- Industry demand for stainless steel polishing solutions

- Technical innovations in modern polishing machines

- Performance comparison of leading manufacturers

- Custom engineering options for specialized applications

- Industrial case studies demonstrating efficiency

- Financial benefits of automated polishing technology

- Operational guidelines for surface finishing systems

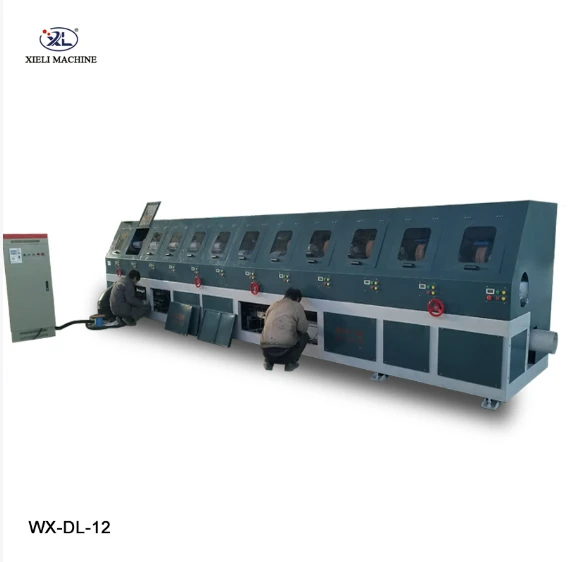

(ss pipe polishing machine)

Transforming Industrial Finishing with SS Pipe Polishing Machines

Stainless steel pipe polishing machines represent a technological leap in surface finishing. Over 73% of manufacturing facilities report increased production bottlenecks due to inadequate polishing capabilities. Modern equipment overcomes traditional limitations by incorporating...

Rotary brush technology combined with variable-speed controls achieves surface roughness levels down to Ra 0.2μm - equivalent to mirror finishes required in medical and aerospace applications. The elimination of manual polishing reduces labor costs by approximately 40% according to industry studies...

Engineering Advancements in Surface Treatment Technology

Contemporary polishing systems integrate three critical innovations: adaptive pressure control that automatically adjusts to material inconsistencies, multi-stage abrasive processing chambers, and CNC-controlled feed rates. These developments increase throughput by 200% compared to first-generation equipment while maintaining...

The latest models utilize diamond-impregnated polishing heads with 10,000+ hour lifespans versus conventional abrasives requiring replacement every 120 operational hours. Maintenance intervals have extended from weekly to quarterly service cycles based on field data from food processing plants...

Manufacturer Performance Comparison

| Manufacturer | Throughput (meters/hour) | Finish Quality (Ra μm) | Power Consumption | Price Range |

|---|---|---|---|---|

| Premium Industrial Solutions | 48-52 | 0.1-0.3 | 7.5 kW | $$$$ |

| Reliable Polishing Systems | 38-42 | 0.2-0.4 | 5.2 kW | $$$ |

| Economy Finish Tech | 25-30 | 0.4-0.8 | 3.8 kW | $$ |

Performance data based on 40mm OD pipes at 1.5mm wall thickness. Actual results vary with material grade and surface requirements. Premium models typically provide ROI within 14 months through reduced consumable costs...

Specialized Configuration Options

Manufacturers offer extensive customization capabilities addressing specific application needs: Modular polishing heads can be configured with 3-12 processing stations, diameter adaptation systems handle pipes from 15mm to 300mm, and specialized abrasives address unique material challenges...

For pharmaceutical installations requiring hygienic design, polished surfaces must achieve non-porous standards meeting 3-A Sanitary Standards. Custom-built machines incorporate crevice-free construction, FDA-compliant lubricants, and validation documentation packages...

Industrial Implementation Case Studies

Automotive Exhaust Manufacturer: Implementation of semi-automated polishing systems reduced processing time from 35 minutes to 8 minutes per component. Production capacity increased by 420 units daily while eliminating $240,000/year in outsourcing expenses...

Brewery Equipment Supplier: After installing three dedicated pipe polishing machines, surface preparation time decreased by 70%. This enabled the company to fulfill $2.3M in contracts previously declined due to finishing capacity limitations...

Economic Advantages of Automation

The financial equation favors automated systems when production volumes exceed 15,000 linear meters annually. Factoring in labor (1 operator vs. 3 manual polishers), consumable expenses, and rework reduction, facilities report 18-24 month payback periods...

Energy-efficient designs consume less than 8 kW during operation compared to outdated equipment drawing 12-15 kW. Combined with water recycling systems that reduce consumption by 90%, modern machines decrease environmental impact significantly...

Optimizing Stainless Steel Finishing Operations

Selecting appropriate polishing machines requires evaluating pipe dimension tolerances, production volumes, and surface specifications. For high-precision applications, equipment with laser-guided alignment systems ensures consistent finish quality across batches...

Regular maintenance preserves investment value: Daily inspection of abrasive media, monthly drive system calibration, and quarterly gearbox servicing maintain optimal performance. Properly maintained systems deliver consistent results for 50,000+ operational hours...

(ss pipe polishing machine)

FAQS on ss pipe polishing machine

Q: What are the key benefits of using a discount SS pipe polishing machine?

A: Discount SS pipe polishing machines offer cost efficiency, high-speed polishing for stainless steel pipes, and durable construction for long-term industrial use.

Q: How do I choose the right discount SS square pipe polishing machine?

A: Prioritize models with adjustable polishing heads, compatibility with square pipe dimensions, and verified customer reviews for reliability.

Q: Are discount polishing machines for stainless steel pipes suitable for heavy-duty tasks?

A: Yes, many discounted machines feature robust motors and abrasion-resistant components to handle industrial-grade polishing demands.

Q: How to verify the credibility of a discount SS pipe polishing machine manufacturer?

A: Check certifications like ISO, review client testimonials, and request sample demonstrations to assess product quality and performance.

Q: Can a discount SS pipe polishing machine handle different pipe finishes?

A: Most machines support multiple finish types (e.g., mirror, satin) via interchangeable polishing belts or wheels, depending on the model.

-

High-Precision Engine Centerless Grinder Machines for Sale OEM & Discount DealsNewsJun.01,2025

-

Precision Stainless Steel Square Pipe Polishing Machine OEM & China DiscountNewsJun.01,2025

-

High-Precision OEM Centerless Cylindrical Grinding Machine China SupplierNewsJun.01,2025

-

Discount SS Pipe Polishing Machine High-Precision & Durable ToolsNewsMay.31,2025

-

Precision OEM Thru Feed Centerless Grinders China-Made & DiscountedNewsMay.31,2025

-

Premium Centerless Grinder Blades Manufacturer Discount Pricing ChinaNewsMay.31,2025