Round Pipe Metal Polishing Machine For Steel Tube

Stainless simbi pombi polishing muchina muchina unoshandiswa kupukuta pamusoro pepombi yesimbi isina tsvina. Basa rayo guru kubvisa rough,

Auto Metal Round Steel Bar Pipe Polishing Machine

Stainless simbi yakatenderera pombi polishing muchina midziyo yekupukuta pombi yakatenderera. Iyo yakakwenenzverwa pamusoro pepombi yakatsetseka uye yakajeka, iyo inosangana nemimwe indasitiri zviyero. Zvinotevera zvichazivisa kushandiswa kwesimbi isina tsvina kutenderera chubhu yekupolisha muchina mune zvakadzama.

Round Bar Polishing Machine Factory Price

Simbi isina tsvina yakatenderedza pombi yekupolisha muchina imhando yemidziyo yekukwenenzvera kunze kwepombi yakatenderedzwa, iyo inonyanya kushandiswa kukwenenzvera pamusoro pepombi, pombi yesimbi, simbi isina tsvina pombi, simbi bar, aluminium uye zvimwe zvigadzirwa, izvo zvinobudirira kuvandudza kupedzwa kwepamusoro uye kutaridzika kwemhando yechigadzirwa. Iri bepa rinosuma musimboti, mashandisirwo, chimiro, kushanda uye kugadzirisa kwecylindrical chubhu yekupolisha muchina, tichitarisira kukupa imwe referensi uye rubatsiro.

Stainless Simbi Round Pipe Tube Polisher Machine

Iyo cylindrical chubhu yekupelisha muchina inowanzo umbwa nefuremu, mota, chinoderedza, rotor, vhiri rekukuya, spindle, abrasive hopper uye zvimwe zvikamu, izvo zvinotsanangurwa zvakadzama pazasi.

SS Tube Kupukuta Muchina Mirror Buffing Machine

Due to the improvement of the roughness of the cylindrical tube polishing machine, the noise and accuracy tendency can be significantly reduced during operation. Assuming that the hardness of the steel surface is not uniform or the characteristics are different, it usually forms polishing difficulties. The cylindrical polishing machine quantifies and sets the pressure value to determine the loading pressure of the sample surface; The cylindrical polishing machine not only eliminates the vibration and noise generated by the grinding and polishing machine at high speed, but also ensures a durable high flatness.

Carbon Simbi Pipe Kupolisha Machine Tube Polisher

High polishing efficiency: stainless steel round tube polishing machine has the characteristics of high efficiency, which can make the inner surface of the round tube efficient polishing treatment in a short time. This can not only improve production efficiency, but also reduce the manufacturing cost of the product.

Auto Steel Pipe Tube Outer Wall Polishing Machine

Stainless steel pipe polishing machine is a special equipment for polishing stainless steel pipes. It can form a smooth polishing layer on the surface of the pipe, so that the surface of the pipe shows a bright and smooth effect, so as to improve the quality and beauty of the pipe. Let's take a closer look at the related content of the stainless steel pipe outer circle polishing machine.

SS Round Pipe Ngura Kubvisa Kupolish Machine Mutengo

Round pipe polishing machine is a kind of mechanical equipment specially used for polishing round materials such as steel pipe and stainless steel pipe. Automatic loading and unloading rack is an improved version, which can be automatically loaded and unloaded in the processing process, greatly improving production efficiency and work efficiency. Below, we will introduce the related content of the round tube polishing machine with automatic loading and unloading rack.

