At Xingtai Xieli Machinery Manufacturing Co., Ltd., our stainless steel pipe polishing machine represents decades of specialized expertise in metal finishing technology. As industry pioneers, we've perfected the art and science of transforming raw stainless steel tubes into precision-finished products through our advanced stainless steel pipe polisher systems. The stainless steel tube polisher solutions we manufacture today carry forward a legacy of innovation that began with our founders' vision to revolutionize surface finishing processes. This article explores how our commitment to engineering excellence, sustainable manufacturing, and customer-focused innovation has established us as global leaders in stainless steel polishing technology.

The Engineering Heritage Behind Our Stainless Steel Pipe Polisher Development

The evolution of Xingtai Xieli's stainless steel pipe polisher technology traces back to our early recognition of the growing need for precision finishing in sanitary piping systems. Our engineers observed the limitations of conventional polishing methods in achieving the flawless surfaces required for food processing, pharmaceutical, and architectural applications. This insight drove us to develop the first generation of specialized stainless steel tube polisher equipment that set new benchmarks for surface quality. Today, our polishing systems incorporate generations of accumulated knowledge, with each machine embodying the lessons learned from thousands of installations worldwide. The continuous refinement of our technology demonstrates our core belief that true quality emerges from both technical mastery and practical experience in real-world applications.

|

ಯೋಜನೆ ಮಾದರಿ |

WX-DL-2 |

WX-DL-4 |

WX-DL-6 |

WX-DL-8 |

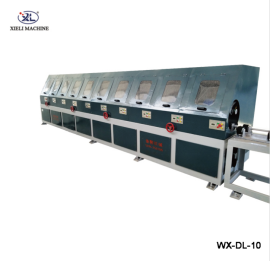

WX-DL-10 |

|

|

ಇನ್ಪುಟ್ ವೋಲ್ಟೇಜ್ (v) |

380V (ಮೂರು ಹಂತದ ನಾಲ್ಕು ತಂತಿ) |

|||||

|

Input power(kw) |

13.2 |

22.2 |

30.7 |

38.7 |

46.7 |

|

|

ಹೊಳಪು ಚಕ್ರ specification(mm) |

250/300*40/50*32(Width can be assembled) |

|||||

|

Guide wheel specification(mm) |

110 |

|||||

|

ಹೊಳಪು ಚಕ್ರ ವೇಗ (r/ನಿಮಿಷ) |

3000 |

|||||

|

Guide wheel speed(r/min) |

ಹಂತವಿಲ್ಲದ ವೇಗ ನಿಯಂತ್ರಣ |

|||||

|

ಯಂತ್ರದ ವ್ಯಾಸ (ಮಿಮೀ) |

20-360 |

|||||

|

Processing efficiency(m/min) |

0-8 |

|||||

|

Surface roughness (um) |

ದಿನ 0.02 |

|||||

|

Processing length(mm) |

Determined by bracket length (0.3-12) |

|||||

|

ಡ್ರೈ ಫ್ಯಾನ್ ಧೂಳು ತೆಗೆಯುವಿಕೆ |

ಐಚ್ಛಿಕ |

|||||

|

ಆರ್ದ್ರ ನೀರಿನ ಚಕ್ರ ಧೂಳು ತೆಗೆಯುವಿಕೆ |

ಐಚ್ಛಿಕ |

|||||

|

ರುಬ್ಬುವ ತಲೆ ಆಹಾರ ನೀಡುವ ವಿಧಾನ |

Digital display electromagnetic hydraulic control |

|||||

|

ನಿಷ್ಕ್ರಿಯ ಮಾರ್ಗದರ್ಶಿ ಚಕ್ರ ಹೊಂದಾಣಿಕೆ ವಿಧಾನ |

Manual/electric/automatic optional |

|||||

|

Machine tool total weight about(kg) |

2000 |

3000 |

4000 |

5000 |

6000 |

|

|

Equipment dimension(m) |

1.3*1.2*1.5 |

2.6*1.2*1.5 |

3.9*1.2*1.5 |

5.2*1.2*1.5 |

6.5*1.2*1.5 |

|

Precision Engineering in Modern Stainless Steel Pipe Polishing Machine Designs

- Every stainless steel pipe polishing machinefrom Xingtai Xieli represents the pinnacle of mechanical engineering and surface treatment technology. Our current generation systems feature multi-stage polishing heads with independently adjustable pressure controls that accommodate varying material thicknesses and desired finish levels.

- The stainless steel pipe polisherlineup includes innovative features like automatic diameter compensation systems that maintain perfect contact pressure as pipes taper or vary in dimension. We've developed proprietary abrasive belt tracking mechanisms that eliminate edge wear and extend consumable life significantly compared to conventional systems.

- The stainless steel tube polishercontrols incorporate intelligent software that learns from operator adjustments, automatically optimizing parameters for different stainless steel grades and surface conditions. These technological advancements ensure our machines deliver not just superior finishes, but unprecedented consistency across production runs.

Sustainable Manufacturing Practices in Our Stainless Steel Tube Polisher Production

- At Xingtai Xieli, environmental responsibility forms an integral part of our stainless steel tube polishermanufacturing philosophy. We've implemented comprehensive sustainability initiatives throughout our production facilities that reduce energy consumption and minimize waste generation. The manufacturing process for our stainless steel pipe polishing machine systems utilizes energy-efficient servo motors and regenerative braking systems that capture and reuse power during operation cycles.

- Our paint finishing department has transitioned to water-based coatings with zero VOC emissions, while the metal fabrication areas employ advanced filtration systems that capture and recycle 98% of metal particulates. The stainless steel pipe polishermachines themselves contribute to sustainable operations through features like optimized power consumption profiles and closed-loop coolant systems. These efforts reflect our broader commitment to developing solutions that benefit both our customers' operations and the global environment.

FAQS About Stainless Steel Pipe Polishing Machines

What stainless steel grades can your stainless steel pipe polisher process?

Our stainless steel pipe polishing machine systems are designed to handle all common grades including 304, 316, 430, and duplex stainless steels. The adjustable pressure controls and variable speed settings allow optimal processing of different alloy hardness levels while maintaining consistent finish quality across all materials.

How does your stainless steel pipe polisher achieve mirror finishes?

The stainless steel pipe polisher from Xingtai Xieli utilizes a precision multi-stage polishing process with progressively finer abrasives. Our patented contact wheel designs maintain perfect pressure distribution while specialized polishing compounds enhance the final luster. The result is consistent mirror finishes that meet even the most stringent sanitary standards.

What diameter range can your stainless steel tube polisher handle?

Our stainless steel tube polisher systems accommodate diameters ranging from small precision tubing to large diameter pipes. Custom configurations are available for special sizes outside our standard range, with adjustable tooling that maintains precision across the entire spectrum.

Can your stainless steel pipe polisher remove weld seams effectively?

Yes, our stainless steel pipe polishing machine systems include specialized configurations for weld seam removal and blending. The heavy-duty construction and high torque motors power through weld material while maintaining the surrounding surface integrity for seamless finishes.

What maintenance does your stainless steel pipe polisher require?

Xieli stainless steel pipe polisher machines are designed for minimal maintenance with easy-access service points. Routine care primarily involves abrasive belt changes and periodic lubrication. Our robust construction and premium components ensure years of reliable service with proper maintenance following our detailed guidelines.