-

Products Detail

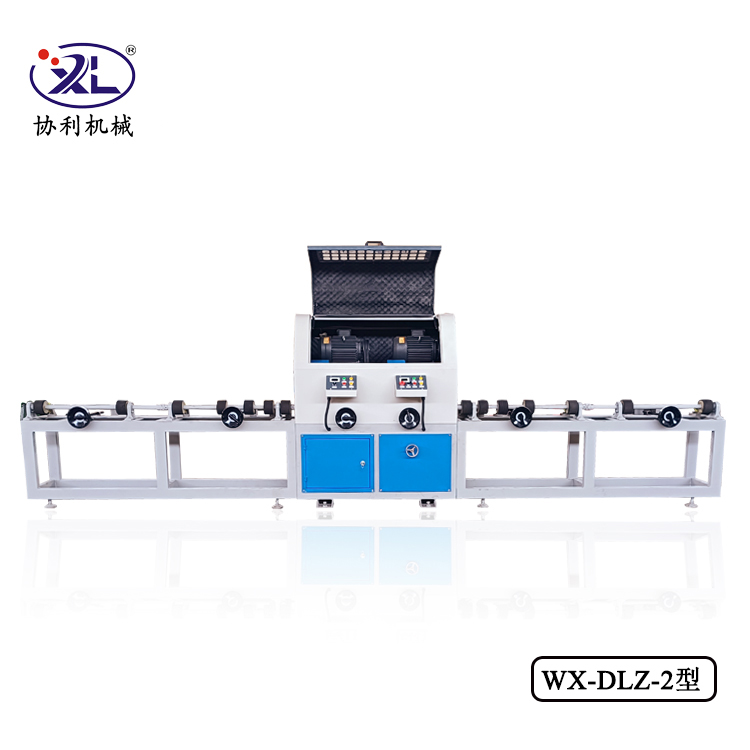

WX-DLZ Series Multi-station Vertical Polishing Machine

Main purpose and scope of application:

Round tube polisher is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. Round tube polisher is the best choice for polishing the round pipe, round rod and slender shaft. Round tube polisher can be equipped with a variety of polishing wheels, such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA etc. the guide wheel is stepless speed control, simple and convenient operation, and the steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dedusting fan or a wet dedusting system, which can be matched with an automatic loading and unloading mechanism according to the length of the processed parts.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DLZ-2

WX-DLZ-4

WX-DLZ-6

WX-DLZ-8

WX-DLZ-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

8.6

18

26.5

35.5

44

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel specification

110*70 (mm)

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

10-150

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Processing length(mm)

300-9000

Wet water cycle dust removal

optional

Dry fan dust removal

optional

Grinding head

feeding mode

Digital display electric adjustable

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weightabout(kg)

800

1600

2400

3200

4000

Equipment dimension

1.4*1.2*1.4

2.6*1.2*1.4

3.8*1.2*1.4

5.0*1.2*1.4

6.2*1.2*1.4

A brief introduction of stainless steel round tube polishing machine

Stainless steel pipe polishing machine is a machine used for polishing the surface of stainless steel pipe. Its main function is to remove the rough, scratched or oxidized part of the stainless steel pipe surface, so that the pipe surface becomes smooth and bright, to beautify and improve the purpose of practical value.Stainless steel tube polishing machine is an efficient machine, which is mainly used for polishing the surface of steel, stainless steel and other metal products, which can completely remove impurities such as burrs, oxide skin, and watermarks on the surface of metal products, and can also add luster and smoothness to the surface of metal products, improve surface quality and grade. Stainless steel round pipe polishing machine is suitable for railway, machinery, automobile, construction and other manufacturing fields, is a very important surface treatment equipment.

Structure and working principle of stainless steel round tube polishing machine

The main components of stainless steel pipe polishing machine include motor, wheel, electric control system, etc. Turn the tube over, hold the inside of the tube through multi-point positioning, and then contact the surface of the tube with the polishing wheel to achieve efficient polishing of the surface of the tube.

The polishing wheels of round tube polishers are usually made of a variety of different types of fiber and resin materials. These polishing wheels have different polishing effects, such as the ability to remove burrs, oxidation and watermarks, while also making the surface smoother with high brightness. When used, the stainless steel round tube polisher combines the wheels together, allowing precise polishing of the inner surface through different speeds and rotation directions.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Afrikaan

- Albaaniyaan

- Amxaari

- Carabi

- Armeeniyaan

- Asarbayjaan

- Basque

- Belarusiyaanka

- Bengali

- Bosnia

- Bulgaariya

- Catalan

- Cebuano

- Shiinaha

- Shiinaha (Taiwan)

- Korsican

- Croatian

- Czech

- Danish

- Dutch

- Ingiriis

- Esperanto

- Istooniyaan

- Finnish

- Faransiis

- Frisian

- Galiciyan

- Joorjiyaan

- Jarmal

- Giriig

- Gujarati

- Haitian Creole

- Hausa

- hawiye

- Cibraaniga

- Maya

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- iriish

- Talyaani

- Jabbaan

- Javanese

- Kannada

- Kazakh

- Khmer

- Ruwanda

- Kuuriya

- Kurdish

- Kyrgyz

- Foosha

- Laatiinka

- Latvia

- Lithuanian

- Luxembourgish

- Masedooniyaan

- Malagasy

- Malaay

- Malayalam

- Malta

- Maori

- Marathi

- Mongoliyaan

- Myanmar

- Nepali

- Noorwiiji

- Noorwiiji

- Occitan

- Pashto

- Faaris

- Polish

- Boortaqiis

- Punjabi

- Romanian

- Ruush

- Samoan

- Scottish Gaelic

- Seerbiyaan

- Ingiriis

- Shona

- Sindhi

- Sinhala

- Slovakia

- Islovenian

- Somali

- Isbaanish

- Sundanese

- Sawaaxili

- Iswidish

- Tagalog

- Taajik

- Tamil

- Tataarka

- Telugu

- Thai

- Turki

- Turkmen

- Yukreeniyaan

- Urduu

- Uighur

- Uzbekistan

- Vietnamese

- Welsh

- Caawin

- Yiddish

- Zulu