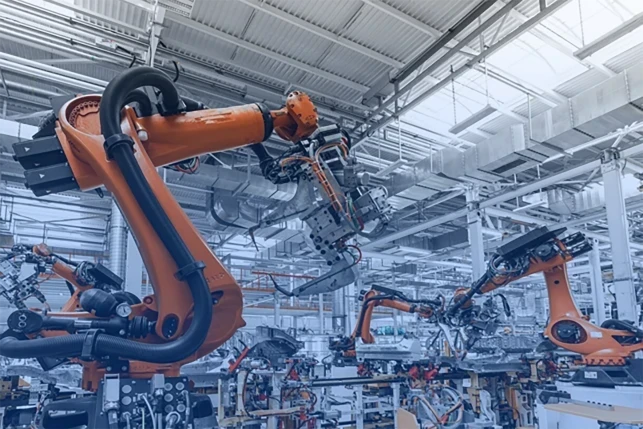

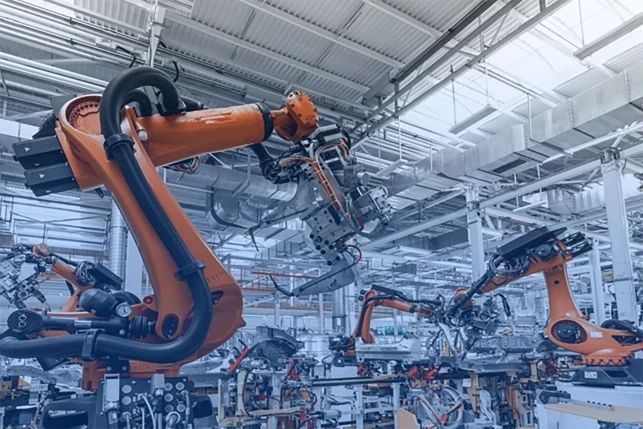

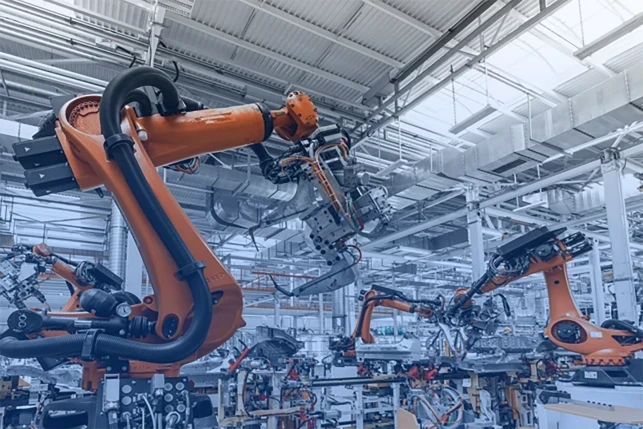

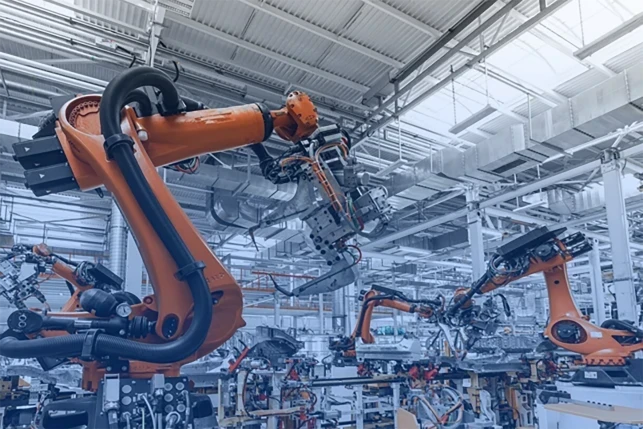

The Multi-station Vertical Round Tube Polishing Machine is specifically designed for the surface treatment and finishing of round metal tubes in various industrial applications. It is widely used in sectors such as stainless steel furniture, decorative hardware, fitness equipment, medical devices, and architectural handrails. This machine is capable of handling tubes made from stainless steel, aluminum, copper, and other metal materials, providing smooth, uniform, and high-gloss finishes. Whether the goal is to achieve a mirror-like polish or a fine satin texture, the machine delivers consistent and high-quality results.

With its multi-station setup, the machine allows simultaneous operation of several polishing heads, significantly improving efficiency and reducing labor costs in large-scale production environments. Its vertical design ensures precise tube alignment and optimal pressure distribution during polishing, resulting in even surface treatment without deformation. This makes it ideal for manufacturers with high-volume demands who require both speed and surface precision. The machine can also be integrated with automatic feeding and dust collection systems, further enhancing productivity, cleanliness, and safety in the workplace.