Aħbarijiet

Xingtai Xieli Machinery Manufacturing Co., Ltd.

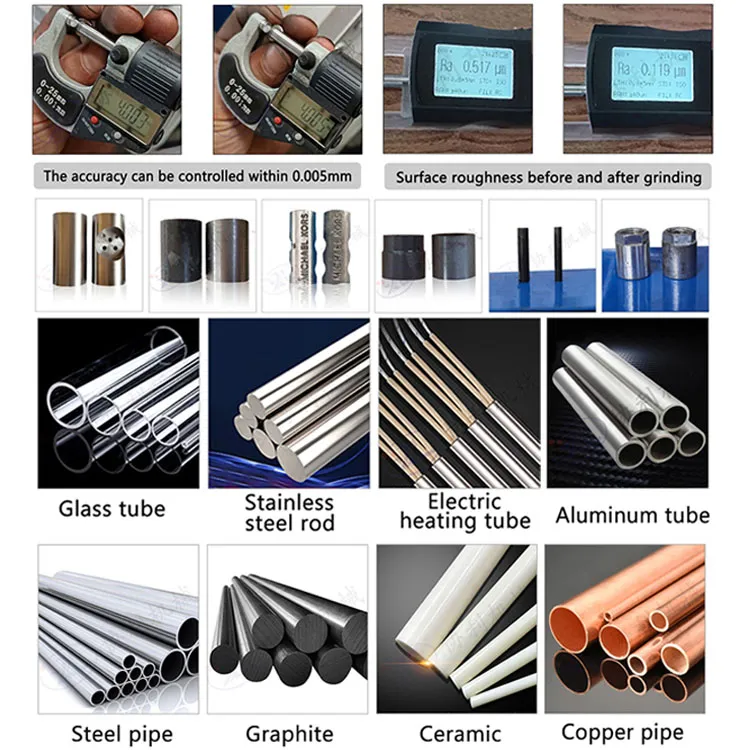

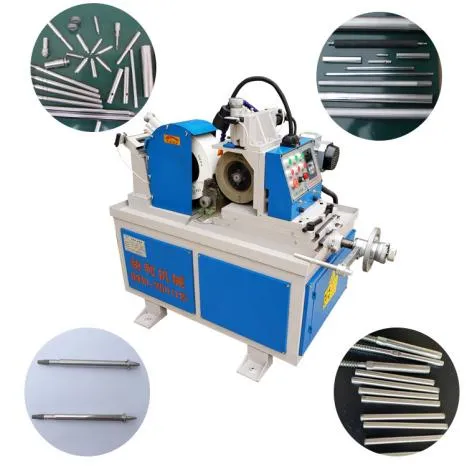

Xingtai Xieli Machinery Manufacturing Co., Ltd. specializes in the production of large/small diameter round pipe polishing machine, small centerless grinder, large diameter cylindrical polishing machine, centerless polishing machine, square pipe polishing machine, hexagonal polishing machine, plane polishing machine, ball polishing machine, abrasive belt polishing machine, shaped parts polishing machine polishing equipment, the company is located in North China machinery manufacturing town Xingtai high-tech Industrial Development Zone, Hebei.