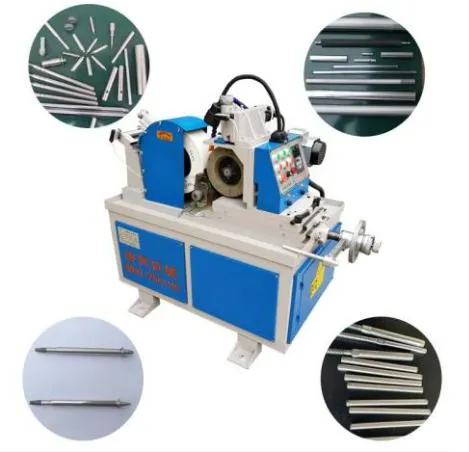

Centerless cylindrical grinding machines are specifically designed to support high-volume production by combining precision and speed. These machines allow for continuous grinding of cylindrical parts, such as shafts, pins, and bearings, at much faster rates than conventional grinding machines. With the right setup, a centerless cylindrical grinding machine can process hundreds or even thousands of parts in a single day with minimal operator intervention.

What sets centerless grinding equipment apart is its ability to maintain consistent part quality over long production runs. The machine’s design ensures that each part is held in the same position throughout the grinding process, minimizing variation in the final product. This consistency is essential for manufacturers looking to produce large quantities of parts with minimal quality control issues.

The Role of CNC Centerless Grinders in Mass Production

For even greater precision and flexibility, many high-volume manufacturers turn to CNC centerless grinders. These machines are equipped with computer numerical control (CNC) systems that allow for automated adjustments to the grinding process. This means that operators can easily set the machine to grind parts to specific tolerances, and the CNC system will automatically adjust settings like speed, feed rate, and wheel position.

The inclusion of CNC technology in centerless grinders enhances their capability for mass production, as these machines can quickly switch between different part types without the need for manual recalibration. This is a game-changer for industries that need to produce a variety of parts with different specifications on the same machine, further improving efficiency and reducing setup times.

Why CNC Centreless Grinding Machines Are Preferred in High-Precision Industries

In industries where precision is non-negotiable, CNC centreless grinding machines are often the preferred choice. These machines are capable of achieving tight tolerances, down to the microns, making them indispensable in sectors like aerospace, automotive, and medical device manufacturing. With the ability to adjust grinding parameters automatically, CNC centreless grinding machines ensure that each part is consistently ground to the exact specifications required.

Moreover, these machines offer a high level of versatility, as they can handle a wide range of materials, from stainless steel to titanium, and can be used to grind both simple and complex parts. This versatility makes CNC centreless grinding machines an ideal solution for manufacturers producing a wide variety of components in high volumes.

Streamlining Mass Production with Centerless Grinding Equipment

As industries continue to demand faster production times and higher-quality parts, centerless grinding equipment stands out as a solution that meets both needs. By eliminating the need for clamping, reducing setup times, and allowing for high-speed processing, centerless grinding machines enable manufacturers to maintain high production rates while ensuring parts are ground to precise specifications. Whether using centerless cylindrical grinding or a CNC centerless grinder, the end result is the same: high-quality parts produced efficiently and consistently.

These machines also reduce the amount of operator intervention required, which helps minimize errors and ensures that the process is as automated as possible. The ability to run 24/7 without frequent interruptions makes centerless grinding equipment a reliable choice for high-volume manufacturers aiming to boost their productivity.

Centerless grinding machines offer a variety of benefits that make them an ideal choice for high-volume production. From their ability to grind parts continuously without interruptions to the advanced capabilities of CNC centreless grinding machines, these machines provide manufacturers with the precision, efficiency, and consistency they need to stay competitive. By choosing the right machine for your needs, you can ensure that your high-volume production process runs smoothly and meets the highest standards of precision and quality.