In today’s competitive manufacturing world, businesses are continually searching for ways to improve both the efficiency and quality of their production lines. Tube polishing machines are at the forefront of these efforts, offering solutions that streamline operations while ensuring a high-quality finish.

The Role of Tube Polishing Machines in Boosting Efficiency

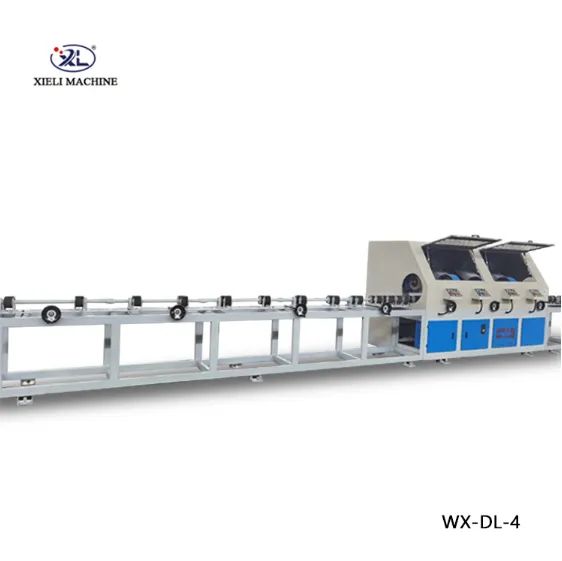

A tube polishing machine is designed to enhance the surface finish of tubes, ensuring a smooth, shiny appearance. This process is critical for industries where aesthetic appeal and quality are paramount, such as in the automotive, aerospace, and medical sectors. With the ability to remove scratches and imperfections from tubes, these machines improve both the visual and structural integrity of the material.

The efficiency of tube buffing machines is unmatched in these high-demand environments. By reducing manual labor and minimizing errors, these machines increase production output while ensuring that each tube meets stringent quality standards. They are designed to handle a range of pipe sizes, making them versatile for different applications and improving overall workflow.

The Versatility of Pipe Polishing and Buffing Machines

When it comes to polishing metal pipes, versatility is key. A pipe polisher or pipe buffing machine offers the flexibility to handle various pipe shapes and sizes, whether you're working with round, square, or even custom-shaped pipes. The ability to polish different materials, including stainless steel and aluminum, makes these machines valuable assets for manufacturers.

Moreover, specialized machines like the SS pipe buffing machine are designed specifically for the unique needs of stainless steel. Stainless steel pipes require a high-quality, reflective finish that only a machine built for this purpose can provide. These machines ensure that the final product has an impeccable surface, free from defects and ready for immediate use in applications that require precision and durability.

Achieving Superior Finish with Tube Buffing Machines

A tube buffing machine plays a crucial role in the final polishing stages of tube processing. It uses advanced abrasives and polishing wheels to achieve a mirror-like finish on the surface of the tube. This process is essential in industries that demand flawless finishes, such as in the production of high-end kitchen equipment, medical tools, and automotive parts.

The precision of these machines ensures that every tube receives a consistent finish, which is vital for maintaining uniformity in mass production. By investing in the right tube buffing machine, manufacturers can drastically reduce the time spent on manual polishing while achieving higher standards of quality.

Maximizing Output with Automated Pipe Polishing Machines

In high-volume production environments, automation is a game-changer. Automatic pipe polishing machines can perform tasks much faster than manual methods, drastically improving production rates. These machines are equipped with features that allow for continuous operation, reducing downtime and ensuring a seamless workflow.

Automation also allows for better control over the polishing process, meaning manufacturers can achieve a consistent, high-quality finish across multiple products. Whether you are polishing stainless steel or other materials, automated machines like the pipe polisher or tube polisher ensure efficiency without compromising on quality.

The Future of Tube Polishing: Innovation Meets Quality

The future of tube polishing machines is bright, with continuous innovations making them even more efficient and user-friendly. Manufacturers are increasingly looking for ways to integrate artificial intelligence and machine learning into their polishing processes. These advancements will allow for even greater precision, consistency, and speed, ensuring that each tube or pipe is polished to perfection.

As industries grow and the demand for higher-quality finishes increases, the evolution of tube polishing machines will continue to play a crucial role in shaping the future of manufacturing. Whether it’s an SS pipe buffing machine or a tube polisher, these machines are indispensable tools for creating the flawless, high-quality products that meet the needs of modern industries.

Tube polishing machines are essential tools in many industries, delivering both speed and precision to meet the growing demand for high-quality metal products. With innovations like the pipe polisher, manufacturers are able to improve their production efficiency while ensuring that their products maintain an impeccable finish. The future of tube polishing is bright, offering endless opportunities for manufacturers to optimize their processes and achieve the high standards of quality demanded by today's markets.