In the kitchen equipment manufacturing industry, stainless steel square tubes are commonly used to manufacture the framework, support structure, and piping system of kitchen equipment. The functions of stainless steel square tubes include:

- Framework and Support Structure: Stainless steel square tubes can be used to manufacture the framework and support structure of kitchen equipment, such as workbenches, shelves, stove brackets, etc. Due to its corrosion resistance, high temperature resistance, and structural stability, stainless steel square tubes can ensure the stability and durability of kitchen equipment.

- Pipeline system: Stainless steel square pipes are also commonly used in the manufacturing of kitchen equipment pipeline systems, such as gas pipelines, drainage pipelines, and ventilation pipelines. Stainless steel pipes have the characteristics of corrosion resistance and good hygiene, which are suitable for use in kitchen environments and can ensure food safety and hygiene.

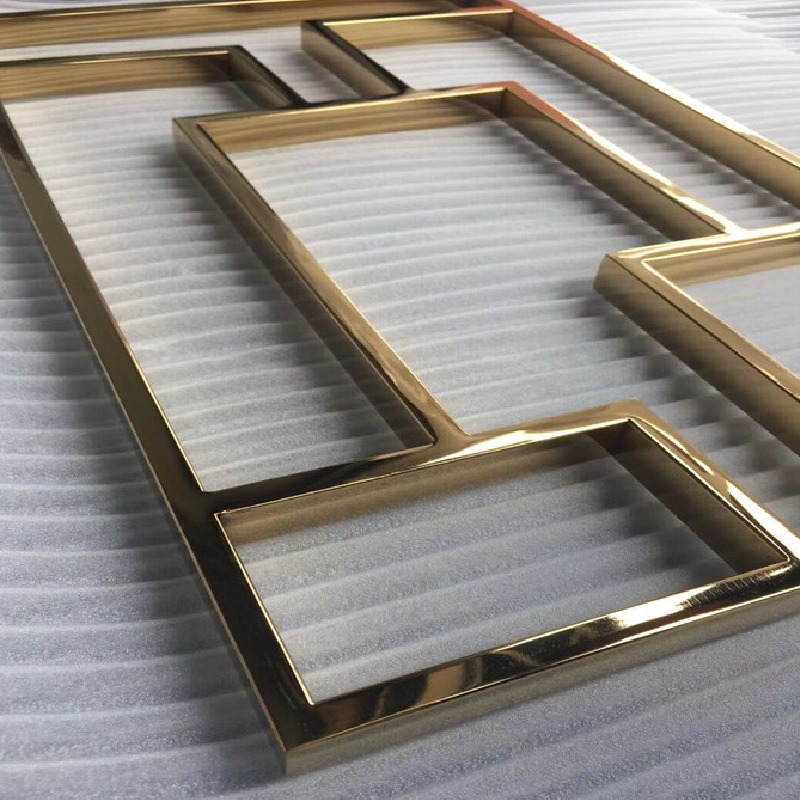

- Surface decoration: Stainless steel square tubes can also be used as surface decoration materials for kitchen equipment, used to make door frames, handrails, decorative frames, etc. Stainless steel has the characteristics of luster and easy cleaning, which can improve the appearance and hygiene of kitchen equipment.

Therefore, stainless steel square tubes play an important role in the kitchen equipment manufacturing industry. They play a crucial role in the structure, piping system, and exterior decoration of kitchen equipment, while also meeting the requirements of kitchen equipment for corrosion resistance, hygiene, and aesthetics.

In summary, square tube polishing machines are widely used in various fields such as building decoration, pipeline manufacturing, home furniture, automotive parts, kitchen equipment, etc., playing an important role in improving the surface quality and appearance of products.