The polishing process of using a round tube polisher before and after the round tube plating generally includes the following steps:

- Surface preparation: First of all, the surface of the round tube needs to be cleaned and treated to ensure that its surface is free of impurities, oxides or other undesirable substances. Cleaning can be done by chemical treatment or mechanical treatment, ensuring surface finish and quality.

- Pre-plating treatment: In the polishing process before plating, preliminary polishing treatment may be required. This may involve the use of equipment such as grinding tools or grinders to remove surface imperfections, roughness and inhomogeneity in preparation for pre-plating treatment.

- Plating treatment: Plating is the process of coating the metal surface with a layer of metal or alloy to improve its appearance, reduce oxidation and increase corrosion resistance. This step may include processes such as electroplating, hot dip plating, etc.

- Polishing treatment: In the polishing process after plating, it is usually necessary to carry out the final polishing treatment on the surface of the round tube. This may involve the use of dedicated round tube polishers and polishing media, such as polishing pastes or abrasives, to obtain a high finish and high gloss surface effect.

- Cleaning and drying: Finally, the polished tube needs to be cleaned and dried to remove the residue generated during the polishing process and ensure the final surface quality.

The above is the polishing process of the round tube polishing machine before and after the round tube plating under normal circumstances. The specific steps and processes may be adjusted according to the metal materials used, product requirements and equipment characteristics.

In 2016, a Turkish company invested in a carbon steel pipe project. Factory built in Turkey. The company requires that the surface of the carbon steel pipe be coated with 4-5 microns of chromium-nickel, which also needs to be polished before plating, and the finished carbon steel pipe is sold to Turkey and neighboring countries.

The customer has chosen to cooperate with Xingtai Xieli Machinery Manufacturing Co., Ltd. in China. The carbon steel pipe project in Türkiye needs not only the carbon steel pipe polishing machine equipment, but also the high-quality full-automatic pipe polishing machine. The adjustment of the grinding head should use the electric button adjustment method to improve production efficiency, as well as the water tank filter system to filter the polished magazines. It is also necessary to design an automatic feeding machine and automatic unloading machine device that can accommodate 400 workpieces for this purpose, and to prevent scratches and scratches on the carbon steel pipe. The design of the machine size should meet the requirements of the carbon steel pipe factory site and other complete design schemes. And this kind of technical assistance and design requirements can only be achieved by truly powerful manufacturers of Xieli Mechanical Pipe Grinding and Polishing Machines. Xingtai Xieli Machinery Manufacturing Co., Ltd., as a mature enterprise with advanced machinery manufacturing technology and many years of experience in its own factory, has successfully won the trust of the project leader in Türkiye.

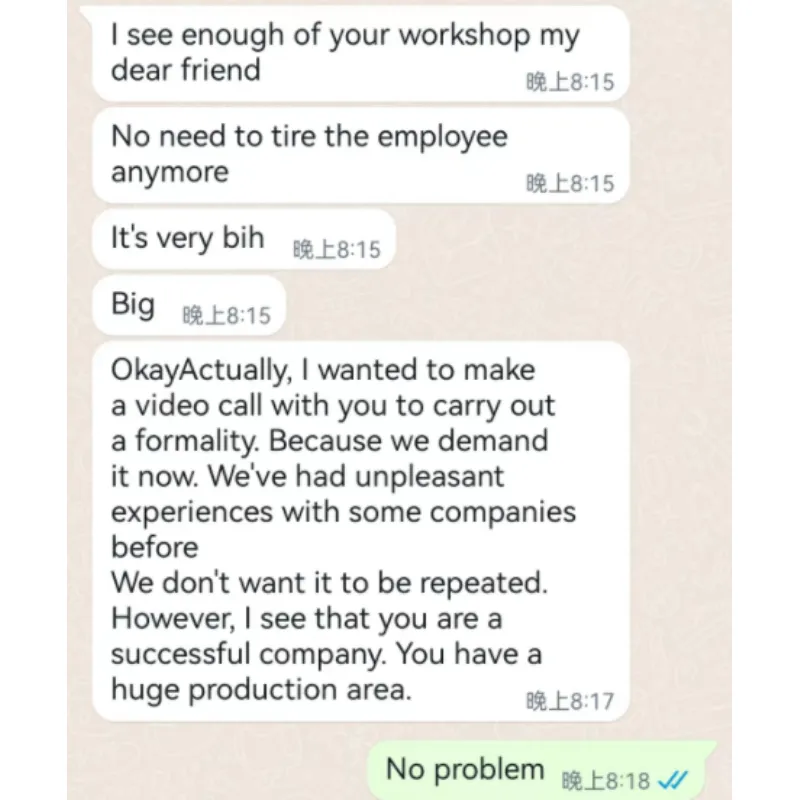

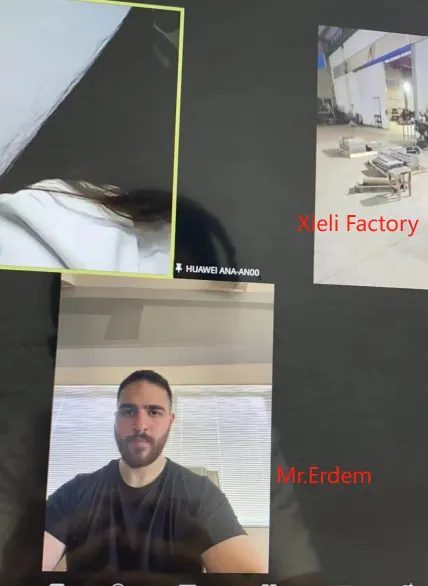

Mr. Erdem stated that he had previously signed contracts with other suppliers, but the suppliers deceived him and did not ship the goods to him. At the beginning of his contact, Mr.Erdem also communicated in detail with Xingtai Xieli Machinery with a trial attitude, and through the ZOOM online video conference, Mr. Erdem checked the physical factory of Xieli Machinery as well as the equipment inventory and spare parts inventory of the factory. He stated that Xieli Machinery has a large factory and good machine quality. Mr. Erdem is confident in cooperating with Xingtai Xieli Machinery. The following picture shows the chat records between Xieli Machinery and Mr. Erdem after a video conference.

On August 13, 2016, we signed a contract to purchase a fully automated six station round pipe polishing machine. And it is clearly stipulated that Xingtai Xieli Machinery should provide service plans such as design drawings, equipment connection diagrams, and remote assistance from technical workers to inspect the fully automatic round pipe polishing machine.

The business philosophy of Xingtai Xieli Machinery is always to put "customer needs" first. According to customer needs, Xingtai Xieli Machinery engineers provide a set of professional factory planning scheme according to the size, site layout, terrain area and other data of the Türkiye customer. This plan reflects the professionalism of Xingtai Xieli Machinery Product Design Department in terms of factory scale, water supply, power supply lines, energy consumption and other related technical information. Thanks to the meticulous and perfect marketing service features and the practicability and feasibility of the scheme, it has been recognized by Türkiye.

Shipped on September 12, 2016. The equipment is first transported to Shanghai, China, and then transported to Türkiye by sea.

After the equipment arrived in Türkiye, according to the contract, the technicians of Xingtai Xieli Machinery remotely guided the equipment installation and other work through the zoom conference.

The equipment has been put into production with good results. The considerate after-sales service department of Xingtai Xieli Machinery has established records for every customer, followed up in a timely manner, identified and solved problems, and relieved customers of their worries. Choosing Xingtai Xieli Machinery means choosing quality!