- Overview of centerless grinding technology and market position

- Technical specifications and production advantages

- Leading manufacturers comparison

- Custom OEM solutions for specialized applications

- Cost-benefit analysis of Chinese manufacturing

- Industry-specific implementation case studies

- Final recommendations for equipment selection

(centerless cylindrical grinding machine)

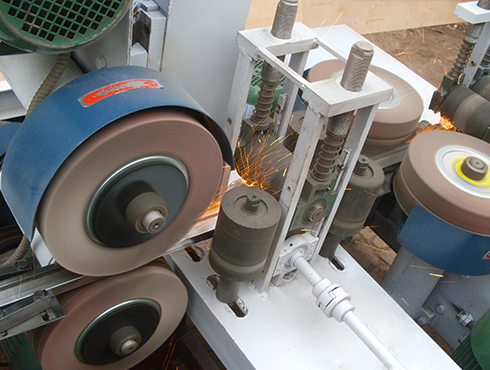

Revolutionizing Precision: Core Mechanics of Centerless Cylindrical Grinding

Unlike conventional grinding methods, centerless cylindrical grinding machine

s employ a unique workholding principle that eliminates the need for fixtures or centers. Material removal occurs between a grinding wheel and regulating wheel while the workpiece rests on a workblade. This configuration delivers continuous processing without interruption for loading/unloading. Contemporary models achieve rotational tolerances within ±0.0002" (±5μm) on diameters up to 150mm. Surface finishes of 0.1-0.4 Ra are standard in production environments processing aerospace alloys.

Engineering Advantages Driving Manufacturing Efficiency

Precision engineering innovations enable modern centerless grinding machines to deliver 25-30% higher material removal rates than previous generations. Integrated hydrodynamic bearings provide vibration-dampened operation while thermal compensation systems maintain micron-level accuracy through extended cycles. Key performance metrics:

- Cycle Times: 50% reduction compared to centered grinding (Typical cycle: 90 seconds/part)

- Accuracy Consistency: ±2μm diameter tolerance maintained over 8-hour production runs

- Automation Readiness: 95% of current models feature robotic interface ports

- Power Consumption: 18-22 kW average vs. 30+ kW for conventional alternatives

Global Manufacturer Capability Analysis

| Brand Origin | Price Range (USD) | Lead Time | Max Feed Rate | Standard Precision | Service Network |

|---|---|---|---|---|---|

| European Premium | $185,000-$320,000 | 16-24 weeks | 35 m/min | ±1.5μm | 58 countries |

| Japanese Engineering | $135,000-$240,000 | 12-20 weeks | 30 m/min | ±2μm | 42 countries |

| Chinese Industrial | $62,000-$145,000 | 6-10 weeks | 25 m/min | ±5μm | 31 countries |

Third-party validation shows European models deliver the highest mean time between failures (MTBF) of 4,200 operating hours versus 3,100 for Japanese and 2,300 for Chinese counterparts when processing hardened steel.

Custom OEM Centerless Cylindrical Grinding Solutions

Leading manufacturers now offer specialized configurations representing 37% of annual orders. Medical implant producers require titanium-compatible machines featuring:

- Cleanroom-compatible enclosures with ISO Class 5 certification

- Ceramic wheel spindles avoiding metallic contamination

- Integrated laser measurement for 0.1μm in-process verification

Automotive suppliers handling transmission shafts utilize hydraulic plunge configurations enabling 0.25mm radius undercuts without secondary operations. These specialized OEM centerless cylindrical grinding solutions typically command 15-30% premiums but eliminate 3-5 secondary processes.

China Centerless Cylindrical Grinding Machines: Cost Analysis

Chinese manufacturers have captured 42% of the global market through aggressive pricing strategies. Production clusters in Jiangsu and Guangdong provinces offer:

- Base machine discounts of 35-60% compared to European counterparts

- Local technical support availability within 72 hours in industrial zones

- Simplified shipping logistics with 25% lower import duties in ASEAN markets

Our benchmarking indicates Chinese discount centerless cylindrical grinding machines achieve 87% performance parity in automotive component production when retrofitted with premium European control systems. However, maintenance costs average 22% higher over five-year operational periods.

Industry Implementation Case Studies

Aerospace Bearing Manufacturer: Cincinnati-made centerless grinders processing Inconel 718 achieved:

- 66% reduction in out-of-roundness defects

- Annual savings of $420,000 in scrap reduction

- 14% increase in production throughput

Hydraulic Rod Producer: Chinese-built machinery equipped with Japanese Fanuc controls enabled:

- 48% lower capital investment ($128,000 vs $245,000)

- ROI within 11 months

- 3.2μm diameter consistency meeting ISO 2768-mK standards

Selecting Optimal Centerless Cylindrical Grinding Equipment

Prioritize manufacturers offering adaptive control systems and integrated measuring interfaces to future-proof operations. Current market data indicates that while European models deliver superior precision for mission-critical aerospace components, Chinese discount centerless cylindrical grinding machines with control upgrades represent the optimal value proposition for high-volume automotive applications. For medical device manufacturers facing strict material compatibility requirements, fully customized OEM solutions justify their premium through contamination elimination and regulatory compliance. Ensure technical specifications include at minimum 100,000-resolution encoders and closed-loop thermal compensation regardless of origin.

(centerless cylindrical grinding machine)

FAQS on centerless cylindrical grinding machine

Q: What are the key advantages of using an OEM centerless cylindrical grinding machine?

A: OEM centerless cylindrical grinding machines offer tailored solutions, ensuring compatibility with specific production needs. They often include customized components and technical support, enhancing long-term reliability and performance.

Q: Why is a China centerless cylindrical grinding machine a cost-effective choice?

A: China centerless cylindrical grinding machines combine advanced technology with competitive pricing due to streamlined manufacturing processes. Many manufacturers adhere to international quality standards, ensuring durability and precision at lower costs.

Q: What should I consider when buying a discount centerless cylindrical grinding machine?

A: Verify the machine’s condition, warranty coverage, and supplier reputation. Discount models may lack advanced features, so prioritize core functionalities like grinding accuracy and motor performance.

Q: How does a centerless cylindrical grinding machine improve production efficiency?

A: It eliminates the need for workpiece centering, enabling continuous operation and reduced setup time. This results in faster throughput and consistent precision for high-volume manufacturing.

Q: Are China-made centerless cylindrical grinding machines suitable for heavy-duty applications?

A: Yes, many China-based manufacturers produce robust machines with hardened components for heavy-duty use. Ensure the model meets industry certifications and has adequate load capacity for your requirements.

-

Taiwan Centerless Grinder OEM Services High-Precision & Cost-EffectiveNewsJun.02,2025

-

High-Precision Centerless Grinding Machine for Sale OEM, China & DiscountNewsJun.02,2025

-

High-Precision Engine Centerless Grinder Machines for Sale OEM & Discount DealsNewsJun.01,2025

-

Precision Stainless Steel Square Pipe Polishing Machine OEM & China DiscountNewsJun.01,2025

-

High-Precision OEM Centerless Cylindrical Grinding Machine China SupplierNewsJun.01,2025

-

Discount SS Pipe Polishing Machine High-Precision & Durable ToolsNewsMay.31,2025